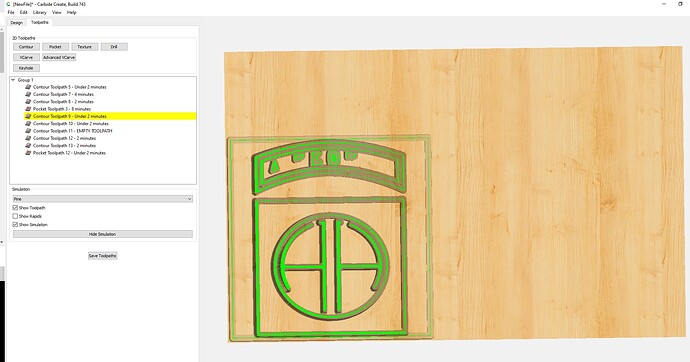

Hello everyone, I am starting my first project on the Shapeoko CNC. I am new to the CNC world and successfully completed my “Hello World” test yesterday. I am currently working on my first project- coasters. I have been watching videos on youtube, and using Carbide’s coaster project intro (Coaster Project - Carbide 3D). I am currently having an issue. On my project, I am trying to replicate the 82nd Airborne Division Patch. When I attempt to pocket the AIRBORNE letters, they become distorted or do not populate. Has anyone seen this issue, or have any tips for recommendation? I have provided a screen shot for reference.

If possible, uploading the project file in the future will help us see what is going on.

In your case, I would guess that the bit you want to use is simply too big for the letters, and so is skipping all the areas that it doesn’t fit. This kind of case is perfect for doing a VCarve.

Likely the tool selected is too large for the toolpath. Try using a smaller tool. If a vee cut then try a 15 degree vee bit. As @mhotchin post your file for more help.

Thanks for the reply. I have attached the file. I am still trying to learn how bits and cuts work.

Can someone please explain a V Carve? From the provided Carbide text I understood the following:

There are 4 types of toolpaths to choose from:

- Inside Cut - puts the cutter on the inside of the feature

- Outside Cut - puts the cutter on the outside of the feature

- Pocket - clears everything INSIDE of the feature selected.

- No Offset - cuts directly on the line

Can you point me to a reference for proper bits and sizing? I have been looking at bits from Lowes and Harbor Freight. I am open to suggestions and brands.

82D ABN Coasters.c2d (128 KB)

A VCarve uses (not surprisingly) a V bit. The thing about V bits is that depending on how deep they run, the path they carve can be wider or narrower.

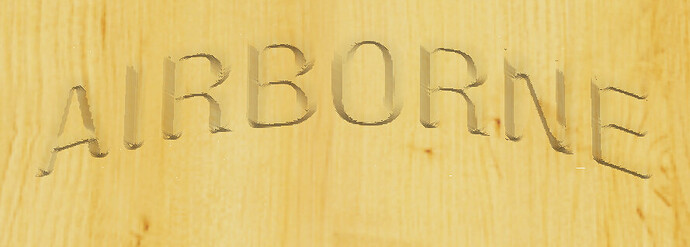

So, a VCarve uses a V bit, and as it runs it moves up and down in height so that the bit touches the vector on both sides. Using a 60 Deg V bit, the lettering would look like this:

A 60 deg bit is a pretty good first V Bit. For really thin letters you’d use a narrower bit.

The one thing about a VCarve is that it is very sensitive to the height of the surface of your stock. If it’s not perfectly flat and constant thickness, the lettering will be distorted.

Here’s your file with the V Carve path added - it’s at the bottom of the list of toolpaths. I disabled your toolpaths so the simulation would show just the letters. Also, I grouped all the letters together into one object, so it’s easier to select.

82D ABN Coasters.c2d (120 KB)

Mike, thanks for the help. I am going to try and cut out the coaster this weekend. I will post pictures to show a finished product.

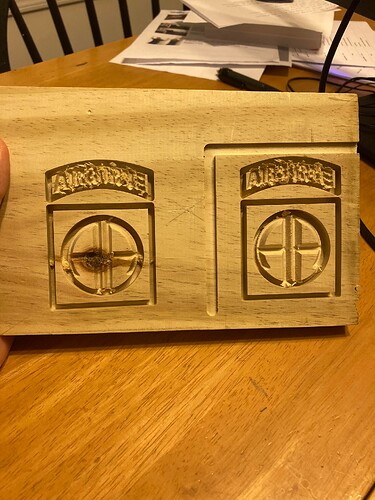

Gentlemen, thanks for the assistance. I attempted my first project tonight. I had an issue with zeroing my machine to the center of the wood I was using. I wrote to the help line and was informed I should try and zero to the corner. At first, I was successful; however, as the project progressed I ran into issues. I noticed the endmill started too far to the right. Once the design progressed, it ended up cutting past the designated area, and broke a piece of my working hold kit. I also realized that the “AIRBORNE” cut ended up not being distinguishable. I think that may be due to their proximity and the 60 degree end mill I used. I will have to experiment with that. Any recommendations or has anyone experienced these problems before? I am setting up a video appointment with the Shapeoko personnel to help with the failed jogging and zero.

The file I used is attached as well.

82D Coasters.c2d (132 KB)

What machine do you have? That can help us help you, also as for the airborne section I think the 60 degree is too big (width and depth) for your letters I use a 30 degree spade bit for close letters like that.

I have a Shapeoko 4 XXL. I would agree the 60 degree bit was too much.

I would say check the eccentric nuts on your z plus, where it connects to your x rail, seems like your slipping and losing steps, could be loose or could be too aggressive of cuts causing missed steps. But your on the right path use the support and video walk throughs and you will be giving us advice soon!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.