That’s a tall order. I’ll try my best with this but I’m not sure it’s possible to get there.

So a bit of background. In most cases with a tool designed for non-ferrous metals in this size you can get down to around a 0.0003" (0076mm) chipload and not be rubbing. They will like higher numbers but that’s our floor. This is exacerbated in this case by the steel cutter design and runout. In order to actual cut and not grind away material we have to have a chip that’s at least bigger than the chip we are making. A steel cutter typically has a bigger edge radius to strengthen the edge. Runout gets added and subtracted from different flutes at different rotational positions, more so with a helix (flute twist). So we have to assume that we are going to both take a chip plus the runout and a chip minus the runout in each cut.

This is not meant as derogatory to the Makita or Makita clones. But one of the areas they are not great in is runout. There’s too steep of an angle with too little engagement length of the collet for consistent low runout. At a minimum I have to assume 0.0005" (0.013mm) runout regardless of collets. With customers we have tested with it’s a bit variable but it’s usually over double that.

So let’s assume that you have a really good router and collet with only 0.0005" (0.013mm) of runout. We’ll also assume an aggressive steel tool that we only have to hit a 0.0004" (0.010mm) chipload with. That would make our feed based on a 0.0009" (0.022mm) chipload and give us a big chip of 0.0014" (0.036mm) and a small chip of 0.0004" (0.010mm). If we convert that into a feed we get 54IPM (1371mm/m) with the 30K of the router. If we go down to the minimum of 12K we get 21.6IPM (549mm/m). But that’s only if we are taking at least a 50% of the tool diameter in radial (stepover). In the case of an 0.1mm cleanup pass we are only taking about 13%. So our actual chipload drops to 0.0006" (0.015mm). To compensate we need to increase our chipload up to ~0.00134" (0.034mm) to actually get our 0.0009" (0.022mm) programed feed. That works out to 80.5IPM (2045mm/m) at 30KRPM or 32.2IPM (818mm/m) at 12KRPM.

With those numbers there’s no way the machine will be able to keep up in that tight of a space with the 80.5IPM (2045mm/m). So our best bet is probably the 12KRPM at 32.2IPM (818mm/m). To be clear I can’t be sure that it will be able to maintain that feed either but we have much better odds there.

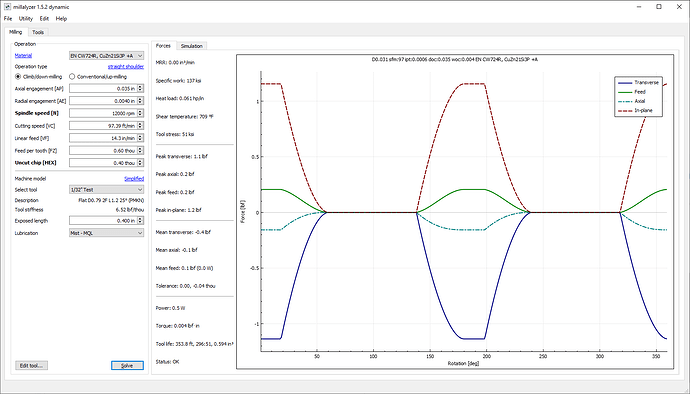

Let now look at Millalyzer to see if we are crazy. Have to use a silicon brass as it’s the closest thing there. Your H62 should be slightly easier on forces but want slightly more chipload.

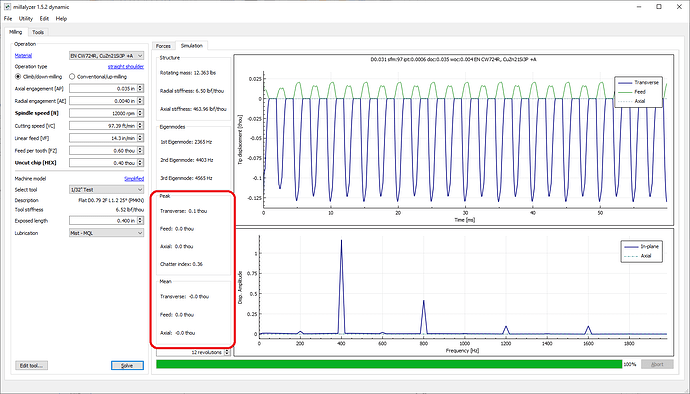

Small chip:

We are mostly ok here and we expect a peak deflection of 0.0001" (0.0025mm) into conventional.

