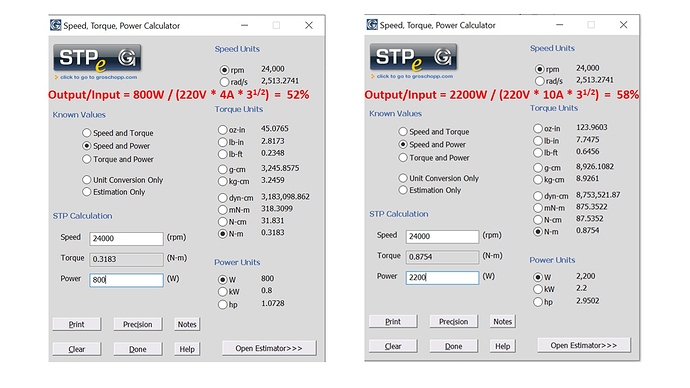

Yup - apparently G-Penny’s spindles, unlike Jianken’s, are realistically rated. Maybe @Luke should change his HDZ anodizing to match? ![]() @Julien verified that the runout on his 2200 Watt version was as advertised too! The calculated maximum torque for that 2200 Watt unit matches that of the “2500 Watt” Jianken in the linked video. IMO the 800 Watt 110 Volt version would be a great spindle upgrade for US Shapeoko users at a fraction of the cost of European spindles.

@Julien verified that the runout on his 2200 Watt version was as advertised too! The calculated maximum torque for that 2200 Watt unit matches that of the “2500 Watt” Jianken in the linked video. IMO the 800 Watt 110 Volt version would be a great spindle upgrade for US Shapeoko users at a fraction of the cost of European spindles.

Festool fans and others with deep pockets might prefer a Mechatron spindle. “The price for our spindle HFP-6508-60-ER11 is 2358€ and the delivery time is approximately about 2 weeks.” But it’s capable of at least 700 Watts of continuous cutting power from 22 - 60 kHz! So, it would be really nice for high speed aluminum milling (@Vince.Fab). Larger units with and without ATC are also available.

2020-01-02 Update: Mechatron also offers constant torque type spindles in both their professional and standard series. A 800 Watt 24,000 RPM constant torque spindle (like @wb9tpg’s) would only provide 400 Watts at 12,000 RPM (and hence half the material removal rate (MRR) at that speed). But limiting spindle torque limits machine forces - that’s a good thing for safety, performance, and machine protection. Those with monster spindles (like @Julien) might even want to consider limiting their torques to “safer” levels with their VFDs. Note that, unlike HF spindles, routers don’t try to limit torque when cutting loads increases. Their stall torques can be as high as 10 times their operating torque. Those who have crashed their routers know how much damage that can do!

Note that the specified maximum fluid temperatures for their liquid cooled spindles is 35C. Do you plan on using a CW-3000 or CW-5000 for cooling?