I acquired my SOP just over a year ago. The first year, being a new CNC user, I familiarized myself with the machine by doing small projects such as various boxes/cases, Astek calendar style of StarWar and others. In the fall I designed and made my base for my CNC. My new Shapeoko base cabinet with vertical mounting - #15 by Bobster

On the software side, several years ago I occasionally used Sketchup for carpentry projects and then for 3d printers. Then I switched to the software Fusion 360, free version for hobbyists for my 3dprinting. For the CNC I did my first projects with Carbide Create then depending of the kind of projects I used also Fusion360.

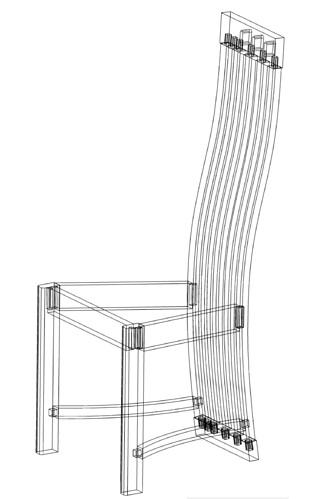

After about ten month, having added a water cool spindle and required installation, I decided to undertake a more complex project (at least for me), I wanted to add 2 chairs to my dining room set which is decades old (25~30 years old). Here is a photo of the model. Note that the side rails and bottom rungs are at compound angles.

My first challenge was to design the chair with Fusion360, I was not very familiar with the software, only used it for small projects for the 3d printer and some of my small CNC projects. The learning curve was a little, a lot difficult with many religious words! But I got there and I learned a lot. At almost 70, memory doesn’t work as well! Here are the pictures of the drawings of the chair.

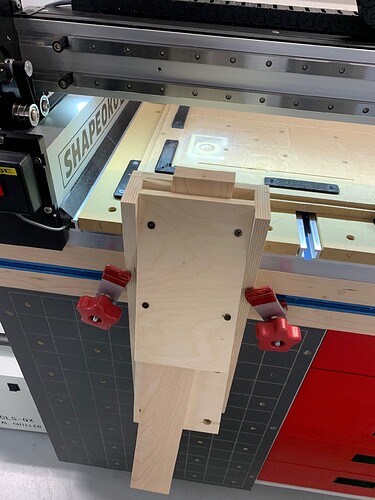

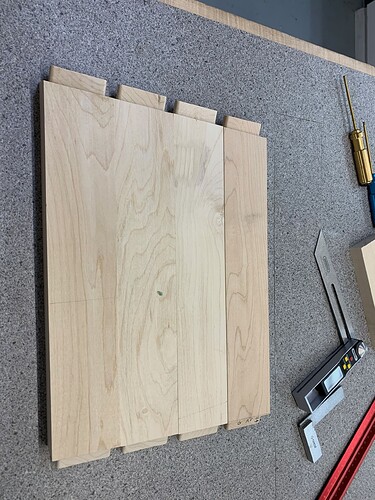

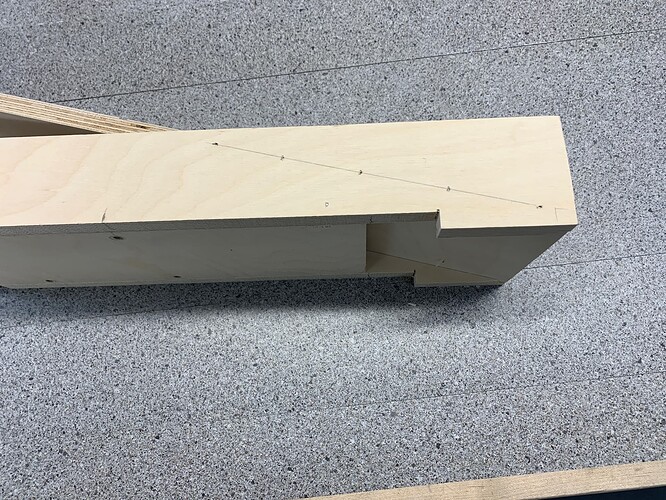

I started by making the vertical parts of the backrest. I need 6 identical pieces per chair, for a total of 12. Wisdom comes with age, I made 14 which was a good thing. Two 4-pieces boards and two three-piece boards. Since the SOP has around 34" by 34" working area, I had to cut my parts diagonally across the table. Here is a board with three cut pieces. The demarcations at each end mark the beginning where the tenons will be.

