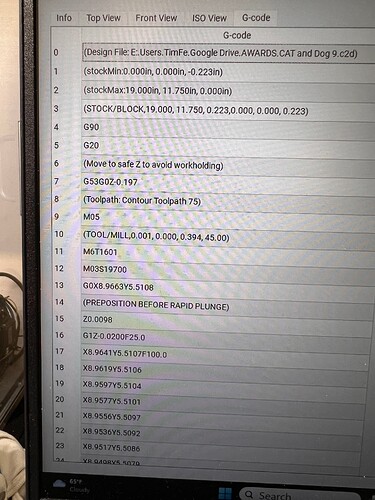

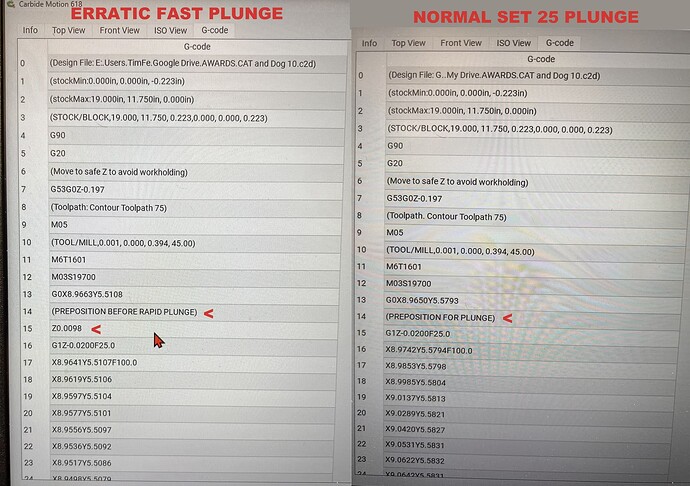

Experiencing an Erratic Plunge Rate at a speed far greater than that assigned to the tool in the toolpath. This usually occurs on the first drop/path in the file. I went as far as assigning a 25.0 rate for all the tools in the file in an attempt to better identify the issue. The initial plunge is significantly faster. If I reopen the path and set the tool by retyping 25.0 or any other number, it will correct if I restart the job. I have attached a photo of the code when the incident occurred. Has anyone come across this issue? 5 Pro

Please post the .c2d file here or mail it to support@carbide3d.com

Which machine do you have?

What Z-axis?

Is it mechanically sound?

All wiring in good condition?

What feeds and speeds? from where?

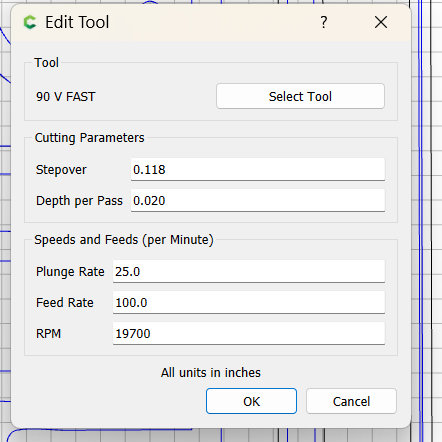

Post a screengrab of your tool definition for tool #1601?

It is a 5 Pro, so I believe it is in sound and excellent condition. This has happened in most files I have used for the last couple of months, just have not wanted to deal with it due to time. Attached is the tool 1601 which is a 90-degree V bit I use for engraving on acrylic. My tool file is customized to make sense regardless of bit brand.

The plunge rate for soft plastic on a Shapeoko HDM is 20 IPM — might try pulling back to that.

Things to check:

Z-axis lubrication: CNC Machine Maintenance

Z-axis motor wiring — usually wiring problems are accompanied by awful noises

mechanical issues — make sure all hardware is secure and that nothing is interfering mechanically

Make a video and send that to us at support@carbide3d.com along w/ a link to this thread?

Thanks, Will, all that stuff is good I use the machine daily and have lubed it up a couple of times. Don’t believe it to be mechanical as there is no tell-tell sign it is in any way. 25 works perfectly for me with all the bits I use on acrylic, not like 75 or more which is the issue. It’s like the machine is not recognizing the file entry and just plunging with a prefixed number on the first drop.

Your GCode shows a rapid Z plunge to a very tiny amount above Z Zero, then a toolfeed plunge into the material. I think this is the correct behavior, assuming Z Zero is top of material.

Is your retract height accidentally set to some unusually small amount? It looks like it’s set to about 0.01", about 1/4 of a mm.

Thanks for your observation, the retract is set to .5", and that particular drop was different in that it reverted to the file slightly above the material. The issue that I am having is that the plunge speed does not change. However, with your input, I dug further into it and believe I have resolved the problem as follows.

Not Solved, see next response.

Well, believe I have found the solution. I use CC on 3 computers; one in the office at the shop, another at home, and of course one connected to the machine. Google Drive is used to share the latest file created among the 3. I create drawings on both the freestanding units daily, but, only edit with the one on the machine during the cut. I noticed that the machine selection was changing to a Shapeoko 3 in the CC V 256 files despite being set to 5 Pro originally. The culprit was found to be an outdated version of CC on the machine computer that was saving the files as a Shapeoko 3 when I saved after edit. This may be the reason of running into some feed speed I have experienced as well.

Will and Michael thanks for your support!

Unfortunately, this has not been resolved despite my last post. The issue remains the same as outlined. When the fast plunge occurs Z0.0098 appears on the line after “Preposition Before Rapid Plunge”.

When operating normally to the file indicated plunge speed, Z0.0098 and “Rapid” do not appear in the G-Code.

Resetting the retract height does not change the issue.

Where does the Rapid Plunge Z0.0098 directive come from?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.