Hi everyone,

I hope you all enjoy the video. This process took me roughly a week to finish (not including CAD/CAM) time. There was a lot of testing prior machining on the real plate as I wanted to be fully comfortable. This includes testing dimensionaity and screw threads profile.

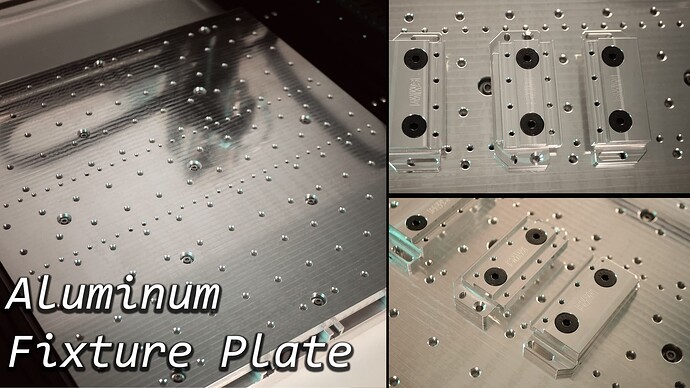

The plate is modelled with;

- 8mm dowel pins + M6 threads all in one hole.

-20mm spacing M6 Thread center to center for the SMW Vises

-13x mounting point to the frame of the cnc itself

-Chamfer on top of every hole surface for smoother touch and aesthetic

All of the holes are fully cutout to the other face to prevent chips being stuck onto the metal threads eliminating potential damage