So I do alot of fiberglass work, mostly in the custom motorcycle department. I’ve been using my Shapeoko 4 XXL more and more recently to help build my plugs. MDF is generally my wood of choice for machining for this. So rule of thumb use mdf to make a plug, coat with a special primer, make mold from plug, make part from mold. I’ve got a project I’d like to cut the middle man out and machine my mold and skip the plug. so here’s the deal, on my 3D adaptive clearing roughing pass its a 96 hour cut using a 1/4" square bit, running at about 1800mm/min. I need to cut 2.75" deep as well. Any ideas on how I can drastically speed this up? 8 inch diameter endmill bit? ![]()

What is the material for the mold? Can you use a larger tool with a 1/4" shank?

CC doesn’t have adaptive roughing, so I assume you are using another software?

Adaptive roughing still has a lot of non-cut motion, although it’s usually doing it pretty fast.

A cutter designed for roughing, and a toolpath that keeps the cutter engaged more would help.

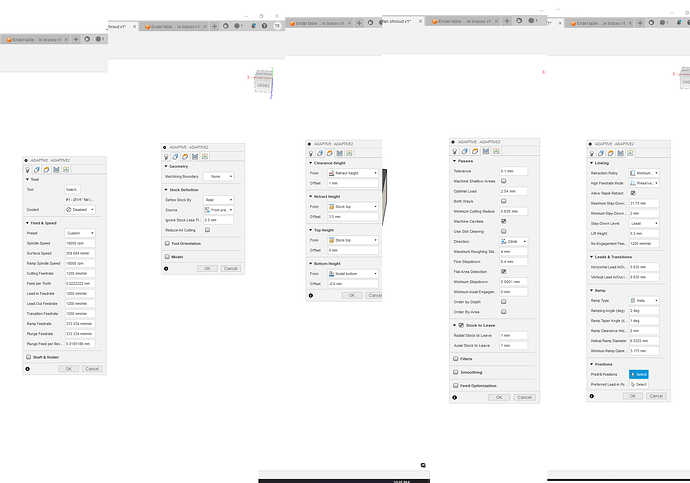

“3D Adaptive” indicates you’re using Fusion 360. Can you post a screen grab of all of your toolpath settings?

Material is MDF.

I could definitely use a larger tool altho I’d be concerned with killing my Carbide 3D router. I don’t seem to be having the best of luck with them.

Normally adaptive roughing does have alot of non-cut motion but for this one, (in the grand scheme of things), is a very low percentage. The biggest problem is, imagine making a 27X33X2.75 block of mdf disappear into dust using a 1/4" bit lol.

And I’m using fusion360.

And I said in my initial post I generally run at 1800mm/min in MDF I misspoke, thats for finishing passes, when clearing I stay around 1200mm/min.

A killer for speed with F360 is rapid speeds which are restricted for non paid versions. Try for a trial paid version of f360 or try something vcarve on an imported 3d model from f360.

I put an old shorty sock over my router intake to help catch dust before it went inside. I also blow it out every three weeks when I check and lube my machine. The sock does not limit the air flow, so no heating issues.

Every little bit helps

In MDF, if be running max RPM (24,000 if I remember the router max) and doubling that feed rate. I’d also likely be doubling the stepover. Also check “Both Ways” and that should halve the time the machine is cutting air for movements. That alone might half your time. Try that first. Then keep your feedrate and use the Feed Override in Carbide Motion to see if the machine likes more feedrate. You should be able to hammer thru MDF with that emdmill.

Your minimum stepdown is really small. Maybe change that to something much higher. If your are trying to get high detail a parallel pass with a ballnose is much more efficient than a detailed adaptive.

Your feed rate is slow. Maybe run some tests to see how fast your machine can cut. But I think you might be cutting your tool’s life short at low feed rates.

You can increase your helix angle to something like 5-10 degrees. That can cut a little time each time it does a helix.

The sock is an excellent idea, yes ever little bit helps!

Crap! I often do run it on both was and this time totally forgot. I did learn something tho, on adaptive stepover isn’t called stepover so I never adjusted it. I never caught on optimal load is technically stepover. Those 2 changes, and a couple small tweaks of my own now has it down to 26 min. I’ve run up to 150% using the feedrate override before on clears using 1200mm/min in toolpaths. Anything more or deeper of a stepdown than I feel like I’m killing the router. And thats with router on 5, not sure what RPM that equates to. Thanks for the info!

I’ve run 1800mm/min at a 4 inch stepdown and a 4mm stepover before, but anything more than that and it feels I’m being to harsh on the router. I had one router that only lasted a few hours of run time and bearings squalled and it locked up. The router I replaced it with I had to replace the brushes at prolly the 100 hour mark, and just maybe 24 hours into those new brushes this router stared squalling like bearings are coming out but at least it finished my file and didn’t die. I’ll swap it out for another new router tomorrow. I’m not even sure of life expectancy of these routers, but I’d think it should be more than that.

This topic was automatically closed after 30 days. New replies are no longer allowed.