Hello,

I purchased a Shapeoko 3 xxl with the new Z axis. Purchased a Amana Tool 45525 Carbide Tipped 1-1/8 Dia x 1/2 CH x 1/4 Shk x 1-19/32 Long Spoilboard Surfacing & Flattening 3-Flute Router Bit. But when I put the bit in my router, and lower the z axis, it doesn’t touch the board to zero out the z axis. I have installed the bit into my router with almost the whole shank exposed. And I know that is unsafe to use it that way. BTW, I am very new at CNC work, only had my machine for a couple of weeks and it could be used error but, Did I purchase the wrong bit?

You’ll want a supplemental wasteboard on top of the structural one.

Make one so you can face the entire surface.

Two possibilities…

First of all - you should have a spoilboard on top of the board that came with the machine… so it is easily replaced when it gets too chewed up… this will bring it 3/4” to 1” nearer the router.

Secondly the router should be clamped low down in the router mount.

Either of those two should explain why the bit cannot reach. It is very unlikely that you bought the wrong bit.

If the above does not address you problem, then I think a picture of what you have will be most helpful.

You can slightly increase the depth you can reach by installing the spindle adapter from the bottom of the spindle mount.

Doesn’t look like that will be enough though — I’d suggest surfacing with an endmill which will have sufficient reach — a #201 works, just requires a bit of patience.

Yeah, the file I got, I changed to the 201, it was going to take 5 hours to complete. I started it and I guess it got corrupt and started skipping a row of passes. The only option I see to use this bit, if it isn’t user error or machine error, is to put another MDF board in-between the stock table and my spoil board, which will raise the board up another 3/4 inch.

It doesn’t need that much patience — one can go quite quickly when making a skim pass to flatten a wasteboard — double or even quadruple the feed rate in CC, then use feed rate override to adjust in CM.

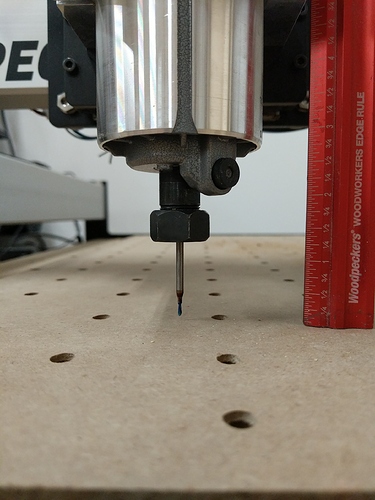

Hmm… so does this mean that the new Z-plus does not come down as far as the belt drive Z axis? You cannot reach a 1” supplemental spoilboard with a surfacing bit?

From the picture, it looks like you could not even flatten a 1/4” ( or perhaps a bit thicker) piece of stock with a surfacing bit?

Doesn’t that make a surfacing bit pretty much useless with a Z-plus… I use mine all the time to resurface spoilboards and fairly thin stock for accurate vcarving… or am I misinterpreting the Issue?

@WillAdams or @Luke please advise.

The bit in question either has a very short shank, or is choked up on more than is advisable.

So are you saying the z-plus does descend as far as the belt driven z axis? This is important to be clear about imho.

There will be no problem cutting through to the spoilboard with a standard 1/8” endmill which are a lot shorter than a 1/4” endmill? The whiteside 6210 surfacing bit will reach? I never considered that to have a short shank.

No, I purchased the Whiteside 6210 also and it doesn’t reach. The same results.

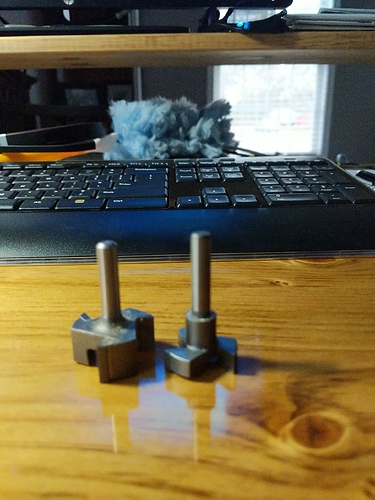

Amana 45525 on left, Whiteside 6210 on right.My whiteside 6210 with the belt driven z axis will go through a 1” supplemental spoilboard by at least 1/2” which is fine.

I am now really concerned about cutting down to the spoilboard with 1/8” endmills for full depth pockets or profile cuts. These also typically only have a 3/4 shank and a typical cut length of 1“. Will these work with the Z-plus?

I have a Amana 46237-k, 1/16th with 1/8 Shank, I can test and let you know. So you want me to cut down to the spoil board with it?

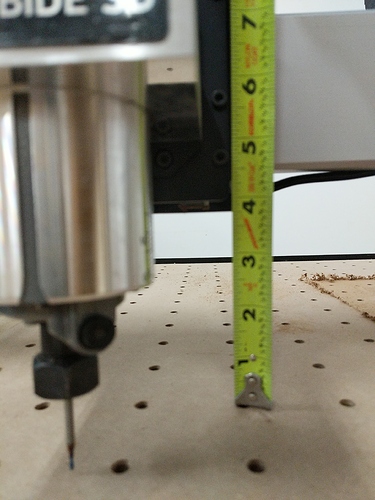

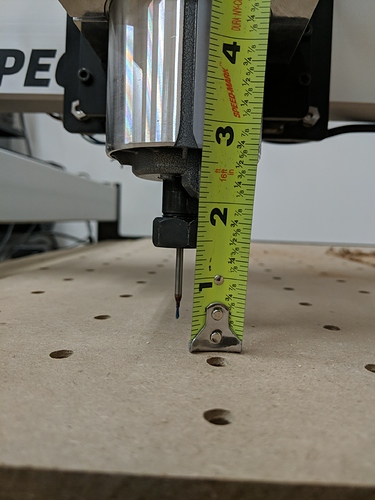

Yes you could do that… but just measuring from the bottom of the collet to the top of the wasteboard when full descended will be good. Better yet would be to measure from the bottom of the x-axis extrusion to the bottom of the collet… that would be definitive but more tricky to measure.

I have a 1/2” aluminum base board with a 1/2” spoilboard to maximize the z cutting depth. What is you baseboard and spoilboard thickness?

Another possibility is that the combined length of the Carbide3D router barrel to the bottom of the collet is shorter than the DeWalt router that I use. I just measured mine at 5.4”.

As I say - I have plenty of z-axis travel with the belt drive z axis… so I have never thought I would have any cutting depth problems until I saw your pictures with the z-plus. I was expecting to buy that upgrade when it became available…

My board is the standard baseboard that was shipped with the Shapeoko 3 xxl and my spoil board is 3/4" MDF. I can fix this by adding another 3/4" board on the baseboard, then putting the spoil board on top. This is my first CNC, so I don’t have plans on working on anything with depth (like boxes or real thick stock). I just wanted to check to make sure it wasn’t user error.

You certainly need more than 1/4” shank in the collet for safety and I would expect unacceptable runout with so little of the bit supported by the collet even if it was safe.

With my z-axis descended fully, the bottom of the collet touches the spoilboard even though my combined baseboard and spoliboard thickness is 1”. Yours must be thicker I assume your base board that come with the machine is either 3/4 or 1” thick.

@lcifers

If it were mine, I’d be looking for something that I assembled upside down.