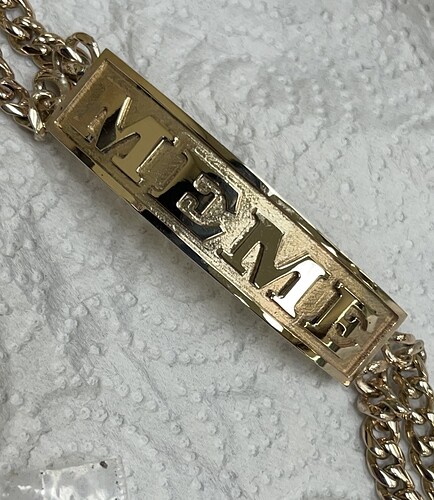

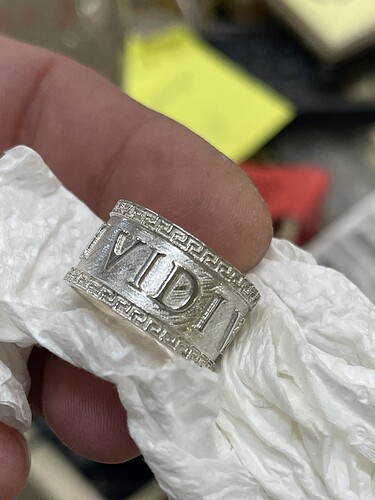

I’ve been doing this names in gold and silver with the 122 bit along with the carbide create software, my question is I am adding the same tool to fusion 360 dimentions and all and looks like there is some places where the bit can’t reach some places maybe I am doing something wrong.

Check the tool in the library in Fusion. Confirm the length under the collect.

The #122 is 1.5 OAL . The VFD collect is 5/8" full engagement.

The length under the holder should be 7/8" ( 0.875) in the Fusion Tool library.

Are you getting a crash in Fusion simulation or just not contacting the part when running ?

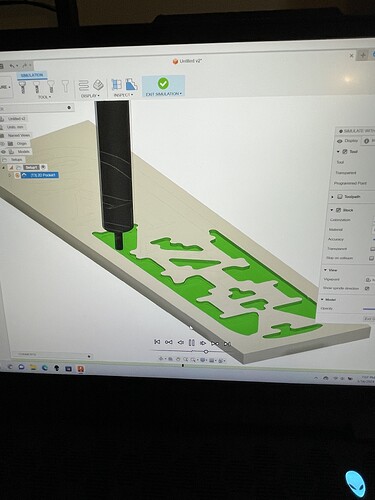

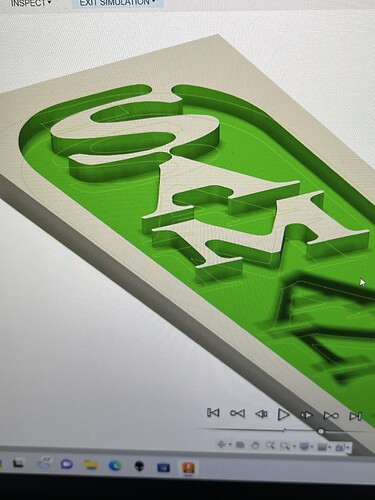

On the simulation letters are incomplete

I would look at …

The Stock versus the part to confirm alignment in the Setup

The Tool Heights in the Operation. You can look edge wise to confirm you are deep enough.

I am assuming the part face of interest is aligned to the XY plane in Design

The Design sketch or solid looks like ?

Hopefully someone that has a clue will jump in

Tool too large to fit in the small detail areas?

How about …

I do not know what type of milling process you picked. I would guess 3DAdaptive .

In the Operation dialog, Select the Pass tab

There is a check box for Stock to leave and the value is 0.020 ( for inch models).

If it is selected, uncheck it. That way the tool will go to the feature geometry.

If you are using another milling operation, look for same option.

Carbide create 7 is amazing and I’m still using it in my projects I just want to learn more and you guys are helping a lot thank you very much.!IMG_0386|375x500](upload://78roEH3qmdJp4yrMoFIlqwbluJK.jpeg)

This topic was automatically closed after 30 days. New replies are no longer allowed.