Has anyone seen this type of error code? I’m using esprit cam. I haven’t used it in a while, but have been successful in the past but that was only doing basic waste board facing. I’m trying to do a chamfer type pocket with a bowl bit.

What post-processor are you using?

Upload the .nc file?

I’m using a post that Julien modified for me. But that was a few years ago.

RADIUS POCKET.NC (2.7 KB)

The file starts off as:

%

(SHAPEOKO.ASC 23/05/21)

( ******* PART SETUP INFO ******* )

( ******* TOOL SETUP DATA ******* )

(BOWL BIT)

( ******** PART PROGRAM ********* )

N0002 G53G0Z-5.00

T02 M06 (BOWL BIT)

G00 G90 X0 Y0 S10000 M03

G43 H02 Z3.175 M08

Z2.0

G01 Z-1.0 F50.0

I believe the problem is that you have G00 separated from Z2.0 — change those lines to instead be:

G90 X0 Y0 S10000 M03

G43 H02 Z3.175 M08

G00 Z2.0

but that’s only a guess.

H02 isn’t supported, so I’d suggest taking it out, and G43 is ignored, so might as well leave that out, same for M08

that would make sense. I’ve run other basic code with the H02 and it ignored it.

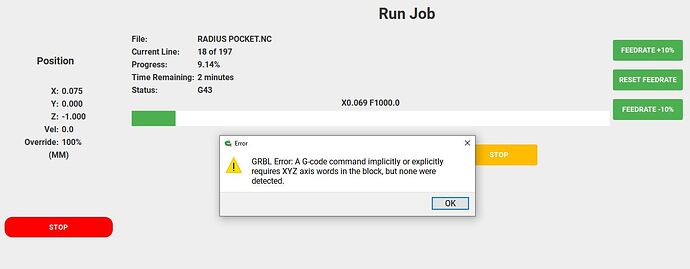

edit: adding the G00 didn’t change anything. Same error ![]()

18X12 CUTTING BOARD.NC (6.3 KB)

Here is a g-code that works.

I can’t see a meaningful difference between the two files, so hopefully someone else will be able to find something.

It’s not the I and J? Will carbide motion accept that?

Yes, Carbide Motion accepts G2/G3 arcs w/ I/J coordinates (and Grbl is quite forgiving of how these are calculated) — usually if this is a problem it’s an arc endpoint error.

If you look at the currently displayed line on your run screen “X0.069 F1000.0”,

the next line is “G02 I-0.069 J0”. G02 with no XY or Z. Some controllers will see this as a full circle.

Looks like it should be G02 X0.069 Y0.0 I-0.069 J0

When i make those changes I know get an arc endpoint error

Interesting. Maybe it doesn’t like full circles. Try semi-circles

X0.069 Y0.0 F1000.0

G02 X-0.069 Y0.0 I-0.069 J0

G02 X0.069 Y0.0 I0.069 J0

Or quadrants

X0.069 Y0.0 F1000.0

G02 X0.0 Y-0.069 I-0.069 J0

G02 X-0.069 Y0.0 I0.0 J0.069

G02 X0 Y0.069 I0.069 J0

G02 X0.069 Y0.0 I0 J-0.069

I think I’m going to try just a basic circle path and see what that gives. I’m not very familiar with all the milling features as I use Esprit for wire EDM

It just might be a parameter that I’m not using correctly.

Thanks for your help.

I’ve been playing around with my post. As I’m not at home to test the code does it look right to you? I changed the post so that it outputs I and J values. Normally it will ues R. Will the shapeoko reconcise an R value?

%

(SHAPEOKO.ASC 23/05/21)

( ******** PART PROGRAM ********* )

N0066 G53G0Z-5.00

T66 M06

G00 G90 X0 Y0 S18000 M03

G43 Z2.0

Z5.0

G01 Y-5.0 F1000.0

Z-5.0 F90.0

X10.0 F1000.0

G03 X15.0 Y0 I0 J5.0

I-15.0 J0

X10.0 Y5.0 I-5.0 J0

G01 X0

Z5.0 F90.0

Y0 F1000.0

Z5.0

G91 G28 Z0 M05

G28 Y0

G90 M30

%

GRBL will accept R values for circles, but IJ(K) is recommended.