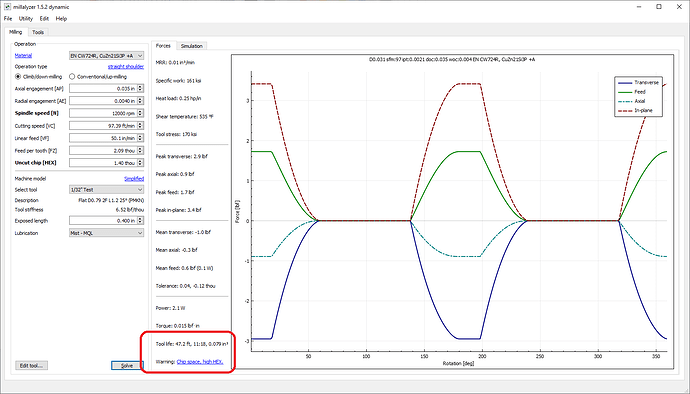

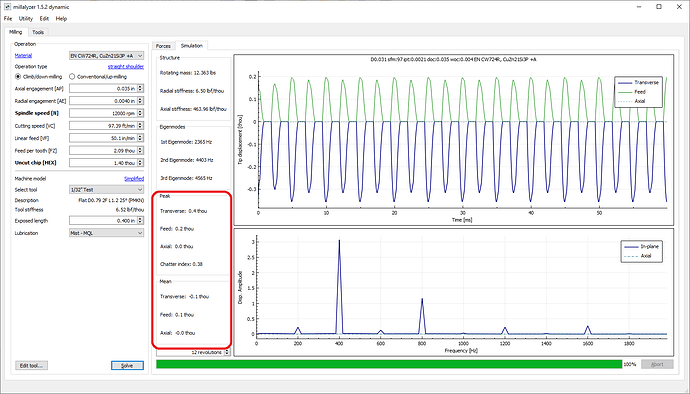

Large chip:

We do have some potential issues here. It’s warning us we might not have enough room in the flute of the cutter for the chips we are making. This being a steel cutter that may be true and we might compress them some. Might be ok as we are ejecting them out the back since this is a cleanup pass. Additionally, we won’t have this chipload across the whole flute as the helix will change the amount of runout across any single flute. Can’t say completely as I don’t have one of those cutters to inspect.

We have also increased the deflection on the tool up to 0.0004" (0.010mm).

If we have to assume for more runout we probably don’t have enough room to actually use the tool as a cutter. At least not with the steel cutter geometry and a full plunge. If you have to use the tool as a grinder you will actually have more forces and therefor more deflection even though you are removing less material. Keep in mind too that whatever your runout is will add to both sides of the cut.

Other solutions to this would be a single flute tool as they only have to deal with the runout in plunge and certain direction changes. Lower runout but that’s not an easy ask. A more aggressive cutter geometry to give us more space and a lower minimum chipload. Multiple passes to lower our forces and let us take larger chips.

All of the above is me assuming a lot. I used a fair generic steel geometry with a fairly aggressive edge radius just to make it work at all. If it’s a big blunt edged tool it will still grind as the edge can’t get under the chip.

Don’t know what kind of coolant you are using in the mist setup. If it’s a proper oil based one with a surfactant that will actually give you a smaller possible minimum chip. If it’s just a “chemical” fluid or alcohol/water that will just lower the temp. Though, those will let you use the tool as a grinder more without melting.

I hope that’s marginally useful. Let me know if you want me to expand on something or have any questions.