Hi all, I though I’d chime in a say hello. I received my Shapeoko 3 XL a little over a month ago and haven’t had a lot of time to work on it, but it’s setup and ready to go when I can. I’m so impressed at the packaging, even the UPS driver didn’t realize how heavy it would be and was impressed with the Made in the USA labeling and thickness of the cardboard. UPS can make a square box into a ball pretty quickly with most items, not the Shapeoko however! Thank you Carbide3D!

I setup my Shapeoko on the floor in my office where I could test it and update GRBL. I’ve since moved it to my old office in the next room over, where I hooked it up to a Raspberry Pi 2 with CNCJS to control it. With this setup I can design on my main system, then open the CNCJS bwoser window and upload the G-Code file. Then I walk to the other room and, using an old laptop, I open the browser window pointing to the Raspberry Pi with CNCJS and click Refresh. The G-Code I loaded on my main system shows up in the laptop browser where I can Zero out and setup the Shapeoko to run the file.

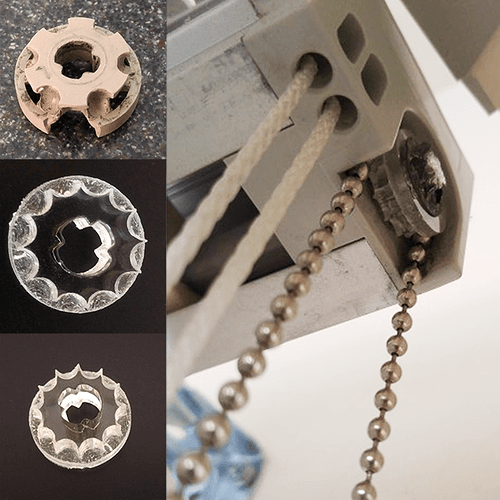

One of my first, and probably most useful jobs, was for something that’s been bugging my family and I for several years… The vertical blinds for our patio door. Every time the chain was pulled to rotate them open or closed it would skip and loose position. The end of the chain was almost to the top of the mechanism and out of reach of everyone but me. It turns out it was a broken plastic gear that the chain beads rest in and when the chain is pulled the gear is rotated, causing the blind slats to rotate. I searched for a gear but everything I found wanted me to but new blinds or a whole new mechanism. I first tried making up a two piece part in Adobe Illustrator and then cut it on my laser, but that never worked. When I got my Shapeoko I realized this was a perfect task for it. I took my designs from Adobe Illustrator and brought them into Fusion 360. After a little extruding to match the original gear as closely as possible I setup the CAM job with milling and cutting. I sent the job to CNCJS and then on to the Shapeoko. I used .25" Acrylic from Home Depot for this project and milled it with a .125" spiral endmill. The gear installed perfectly the first time and has made my family happy and fixed our vertical blinds. I didn’t do anything for the slight roughness of the gear since the chain beads rubbing against it have smoothed it out nicely since I installed it. It actually feels like new again.

Cheers,

Jeff