Thanks Mr mingle for bringing up this subject

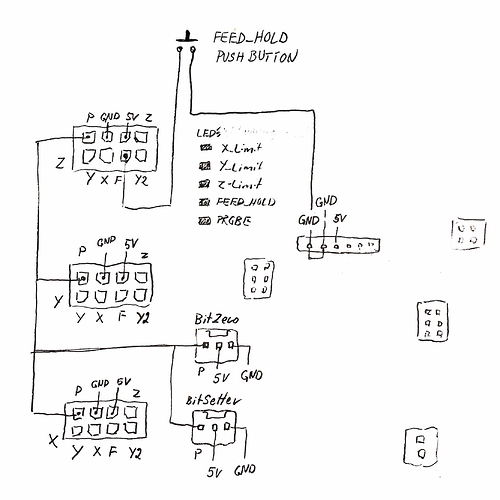

Multimeter says that the F signal is present on all X, Y, Z sensor input connectors. All signals seems to be mirrored on all connector and the individual wiring from each limit switch are using different pins except the Probe signal marked “P”. This is used both by the BitZero and the BitSetter.

This gave me a hint that if I ever, in the last minute, saw that I’ve forgot to attach grounding clip to the mill and probing sequence had started, then I could always interrupt the sequence by pushing the Bitsetter button. Especially as first pass is for Z-axis. This knowledge has saved me a few times lately.

This connection scheme indicate that magnetic limit switches might be wired as open collector and that it´s possible to add limit switches in both ends in the future. I am actually a bit surprised that there is no checkbox in carbide motion to make a kind of feed_stop during run if the CNC is trying to move outside the physical workspace.

FEED_HOLD is a “must” - and this is now tested on my Pro. It works  I haven´t had time to test it throughly yet, but I think there might be some minor bugs if being used during in some stages of initialization procedure or in Probe mode. Need to check more.

I haven´t had time to test it throughly yet, but I think there might be some minor bugs if being used during in some stages of initialization procedure or in Probe mode. Need to check more.

Anyone having a clue about the Y2 signal?

My notes attached as I would really prefered to have this information first day myself. Board version 3.0b