Hello I am going to be ordering a shapeoko 5 pro soon with the spindle. I am wondering if anyone has recommendations on what endmills I should buy to get started? I’m not quite sure yet what I am going to be working on but I know that signs, inlays, cutting boards, and some 3d carvings are are on my list so far. I’m finding it difficult to choose because there’s so much out there and I’m not sure what I’m going to need. Any help getting pointed in the right direction is much appreciated.

Hi,

Just start using a Shapeoko 5 3 months ago and here is the pack I order. The starter pack from Carbide 3D. All good for me.

Hi,

I ordered the Carbide 3D starter pack of cutters when I ordered my Shapeoko Pro 5. I’m new to CNC machining and haven’t found a use for all of them yet but it seems like a nice selection and all the feeds and speeds are pre-programmed in Carbide Create.

One of the things I’ve done with my machine is to make signs using Oramask film. I’ve found that “downcut” bits work best when using Oramask. The Amana 46200-K 1/8" downcut bit works well for this.

I used the 60 degree Vee bit that comes with Carbide 3D’s starter kit but found that it doesn’t provide as clean of a cut through the Oramask film which caused a lot of post-processing cleanup. I stumbled on Cadence Manufacturing’s website and they provide a downcut “Grovee” bits that work really well with Oramask.

https://www.cadencemfgdesign.com/shop

My CNC’s been down quite a bit from when I first received it back at the end of April due to issues with the VFD spindle (the bearings went on the spindle itself and then something died in the controller box). I’m currently waiting for a replacement of the controller box and hope to get back up and running soon!

Ya I have seen a few videos on using oramask and using downcut endmills and bits seems to be standard practice. I am looking forward to using it myself.

I have vcarve pro so I’m going to have to enter the bits in the software

Oramask can be expensive on Amazon. Like a dollar a foot. I found this place that has it much cheaper which can make a big difference if you use a lot of it.

Thank you for the tip.

I also have V-carve pro. I just had both the Vcarve and Carbide Create open and copied it over by hand.

If I were to do it again I would only buy three bits to get started:

1/4" down cut endmill

1/8" down cut

90 degree V bit

Any brand would do at first, however I really like the bits from C3D. I made the mistake of paying like $300 for an Amana set, these are the only three bits I used from the set…I only work with wood though and don’t do any 3D work.

Best advice I can give is to buy these three basic bits and then buy new bits only when necessary to complete a projects. Hope this helps.

I have a mixture of C3D, Amana and Cadence Manufacturing. The downcut bits from Cadence are great and the O flute bits from Amana are great on plastic.

SlimJen from Cadence was one of my favorites.

It’s a 1/8” bit on a 1/4” shank saving changing the collet.

Too bad I broke it but I will order another.

I’d tend to agree with the short list to get you started.

Find a vendor of decent cutters in your area, preferably a trade supplier who sells decent quality at sensible trade prices. Cutters are consumables, they will go blunt, how fast depends on which woods or other materials you’re cutting, and they’re not user sharpenable so you’ll want a supplier of decently priced cutters.

I’d also note, as I was learning to use my machine I committed a certain amount of cutter abuse and it’s nice to not trash expensive cutters as you learn.

Over here on the East side of the Atlantic I found these folks who do commodity cutters, with nice DLC coatings at very sensible prices

The Amana cutters are probably better quality, but I’m not sure I’d pay more for a consumable wearout component unless I had some specific requirements.

And these folks for more ‘commercial grade’ cutters

Both of them ship for delivery the following morning, I’m sure there are some similar suppliers near you.

That is great advice!

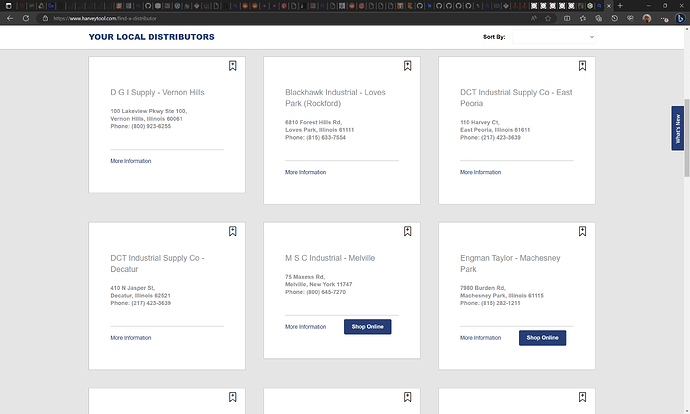

When I was just starting out, I used Harvey’s “Find a distributor” page to find a local shop which was willing to allow me to drop by and give them a check for some endmills, which I then picked up after their next shipment came in.

The sales folks were also generous enough to give me a stack of catalogs which I found very informative, both in terms of what tooling was available, and general guidelines for usage.

I agree with this. I’m brand new and these are the bits I use the most. I did just order a bowl bit because I need it for a certain project.

Is there anything in the Chicago area that anyone would recommend for endmills?

Great recommendations. Couple new vendors for me to try.

Go to:

click on “Illinois” in the map:

there are more further down.

Whether or no these folks will be willing to do business w/ an individual would have to be determined by checking in w/ them.

Nothing in the Southeast apparently

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.