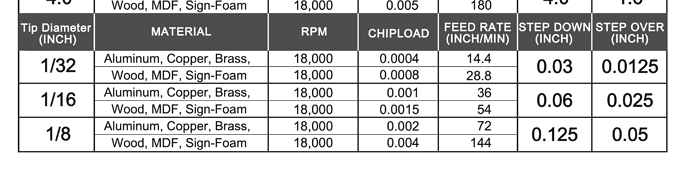

SO I’m adding tapered ball bits and ball nose bits and looking at recommended feed rates for the spetool website, I see rates of 144 INCHES/min. Is that normal? That seems outrageously high.

For hardwood, on these machines, that’s probably a bit too high. For sign-foam you could probably even go faster if the machine will take it without moving when it changes directions.

I have added several custom tools and when I went to the OEM sites they were recommending fantastic speeds. You can use the C3D ball bits as a starting point. The tapered bits are not directly supported as yet so others have recommended telling the custom tool data base the tapered bit is a straight bit. Since the 1/8 ball nose #101 is already in the database use those parameters to start. The #111 1/16" ball nose is also there. The #121 is also in the database.

The problem with OEM sites they are likely putting up F&S for industrial CNC machines and not hobby machines.

Since these bits are in multiple materials in the C3D database make a custom tool for each material.

Published numbers often assume industrial level machines which can run higher feed rates which is generally what you want in that environment where time=money.

The number to really pay attention to is chipload which is a function of feed rate and RPM (and the number of flutes). This translates more closely to the size of the chips you will make. Larger chips carry heat away from the cutter better than dust which is what you want since heat is the enemy of tooling. If you want to use a lower feed rate, a lower RPM will give you the same chip load. If you do a search on chip load calculator, there’s several useful online tools available. What I like to do is start out at the low end of the chipload spec and increase my feed rate on the fly to evaluate how well my machine is handling it.

This topic was automatically closed after 30 days. New replies are no longer allowed.