By removing the pieces from one of the boards which contained 4 of them, one of the pieces came out crooked and twisted! There was a lot of tension in the wood…

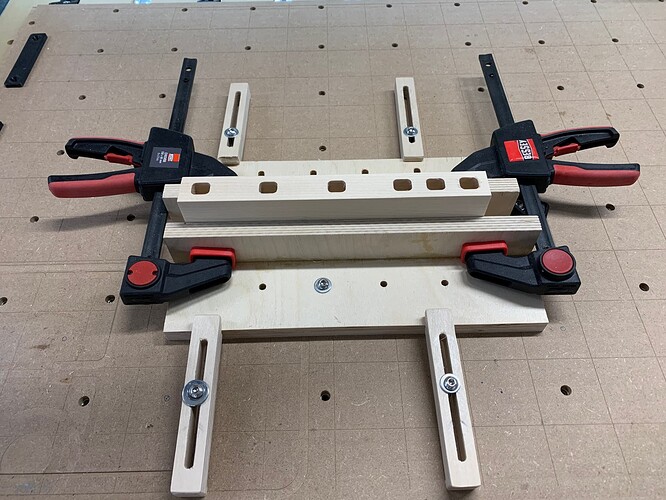

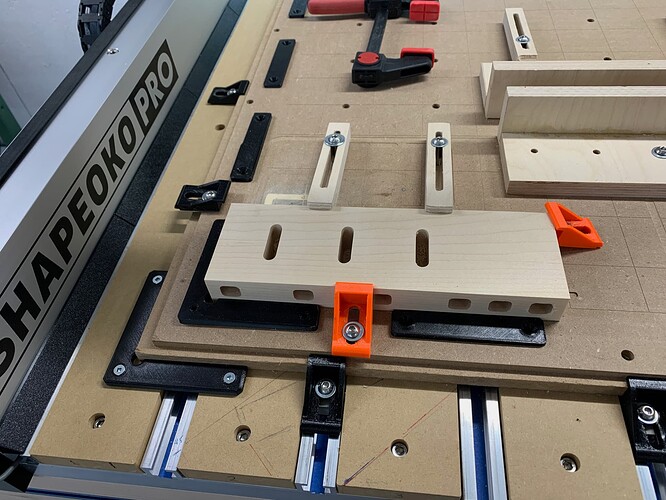

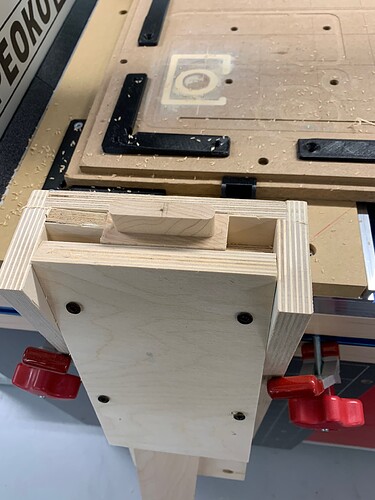

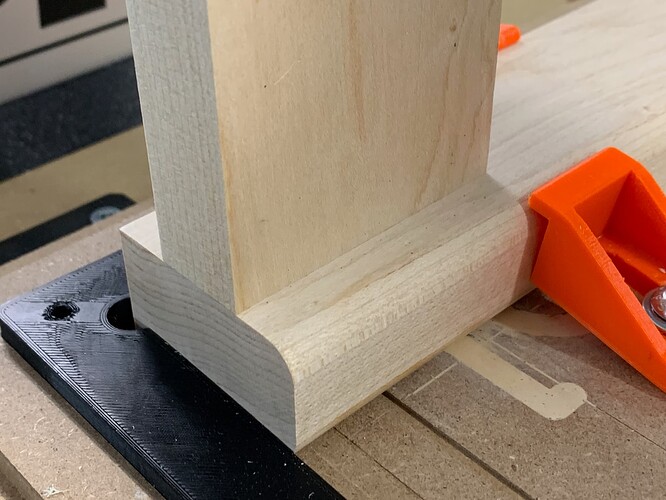

To make the tenons on the parts of the backrest, I made with Fusion360 and the CNC a template for putting the parts vertically at the front of the CNC. One template for the bottom and one for the top. It makes nice tenons.

