Working on a two sided PCB using FlatCam to generate the CNC code and Candle as the CNC controller. Having some trouble. When I run the code, the spindle spins up, but the machine doesn’t do anything. Any suggestions, tips, and settings thoughts would be greatly appreciated.

1. 7148B4636B_Copper_Signal_Top.gbr_iso_combined_cnc.nc (48.7 KB)

2.Alignment Drills_cnc.nc (1.4 KB)

3.7148B4636B_Copper_Signal_Bot.gbr_iso_combined_cnc_1.nc (37.1 KB)

4.7148B4636B.TXT_cnc.nc (3.1 KB)

5.7148B4636B_Copper_Signal_Bot.gbr_cutout_2_cnc.nc (3.1 KB)

Neither FlatCAM or Candle is supported by Carbide 3D. What machine are you using?

I am using the Nomad 3. It’s all open source and other users on the forum have used the same software, so I was hoping I might hear from them

Now that you’ve listed your machine, they’re more likely to chime in.

What is shown on the CM screen when it runs & stops? Here’s what I see in your Alignment Drills_cnc.nc file

G20 (English Units / Inches)

G90 (Absolute Coordinates)

G17 (XY Plane)

G94 (Feed per minute)

G01 F300.00 (Set the linear feed rate)

M5 (Spindle Off)

G00 Z15.0000 (Tool change position Z 15" ??? Your envelope is only 3", right?)

G00 X0.0000 Y0.0000 (Rapid to XY 0)

T1

(MSG, Change to Tool Dia = 0.0393 ||| Total drills for tool T1 = 4)

M0 (Stop for tool change)

G00 Z15.0000 (Rapid to Z 15" again??)

G01 F300.00 (Set linear feed rate again?)

M03 (Turn on the spindle, no speed? Manually set, right?)

G00 X-0.2500 Y0.0000 (Rapid to start position)

G01 Z-1.7000 (Feed to cut depth. -1.7" ??? Seems like a pretty deep hole for this machine)

G01 Z0 (Feed out of hole)

G00 Z2.0000 (Rapid to retract plane. again 2"?)

G00 X2.2500 Y0.0000 (Rapid to next hole)

Nothing happens. Machine spindle spins, z axis goes up, spindle keeps spinning but nothing else happens. Seems I have some errors in my CAM programming with flatcam

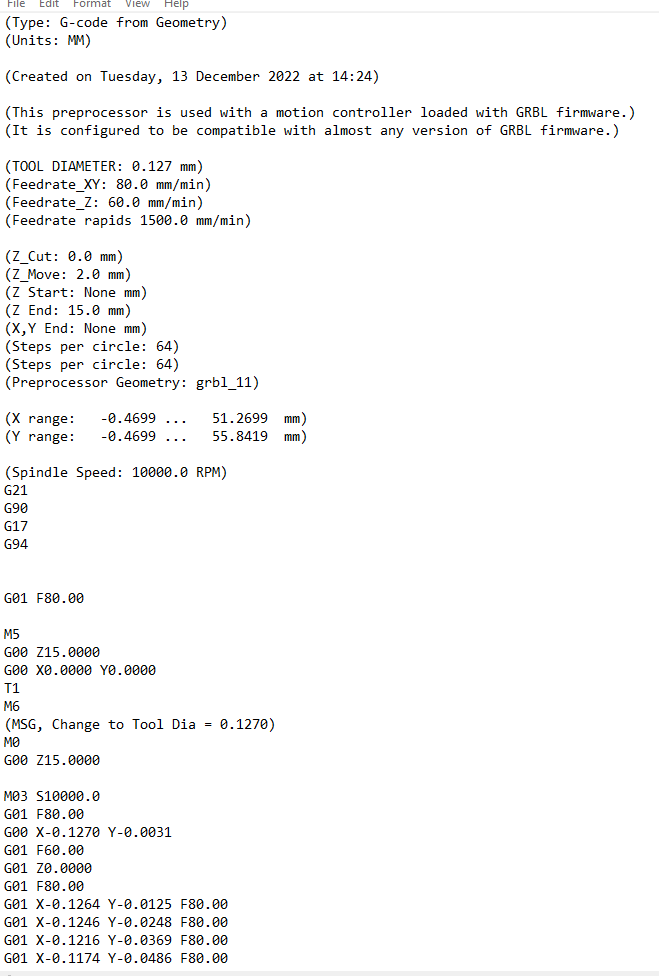

Tried generating the CAM again. How does this look? Is G01 F80 an acceptable command?

2. NEW7148B4636B_Copper_Signal_Top.gbr_iso_combined_cnc.nc (228.0 KB)

Not sure about GRBL. On Fanuc type controllers I think it’s OK. It just sets the feedrate at which linear/circular interpolation will occur. F is modal. On Siemens controllers I think it would throw an error with no movement. It is strange to see F set before feed motion occurs. i.e. there is a rapid right after that line?? If it’s freezing right after the spindle on (M03 S10000.0), that could very well be it. But it occurs about 12 lines up, before the M5 as well. I wouldn’t expect to see F until the G01 Z0.0000 line>

G01 Z0.0000 F60.0

I see you changed to metric (G21). So your tool change is at Z15 (mm above the zero). Although that shouldn’t stop the program, just make it harder to change the tool.

Try this:

G20

G90

G17

G94

M5

G00 G53 Z-0.25

G00 G53 X-4.0000 Y-7.000

T1 M6

(MSG, Change to Tool Dia = 0.0393 ||| Total drills for tool T1 = 4)

M0

M03 S10000.0

G00 X-0.2500 Y0.0000

G01 Z-1.7000 F60

G01 Z0

G00 Z2.0000

G00 X2.2500 Y0.0000

G01 Z-1.7000

G01 Z0

G00 Z2.0000

G00 X2.2500 Y2.1800

G01 Z-1.7000

G01 Z0

G00 Z2.0000

G00 X-0.2500 Y2.1800

G01 Z-1.7000

G01 Z0

G00 Z2.0000

M05

G00 G53 Z-0.25

M02

The M0 is a stop after the toolchange. You’ll need to hit Start to continue.

The G53 lines are in machine coordinates, not workpiece coordinates.

Think I’ve found the culprit. Didn’t realize Candle doesn’t support the M6 command for tool changes. Generating the files without the tool change seems to have resolved the issue. Thanks for your suggestions everyone!

Your first file didn’t have an M6…looks like that was intentional.

(Preprocessor Geometry: GRBL_11_no_M6)

This topic was automatically closed after 30 days. New replies are no longer allowed.