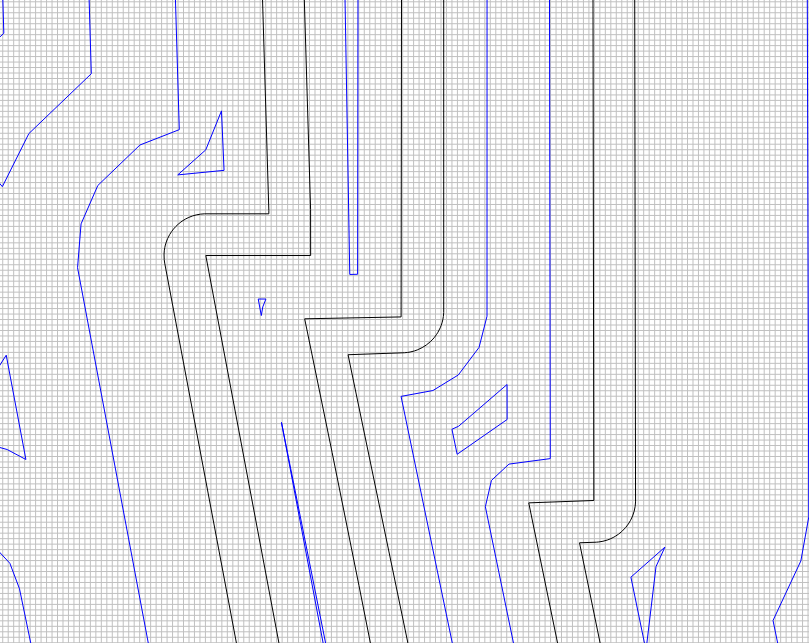

I’m trying to make a logo with channels to pour epoxy into. The actual carving will be into a layer of black epoxy. Basically I’m just making outlines. If you look at the simulation you’ll see on the right side of one of the outlines around the oil derrick, there’s 2 places where the CNC skips sots and makes a random circle. I’m very new, and would appreciate any help and advice.

Oilers Logo.c2d (872 KB)

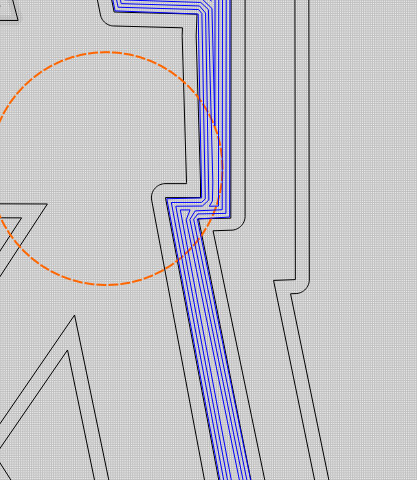

This spot the Vector is too narrow for the Bit.

I see you used a 1/16 bit. Change the toolpath into an V-Carve and use a 30degree v-bit that’ should work.

Here’s the same toolpath but using a 30degree V-bit

That looks good, but I need to keep my cuts straight up and down to make channels. It’s odd because if you measure there and the corresponding corner/turn on the opposite side, this one is actually wider, yet the other side looks fine.

One strategy would be to use a V-carve first to remove most of the material - especially in the center, then do an inside Contour toolpath with the 1/16" bit to deepen & sqaure-up the edges of the carve.

That sounds like a great idea. I’ll give that a try.

Thanks!

I would use an Advanced V-Carve in this situation and enable the pocketing feature. You can either select that the pocket is first or after the v-bit. I would suggest pocketing first then v-bit to clear the clear the rest. I do a lot of epoxy and the lines come out nice and straight in the narrow spaces.

The next option is to scale up the Vector until the Bit fits in the hole.

I upscaled the Vector to W 10.75 and H 10.7030 and the Toolpath looks good enough.

It looks even better at 11 x 10.9519

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.