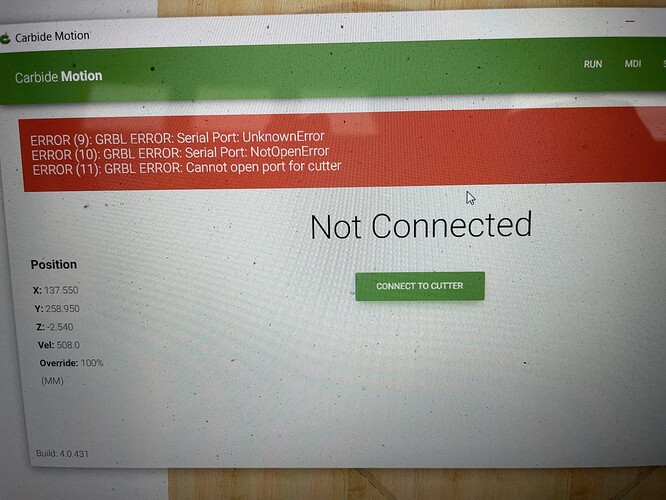

Hello, I come once again in search of help from you guys  . I was cutting today (I haven’t used my machine in a week) and I got an error in the middle of my cut. I reconnected and it started again and about 3 minutes in got another error. I plugged in my usb isolator and it seemed to work and then it did it again. Retried once more and it still didn’t work. I keep getting multiple errors with and without the isolator. Any thoughts? Also the cutting quality is FAR WORSE than usual, and it’s a brand new bit that I’m using. Could that be caused by the grbl issues? Thank you

. I was cutting today (I haven’t used my machine in a week) and I got an error in the middle of my cut. I reconnected and it started again and about 3 minutes in got another error. I plugged in my usb isolator and it seemed to work and then it did it again. Retried once more and it still didn’t work. I keep getting multiple errors with and without the isolator. Any thoughts? Also the cutting quality is FAR WORSE than usual, and it’s a brand new bit that I’m using. Could that be caused by the grbl issues? Thank you

Grbl should just send the signals to move the machine as it ought — I suspect what happened here is that the depth changed slightly — re-running a finishing pass for the pockets should help.

Do you know why carbide motion kept spitting out errors and disconnecting? I don’t want to do another pass that should take 32 minutes and in reality takes 2 hours. Thank you though! That does make sense. 1 part down 1 to go

For the disconnect see: Electronics - ShapeOko or write in to support@carbide3d.com

1 Like

I’ve done everything in the list. I’m waiting for a response from support. Thank you!!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.