Having issues with my flattening bit, it is 1 1/2 in in diameter. My workpiece is 8" x 8". I set my X,Y with a centering bit in the lower l/h corner, I install my flattening bit it will not cut to the edge, it will leave@ 1/4" material around\d the edges. What am I missing? I don’t get it… Thanks in advance for all your help.

If your material is 8" x 8" then you want to make your cutting area 9" x 9". That gives you a half inch over the edge to flatten the whole 8" x 8" material. The usual way is to make a pocket and that cuts from the center out. Some people like to draw a continuous line back and forth and do a contour with no offset.

When using such a big bit in a trim router you want to take very low depth of cuts and run at a high IPM to avoid burning the material. Trim routers are not really good at running a 1.5" bit because they are around 1.25 HP. A 1.5" bit puts a considerable load on a trim router. If you have a spindle that is different because they have more torque. Either a trim router or spindle you want to go fast. A 1.5" bit generates a considerable amount of heat due to the high engagement of the material.

So make our pocket all the way over the edge of the material to get the whole thing cut. Depending on your step over you want the last pass on each level of stock removal to be partly over the edge. Going up to the edge will leave rounded corners with stock material left on the corners.

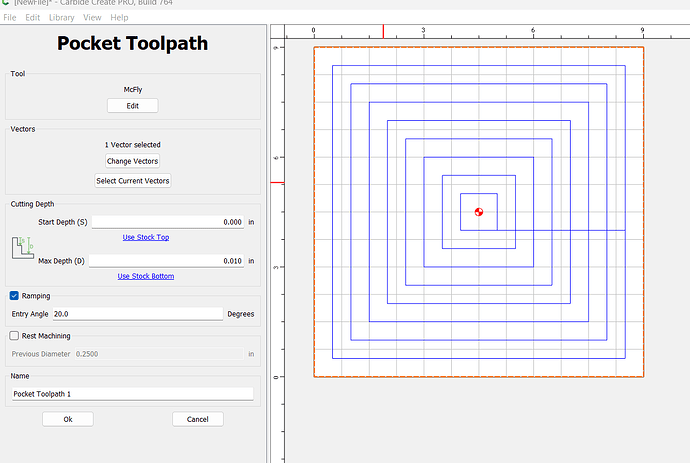

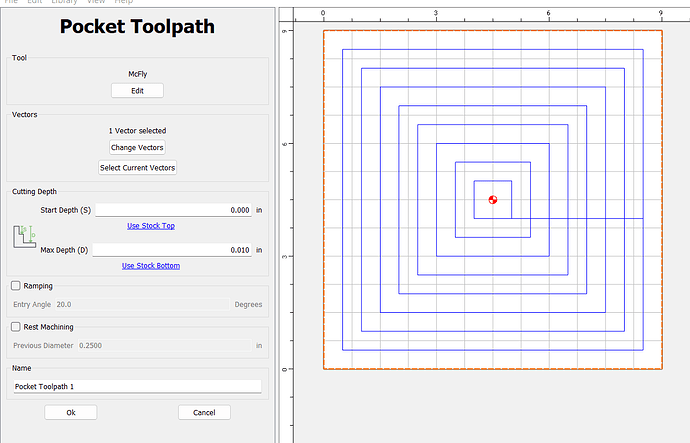

In the examples below I used the McFly (1") with 50% stepover and 0.010 depth of cut. Change the IPM to 80-120 IPM and if you have Pro CC ramping.

CC Pro with Ramping

CC Without Ramping

Guy, thankyou so much for the great information and your time. So I think I’ll buy a 1" Mcfly bit and with your instructions it should work out. I do have a spindle, they work so well. What rpm would you suggest to run that bit at?

Thanks again for your time, much appreciated!

Greg

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.