I would like a recommendation on good quality & powerful enough laser attachment. I’m currently running a water-cooled 80mm 2.2KW spindle using Mr. Beaver’s HDZ. Sincerely appreciate your recommendation.

I just added the jtech 7 watt to my shapeoko 3xxl today

still getting a feel for it, but my first impression is that it is pretty slow, that being said the installation, and lightburn configuration was a snap, was up and running in a little over a hour and half. I was looking at this and the Chinese 40 watt co2, which is more capable, but requires alot more tinkering, and can be dangerous or even fatal if grounding rails.

I’ve been using the OdicForce solid-state lasers and I like them. I had an issue with one of their driver boards and got great support; they sent a new board and cables to me from England, free of charge. I can also contact someone there by email with great response, so I’d consider that great support. The laser has been very reliable so far. I bought a 5W solid-state laser - great for engraving. No issues with the laser module so far, just the power-supply board which, again, they fixed. I’ve sent them several tech questions and I feel they’ve provided very good support. I use LaserGRBL for my driver software.

There is a laser port on the Shapeoko Control Board. Does this port allow us to connect a laser head directly to the Shapeoko Control Box?

The community has some notes on this at: https://wiki.shapeoko.com/index.php/Laser_Cutter

Note that such 3rd party accessories void the warranty.https://carbide3d.com/warranty/

In a word, no. In more words, an add-on laser is basically three parts: a controller (with power supply), a laser module, and some type of mounting system. You connect a ground pin and a PWM signal pin between your Shapeoko controller and the laser controller, and the power (as it were) of the laser is set by your G-code and passed to the laser controller. (You must use a non-Carbide Motion G-code sender, e.g. UGS, cncjs, etc.)

Since you don’t need to do any modifications to the controller (both PWM and ground are actually available as existing pins in a block near the power connection end), using an add-on laser will absolutely not void your warranty under United States law, however, if you or your laser controller fries the Carbide Controller board, that’s on you and would not be covered by warranty. (Something completely unrelated would still be covered, although controller issues seem exceedingly rare.)

Regarding lasers, however, you need to know what you’re wanting to get out of the thing. If you’re primarily interested in laser cutting, you most likely do not want to add a laser to your Shapeoko. While it is possible to cut thin materials using a solid state laser module, compared to even the cheap Chinese “40W” CO2 lasers, it’s very slow. On the other hand, if you’re most interested in something like laser-engraving, e.g. marking wood projects, an add-on laser module is the least expensive and most versatile approach.

Shapeoko + Laser examples:

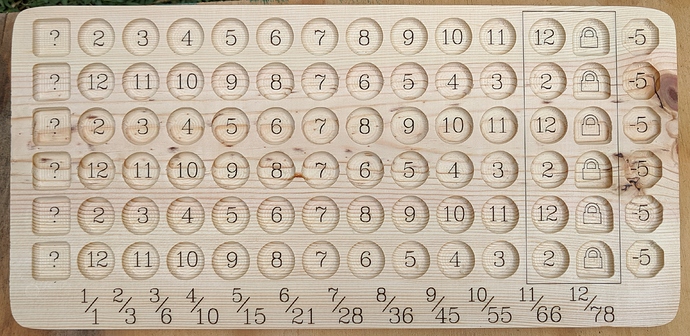

Here’s a game board of mine with all the text laser-engraved:

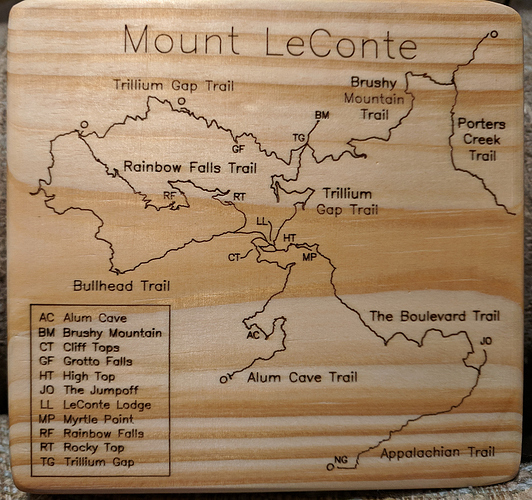

And the map on the back of one of my terrain relief models:

The trails on the 3D terrain relief model are especially well suited for engraving with a laser module on my Shapeoko, as I can use the full Z-axis data with the laser, giving excellent results:

Standalone Laser Cutter example:

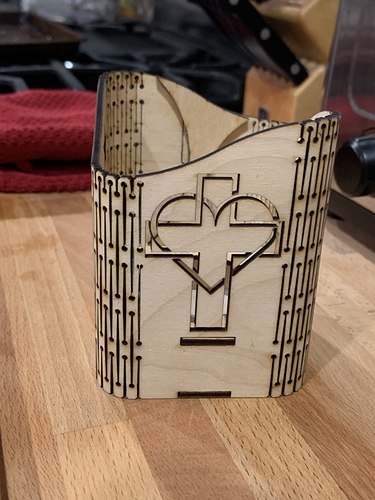

This is from Dan, who commented about taking 14 minutes (on the laser cutter) instead of 3 hours (on a Shapeoko with laser and air assist, IIRC):

Yes, that is one of mine. I’m running a 50 watt Chinese CO2 laser at a single pass, 50% power, 11mm/sec (26 ipm). I made several of those with my 7 watt diode and it was more like 6 passes at 100% power and 4.6mm/sec (11ipm)…if my math is correct it take over 14x as long to cut the same thing with the diode compared to the CO2 and the failure rate is higher, and trickier to get setup correctly. The big downside is my working envelope. I get 12"x20" of working area on the CO2, and on the diode I get to use the size of my XXL bed (mostly). If I had to do it all over again (for the third time) I’d go straight off with a 60-80 watt CO2 and a larger bed. I can’t say anything about the quality of the smaller Chinese K40 machines, and I’ve seen some horror stories, but my 50 watt is a very solid machine. Worked out of the box, but took a little tweaking to get just right. Parts seem to be readily available too, and they’re actually pretty simple machines much like a SO3. The JTech kit is also very high quality and tech support is great. All kinda matters what you wanna do, cut or mark. Also the size of your projects. Every tool has a specific use.

Dan

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.