You are making me drool…

What would you like to know @griff? It’s the best way to go about modularity. Bolt on low profile vises, bolt on consumable sub plates. I asked about a sub plate with locating pin as well.

I’ll be using the SMW stuff exclusively so we’ll see if any issues come up.

I have to wait for my own SMW fixture plate setup because they haven’t made stock yet. But until then…

Psssss @Julien

Making my mouth water, I wonder the cost if they made one in the XXL size…

I dont think its kosher to start spitting prices but they are up on the website, photos coming soon.

That right rail shifting slightly at 0:06’ makes me uncomfortable though

(desperate attempt to find reasons to not cave in and order rails)

I know you saw the clamps in the back. I decided to call it a day when indicating 0.012 across the X.

I know you saw the clamps in the back. I decided to call it a day when indicating 0.012 across the X.

Never adjust a v wheel again, reason enough?

Oh my. I was so focused on that sweet gliding action that i DID NOT see the huge clamps ![]()

Brings back memories of not seeing the walking bear…

That would be incredibly hypnotizing if the video was trimmed and looped. I need to get my Y-rails done.

This is what I’ve been wanting, but is so dam expensive to ship to Sweden

Nice. I’ve been doing my version of that for a while now with my secondary MDF boards with 1/4” steel dowels. Drop on, automatically aligned, bolt down.

What I’ll probably do, although the SMW price for the XL plate is really quite reasonable considering the number of holes and level of precision, is try out the approach using MDF. Maybe buy some of the fixturing from Saunders.

Since I’ll not be subjecting my machine to steroid abuse, more power to those who do, I’ll live within the limitations of v-wheels and belts and the degree of precision they offer to this woodworker.

If precision aluminum parts rise on my priority list I’ll probably go for a Nomad 3 rather then spending the same amount of money modding my XL. That’s just me though.

Totally understandable, 24krpm on the Nomad 3!

One step closer to the ultimate S3 over here. Corners tapped and bolted. The large shop surface plate really helped with Y plate alignment.

The C3D billet plate is about 0.010 out

Welcome to the Club… I love my SMW plates and Modvise although my center brace does not have feet like the outer 2 but they are Beta versions. I see they fixed the overhang of the braces on the edges. Are you using low profile hardware or did they make the counter bores for the brace bolts deeper?

I recommend using lock-tite on the bolts that attach the plates to the black Shapeoko cross braces. If they come lose the bed will rise as the machine is now supported by the bed instead of the black rails.

never mind I got it resolved

Can you show some photos of what you’re seeing? Also the resolution?

I do know that we are continuing to develop the larger xl and xxl sizes to assemble flat. The regular S3 with stiffeners should be good to go.

I haven’t used loctite but torqued everything down pretty good. Its probably a good time to recheck them and add a bit of blue one by one.

I didn’t see this before. Did you plug in measured currents for this cut?

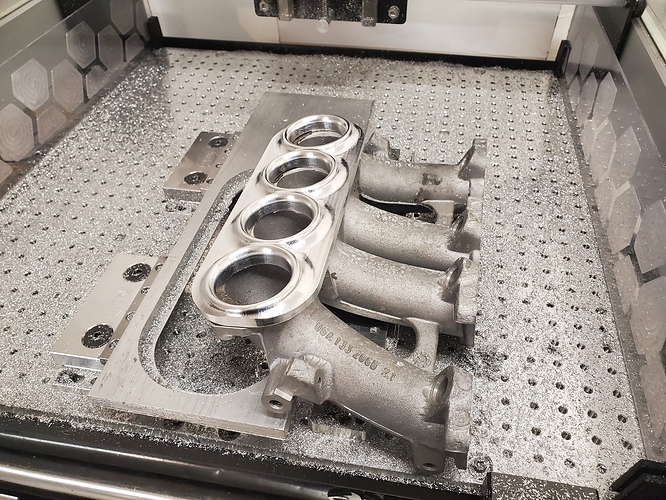

Chipping away at stock s3 capabilities

Datron 6mm 4-1 @ 30,000rpm 150ipm roughing

Datron 6mm SF Ball for scallop finish, no post processing or polish.

Hey Vince, where did you get your aluminum clamps??

Thanks

Modvise by Saunders Machine Works

Doh, was hoping they were 3/8" not 1/4"

There’s a half inch mounting bolt version as well. Its surprising how well the 1/4 ones hold though.

Is your plate tapped for 3/8s?