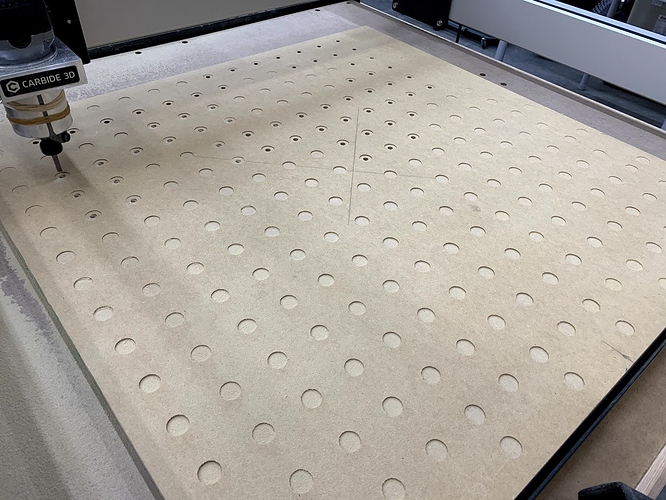

Is there an adjustment that I can try to level the bed of my XXL? I just set it up, squared it. Ran Hello Word ok and went straight to cutting this wasteboard. Right side and top left holes are not carving, front left looks a little too deep:

You can either try squaring up the machine, or you can machine the bed to be planar with the rails/gantry and then re-run the file.

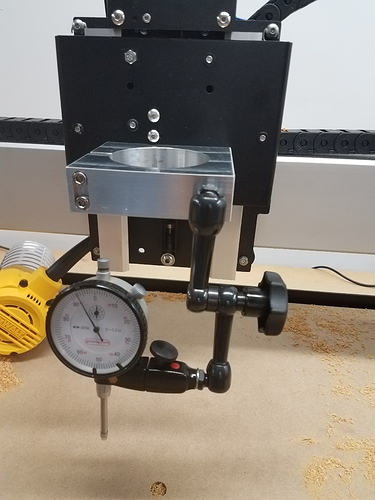

I drilled and tapped a hold on the spindle bracket so I could mount my Noga indicator arm and dial indicator.

Then I measured the board and used post-it notes as shims to make it flat

I cannot find my notes but am pretty sure I was able to get it flat to within a few thousands of an inch. Plenty good for the work I do.

I am way too lazy to spend the time to machine the surface flat.

I would shim the board to get it close to flat in relation to the machine when putting the holes in this side. This is going to be the bottom of your spill board, so it’s really not that critical. After you get all of your holes in and your inserts put in, flip the board over, and secure it. Then flatten the spoilboard with a 1" spoilboard bit. This will get your spoilboard nice and flat in relation to the machine.

One other note…You may want to shim under the center rail of your machine. There is some flex if you push down on the center of your board. Some people have used foam board under their machine to add extra support to the center. If you do this before you flatten the spoilboard, it may save you some headaches later.

great idea! thanks for sharing.

I found the 2 front left screws were not holding down the original wasteboard. The threads were full of paint and I thought they were tight, I broke the ball off of an allen key trying to get it tight! I finally got it somewhat flat/level, but the one screw is now stuck and not tight. thanks for all of the suggestions.

The ball end of a hex key should never be used for actually torqueing down a fastener — only for loosely getting it into position.

May need to use an EZ out or other screw/bolt removal tool.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.