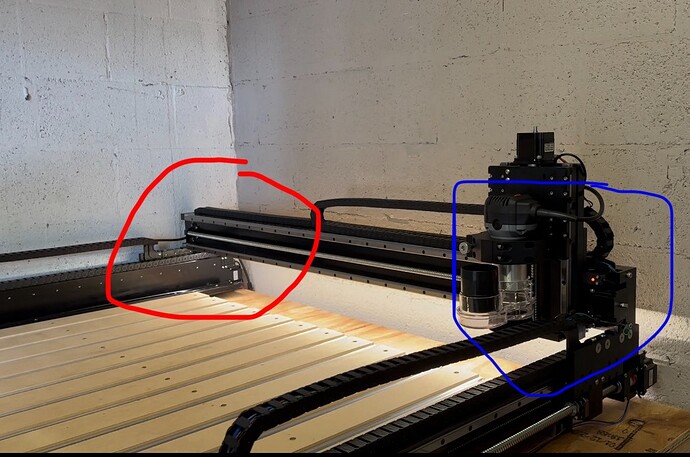

I just installed my Shapeoko 5 Pro and on the Y axis or the left hand side. In the photo circled red that side arrives at the end after the circled in blue arrives at the end. I was getting a code, but after a couple times it stopped giving me the codes. When I make the machine move forward The part circled red looks like it gets stuck and makes a sound and it stops after it continues to move forward. I wish I can put the videos I took so it’s easier to explain that’s been happening with me. The code was HM010 but again it stopped after I did I did the Initialization a couple times

You could have one or several things going on to cause this problem Give Support an email and they should be able to walk you through the trouble shooting process. While you are waiting you should also check all your connections and run through the setup process again just to make sure you didnt miss anything.

Anthony

Could be that your table is out of square. Measure cross corner to check. Even a small amount will add up over distance. You may need to loosen all table parts to get it right then go piece by piece to retighten everything back up, continuously rechecking for squareness. Yes, it is tedious. Yes, you only need do it once. Chances are good that the gantry itself is square. Limit switch is on the right side so if the left is leading, that will hit first.

Once you’re good, the real fun begins. Keep at it!

Where do I measure exactly if you have a picture I went to the warehouse and measured it not sure if I had it right but one side was 75in and the other was I think 75 1/2in or 75 3/4in

If you did as @HaroldO said (back corner left to front corner right then back corner right to left corner front) and your measurement is 75 and 75.750 you are not square.

I think the best way is to remove your slats and loosen the plates the slats sit on. Square your machine. If you need to, use a belt or rope to keep pressure on it while you tighten the bolts and install the slats again.

Good Luck.

Yes, measure from the back left corner to right front corner, across the table.

Then do the same from back right to front left. In short, forming an X across the table.

Since you are mismatched, I suggest loosening the base parts then moving one side slightly until the cross measurements are exactly the same. Then tighten everything back up, being careful not to move anything in the process and measuring a few times along the way. This should solve your trouble.

My CNC is screwed down to a work table. So I was able to secure one side then move the other to square and screw it down. Then the remaining parts were easier to get done without messing myself up. Your machine looks good in the picture so you obviously are handy with tools. Good luck from here!

OK so far I think I fixed it. I think it was the gantry, I wasn’t there Since I was getting lunch for my uncle and father And they were the ones that did the gantry. What I think that happened they didn’t align the Gantry correctly. for the measurements 74 5/8in and The other side is 75 inches so far I did two Initialize and no codes has came up and the gantry hasn’t made that sound and they both arrive at the same time

Excellent! Now the real learning curve begins!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.