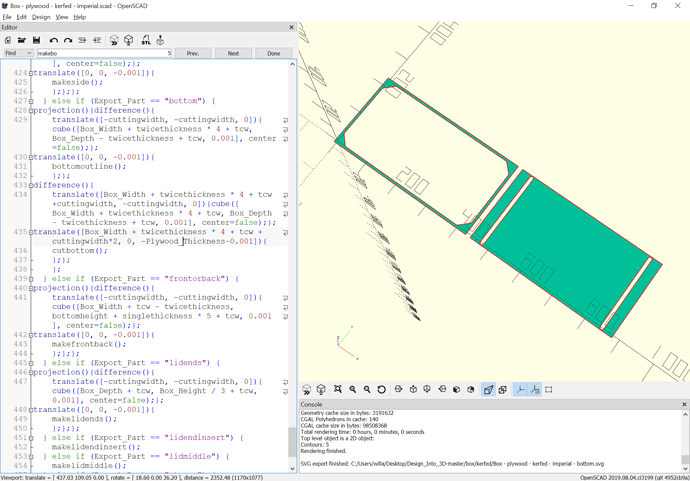

For parts which have V cuts the V cuts are output in addition to the actual part outline surrounded by a rectangle of the same size:

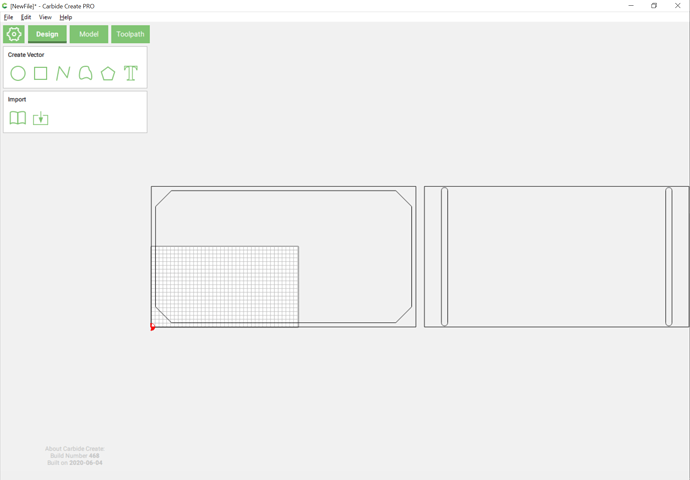

this allows them to be imported into Carbide Create:

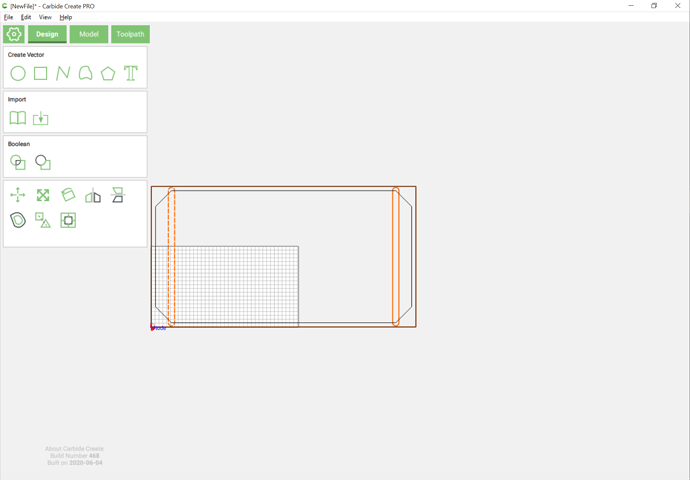

and the two cuts dragged into register:

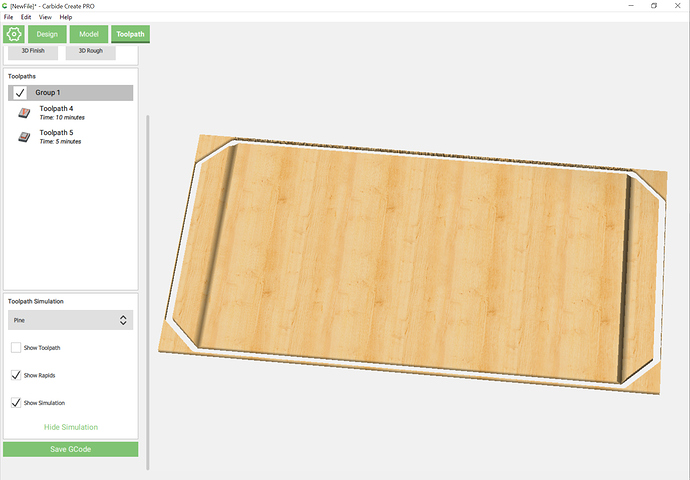

and appropriate toolpaths assigned: