I’ve been trying to learn fusion for awhile and every time I think I’ve got it, something goes wrong. Lately I’ve been having trouble with the finished part size. The outer profiles are too large and the pockets are too small. But the places I spot dill are within a few thou.

All parts had a roughing and a finishing pass. Part B actually had two finishing passes.

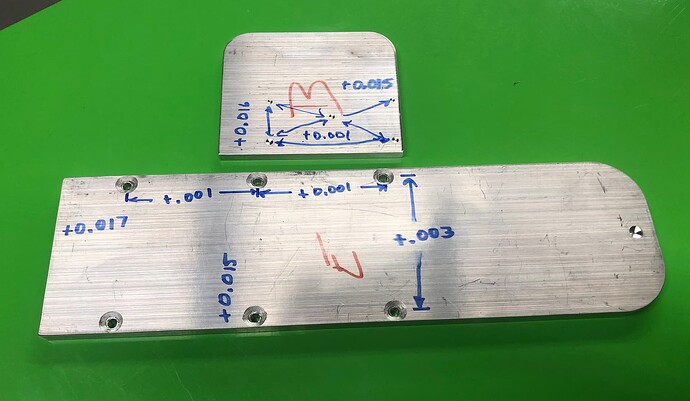

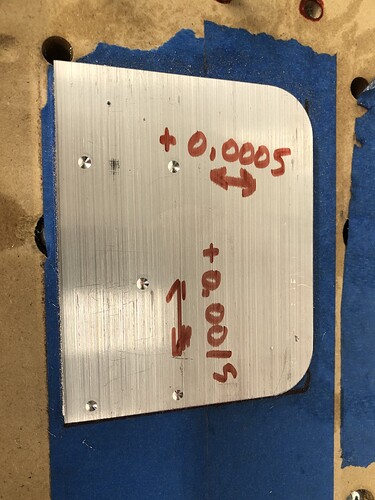

B&E were over sized by 0.015-0.017"

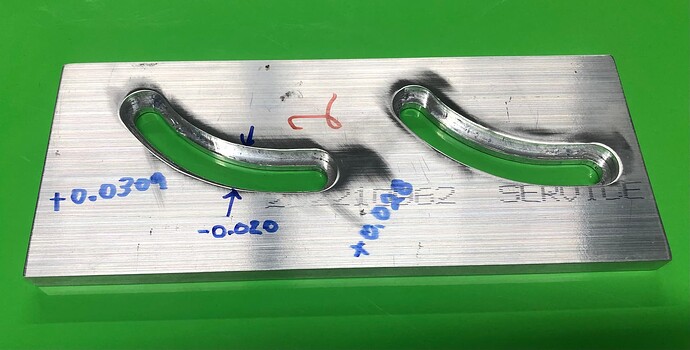

D2 was over sized by 0.028-0.0305" and the pockets were under sized by 0.020". The shelf was 0.003" too deep (not worried about that)

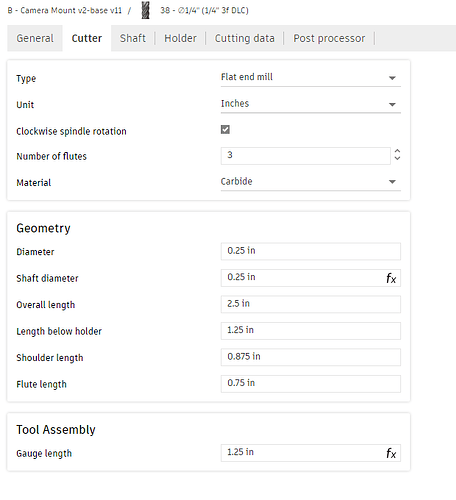

The Bit used is a 0.25" 3F endmill.

Running at 18000rmp

108IPM with air.

Max roughing stepdown was 0.110"

Full depth finishing pass 0.020"

Machine is an S3 with linear rails, ballscrews, an HDZ and a 2.2kw spindle.

Part B

Part D2

Part E

Finish wall pass

EDIT: ADDED VIDEOS that work

https://www.dropbox.com/t/aDuh5tefmEQquqTH

Things I’ve checked.

I put a 123 block (Measured 3.0000") in a vise and found the -x edge with an edge finder, moved over half the diameter, zeroed, found the other side, subtracted half of the diameter. Rotated 90deg and repeated for y.

X was 2.9995" and Y was 2.9990". The machine is accurate enough for me.

Measure diagonally across the oversized finished parts and they were 0.001" off from each other. So it’s cutting square.

I thought maybe my bit was undersized, but when I measured it was 0.2500".

Bit was 1/4" with 3/4" flute length. Stick out was around 1.25"+/-0.0625" , so I would assume there is not much bit deflection.

I put the gcode into NC viewer and the found the finishing pass, found the +x, added the -x and subtracted the bit diameter and the numbers was spot on. I did the same for y and perfect.

Now I’m at a loss and need help. Any thoughts or ideas would be greatly appreciated.