The SVG or DXF? I find it’s best to fix things before importing into Carbide Create.

Svg.Is that why im having so much trouble assigning toolpaths is because the svg isnt right? and how do i fix it?

Post the file, I’ll look at it, and tell you exactly what I have to do to fix it.

That SVG seems to be fine and work fine once loaded into Carbide Create — looks good!

I think i finally am onto somthing,do you have a way to look at this?mazefinal1.egc (699.7 KB)

If you loaded the Fusion file, why don’t you simply use the CAM part to produce the g-code? There is a post processor in Fusion for the carbide board that works very well.

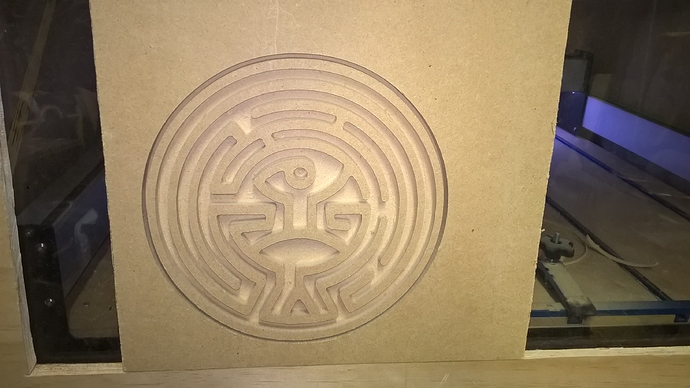

I know how to use fusion even less than cc,I also want to learn cc( thanks for the heads up tho @jeff)…,I ran the file i uploaded previously in some mdf and other than not taking a measurment with calipers on the stock it came out great,i had the cutout depth set at 0.250 ish and unfortunatily it was 0.272,non the less turned out well,ill do another in some real wood .

Nice, sounds like you got your circles right

Please refer to the original picture, the bottom triangle is not touching on either side and there is also a closed path a 10 o’clock from the head.

As for Fusion, I must say that if you played at all with any CAD package, it is not that hard.

I found Lars’ videos https://www.youtube.com/user/cadcamstuff/videos quite helpful on the CAM side.

I have to admit, I probably spent a good 10 hours learning about CAM operations, and using the help on each text entry found in the Fusion dialogs, I learned enough to do my projects, but I will not call myself a master CNC man yet. The CAM preview in Fusion saved me hours of “bad” machining time!! The preview is the best way to learn, hands down.

The main reason I work with Fusion is that, I gave up on using Sketchup to create designs for my 3D printer. The STL export is bad (sucks) and you always have to use Netfabb or some other tools to fix the STLs. With Fusion, I draw one thing and I can send it to either my CNC or my 3D printer.

That for me, is worth the price of spending a little time to learn the software.

Thanks for the advise  i will watch the vid,what printer do you have? I couldnt get fusion to see my ctc dual w/sailfish 7.7

i will watch the vid,what printer do you have? I couldnt get fusion to see my ctc dual w/sailfish 7.7

Its one I build myself based on CoreXY http://www.thingiverse.com/thing:313095

Actually, I use Slic3r to transform the STL produced by Fusion and place them on an SD card. Then, I use my Viki LCD coupled to an Azteeg X3 (both from Panucatt) to print.