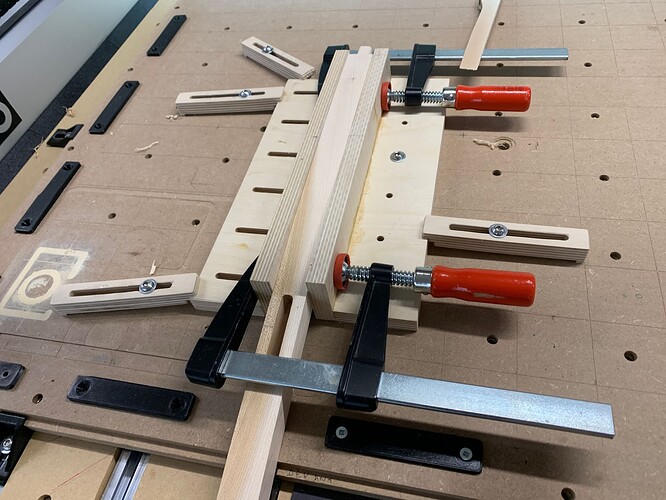

Next step is easy, the top and bottom piece of backrest. I make the mortises after the tenons, it allows to adjust the mortises to the tenon without moving the part on the CNC table. It’s very simple to remove an extra 0.1 mm from the mortises with the software and go back to the CNC.

Here is the backrest without the roundings of the edges:

Now the side aprons below the seat. These are compound angles, but the two ends of the aprons are parallel, which simplifies the template a bit. By alternating the two screwed pieces with angles parts, you can make the left and right side.

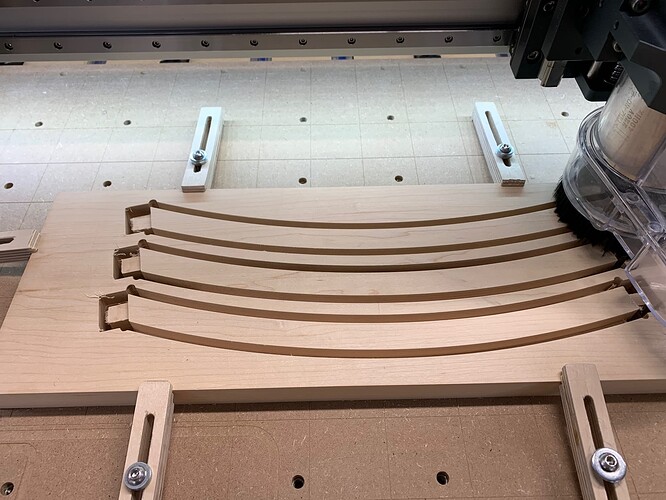

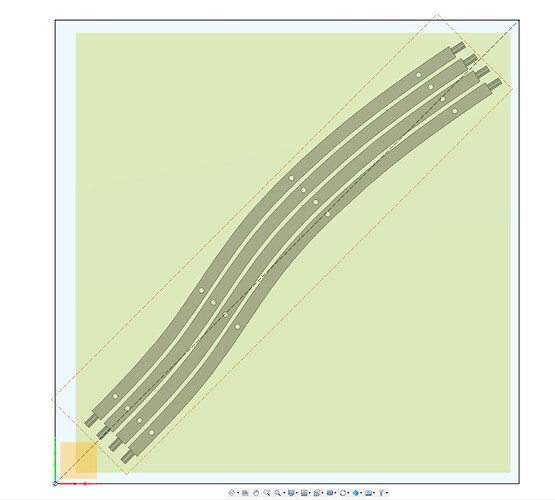

Now the stretchers, pieces also at compound angles, the ends are not parallel and in addition the pieces are curved! I didn’t want to take the previous method of the template. It would have worked, but requiring several complex jigs… I decided to make them mostly with the CNC and finish with a wood chisel, which I don’t have much experience and dexterity… With straight bits, the CNC cannot do negative slopes but can do positive slopes by going in small increments. The approach I’ve taken is to carve the sides of the stretchers up to 3mm from the bottom, carve whatever the CNC can carve for the tenons in steps of 0.5mm down to the bottom of the board. Then I reversed the piece from top to bottom (using indexing pins) to reach the corners of the tenons that became accessible. Finally I finished the size of the sides of the stretchers, leaving a few tabs. There are only small parts with negative angles below the tenons to finish with a chisel. It is also necessary to correct with chisel the curvatures left by the 1/8" bits in the corners of the tenons.

The most difficult being finished, I then milled the mortises in the parts of the backrest. I put the section to be drilled parallel to the table and calibrated the CNC to make mortises centred on the desired point.

The tenons of the front apron are very simple and here is what it looks like without touching up or sanding with a brand new bit:

and the “fit” with the mortise is perfect:

If you’ve read this far you can guess that front leg mortises are very simple to make.

The rounding of the backrest and the legs were made on the router table with a 1/4" round over bit.

Here is the final result, there remains the sanding, the gluing and of course the finish. The reinforcement parts are still missing.

I must say that my SOP is my favorite tool in my shop!