After my S5Pro 4x4 was delivered way early (great work distribution team!) and sadly sat in the shop for months due to lack of time and space, I have finally finished my first CNC project ever. In about 7 days I went from a machine in boxes to a completed project with a HUGE learning curve along the way.

My wife runs our church’s vacation bible school for the pre-k kids and asked for a massive 5 foot tall monstrance! I of course happily agreed to this ridiculous, I mean reasonable, request as these types of projects were part of the selling point and how I got it approved by the chief financial officer! I was up late all week getting it done but the reaction from the kids and church/school staff made it all worth it. While this was not the ideal first project, the time line and requirement for tiling meant I learned a whole lot in a short period.

Table and machine assembled, ready to go live! (I did do a few basic cuts to test functionality prior)

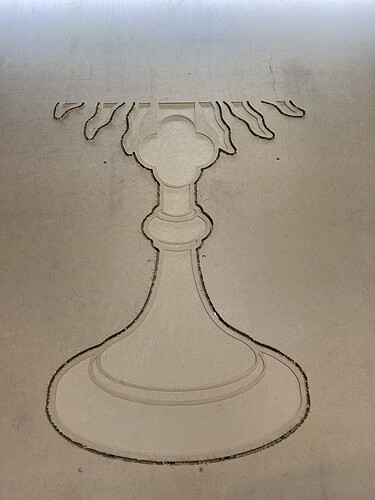

12" Mock up with scrap 3/4" MDF - Always test first! I ended up making design changes so this was well worth it.

First half done, now for the scariest part of the whole operation - Moving the piece for tile section 2…

Layout prep paid off! The cuts lined up almost flawless.

Time for minor clean up work and paint, one helper for scale.

Finished project

Thanks to everyone at the Carbide 3D team for putting out an amazing product and the community for tons of videos and topics for new guys to learn from. I am especially tankful for Nicholas Meastas who I had the chance to chat with afterwards and get my laundry list of questions answered. I look forward to creating many more things and seeing what else I can do with my favorite new shop tool.