So I know how to set my zero now I did some engraving at 0.05mm and it came out really good Took a couple times to set the zero perfectly, but I got it. When I decided to do pocketing, it went way past the material. The material is right around 4.4 mm - 4.6 mm. I put two squares to be pocketed to max depth 4.3 mm and a rectangle for my phone at 2.0mm max depth. You can see in the photo how deep it went. Is there something I’m doing wrong? And how can I fix it. I’m using the carbide presets for their tools, but I’m using a different brand since I needed one faster to practice but their the same measurements I don’t know if that matters or not

Are you sure your decimal ended up in the right place when setting the depth? I know that’s how I screwed up once or twice, eyes are not as good as they used to be.

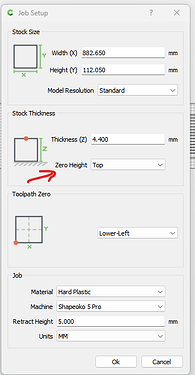

Perhaps the setting for Z-zero reference point was at the bottom of the stock instead of the top in your design?

I used paper to set the Z zero until it I could no longer move it around but I don’t know if that’s the way to do it and my toolpath is lower left

There’s a blog post on this:

https://carbide3d.com/blog/unexpected-z-axis-plunges/

If reviewing:

https://my.carbide3d.com/gswcc/02/

and

https://my.carbide3d.com/gswso/06/

doesn’t resolve this, upload your .c2d file, step-by-step notes on how you are securing your stock and setting zero relative to it and managing all tool changes and a photo showing an attempt at cutting with the machine at the origin or a specified offset from that position.

panel test pocket.c2d (220 KB)

first I tried securing it with carpenter tape the first time I did it and it didn’t work. The second time I did it with the work holding clamps carbide provides. As for the photo I’m not at the warehouse at the moment.

If you were setting the Z-zero via the paper-method on the top of your stock material on the machine, then that would agree with the Setup Settings in your design file.

If you set the Z-zero via paper-method at the bed surface, then your design file needs to have the ‘Zero Height’ set to Bottom - as in Bottom of the Stock material.

If you did all that correctly & it resulted in pocketing into your bed surface, then you need to look at your Z-axis losing steps - whether it’s a mechanical issue or electrical connector.

I was setting it from the top, but Is it maybe because I set my Z axis to zero at the corner? Should I maybe do it in the middle? How can I check if my Z Axis is missing steps? And where should I check? I have a 1 on 1 training tomorrow with carbide 3D I’ll ask them about it as well. (edit) also I didn’t check the toolpath in carbide motion before I started it