%

(SHAPEOKO.ASC 23/05/21)

( ******** PART PROGRAM ********* )

N0066 G53G0Z-5.00

T66 M06

G00 G90 X0 Y0 S18000 M03

G43 Z2.0 (G43 not recognized. Ignored)

Z5.0 (Moving up from Z2.0 ??)

G01 Y-5.0 F1000.0

Z-5.0 F90.0

X10.0 F1000.0

G03 X15.0 Y0 I0 J5.0

I-15.0 J0 (What does this block do?)

X10.0 Y5.0 I-5.0 J0

G01 X0

Z5.0 F90.0

Y0 F1000.0

Z5.0 (Redundant. Z already at 5.0)

G91 G28 Z0 M05 (G91 [incremental] Z0 doesn’t move the tool. G28 should rapid XYZ to the G28.1 stored position.)

G28 Y0 (This would rapid back to Y0, then back to G28 position…???)

G90 M30

%

Try

%

(SHAPEOKO.ASC 23/05/21)

( ******** PART PROGRAM ********* )

G53G0Z-5.00

T66 M06

G00 G90 X0 Y0 S18000 M03

Z5.0

G01 Y-5.0 F1000.0

Z-5.0 F90.0

X10.0 F1000.0

G03 X15.0 Y0 I0 J5.0

X10.0 Y5.0 I-5.0 J0

G01 X0

Z5.0 F90.0

Y0 F1000.0

G28 M05

G90 M30

%

The Z 2. then Z 5 is because in my tool def I had initial clearance set to 2, Then in clearance tabs I had it set to 5. That’s my error

I’ll modify the post so that it doesn’t post the G43.

My biggest problem is that the g-code is only producing a semi circle instead of a full circle. I need to dig further into the post, which I’m not 100% sure of what I’m doing.

Did you want it to cut to the right, do 1 1/2 circles, then cut to the left?

That would explain the

G03 X15.0 Y0 I0 J5.0

I-15.0 J0 (What does this block do?)

X10.0 Y5.0 I-5.0 J0

Some controllers would see the lone IJ as a block to cut a complete circle. I don’t think GRBL intreprets it this way.

As I said, I’m still learning the milling features within esprit. If I make my lead-in/out a distance rather than an radiused entry it will output a full circle. I also made the post changes you suggested to remove the unnecessary code. Thanks for that. I will try this code when I get home. Thanks again for your help.

my g-code

%

(SHAPEOKO.ASC 23/05/21)

( ******** PART PROGRAM ********* )

N0066 G53G0Z-5.00

T66 M06

G00 G90 X0 Y0 S18000 M03

G00 Z5.0

G01 Z-5.0 F90.0

G01 X15.0 F1000.0

G03 I-15.0 J0

G01 X0 F1000.0

G01 Z5.0 F90.0

G28 M05

G90 M30

%

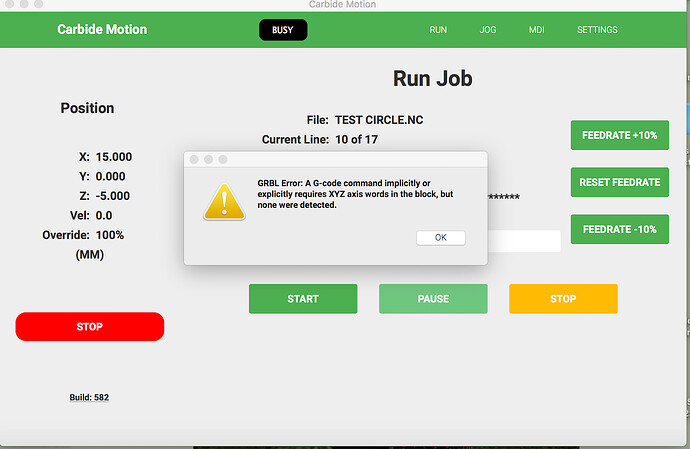

the error code

it does move to the correct Z and X position. I’m stumped!!

It doesn’t like this line with no axis words.

G03 X15 Y0 I-15.0 J0

Pretty much what we did above with different numbers. It gave the Arc End error.

Is there a way to tell Esprit to output linear motion only? (Convert circles to linear with a tolerance?)