OK, so I’m pretty sure the shape settings do not come on Carbide Create with settings for 20° bits.

So I made my own tool in the program. This was my first time so I may have done something wrong. I made a 20° bet and named it 20 so I could tell what it was later because for some reason you can’t really name the bit you want here.(I find this too be a flaw as it forces me to use random numbers that someone has chosen for the bits to represent that have no relation to what they are)

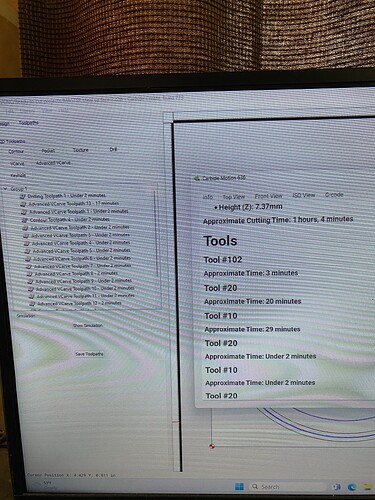

I’m not sure exactly how this is happening, but by the time I make my tool paths and bring them into Carbide motion, they get read as two different tools, causing The machine to shut down and wait for me to tell it I switched tools, even though it has the proper tool on it. I will post a picture, but what it shows is when tool path with tool 10 and the next tool path with tool 20, which are both the same tool, but it still makes me shut down to switch them.

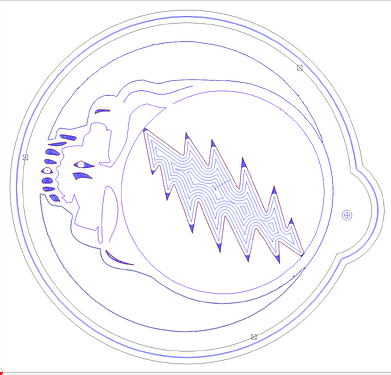

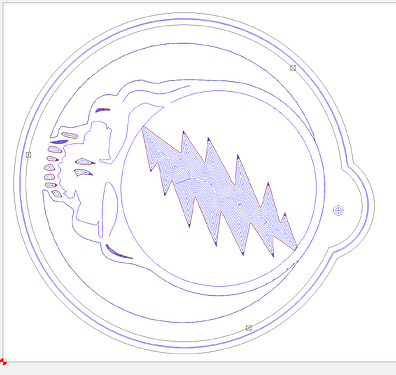

I wanted to add that I tried to make the small teeth in this, which are the ones giving me trouble with the 20 bit and cc won’t carve them as if there isn’t enough room. But in advanced VC if it cuts the pockets, I believe it may have something to do with the advanced VC with the tool switching every tool path. I’m working on the answer now any input would be great thank you.

Here is the carve as you can see there seems to be plenty of room to carve those teeth. The only thing wrong with this Tool path set is that I have to keep changing the bit when it should just run the entire project through after the first bit change until the profile at the end

How can I find out what tool 10 is?

Reorganize your tool paths so you are cutting all the paths with the same bit if possible.

It’s common when creating the toolpaths you will need to rearrange things so that aren’t having to do a ton of bit changing.

Sometimes you can’t do that, if there is a pre-requisite cut, but in general you can move those paths around.

Yes, you don’t see the tool number unless you include it in the name.

If you look in the library, or click “Select Tool” from the toolpath tool dialog, then the tool number is at the top of the Cutter Information listing.

It looks like you are doing Advanced V-Carve toolpaths, which use 2 cutters.

When you make a custom tool, CM doesn’t know which tool it is. All it knows is the tool number, so that’s all you see. If you use one of the default CC tools, CM references that tool information internally from the same tool database, and can ask for it by the tool name.

Sorry I missed what the answer to That was. What’s the best way to handle the issue?

Also not sure why you have so many toolpaths, based on the image you shared, that should only be a couple to achieve that. 3-4 i would think, not 15+ like you have in that image.

The image you shared doesn’t look vcarved, just looks a profile cut and some pockets.

Can you share the file so we can look at it?

I will try and answer this question as best I can. It’s quite confusing.

For some reason when I choose all of the teeth and tell it to pocket cut them, which is what I’m actually trying to do it just won’t cut the tool path at all, as if there’s no room there for it then when I choose the exact same set with the Advanced Vcarve command it will carve but it splashes all the teeth up as if its cutting a little too much off and the thin pieces of wood break and look bad.

And when I choose each tooth separately, the result is the piece of wood shown in the picture which is in my opinion pretty good.

MASTER steal ya face 2.c2d (388 KB)

this is the file im working with with all the toolpaths on it thank you for your help !

Before you do too much work, I just grouped them all together and it looks like it’s gonna work so I will go try to cut it and that would get rid of the tool changing problem. I’m not sure what happened before to make me think it wouldn’t work thanks again for your input. I’ll get back on here and let you know what happened.

Usually that means the bit is too large, aka the toolpath is empty. I don’t use carbide motion very much but i assume you should be able to see that if you run the simulation, those are usually pretty good indications of what it will look like.

a V-carve bit can obviously cut a very small area since it has a pointed tip versus an endmill.

Do you know if Carbide Create allows you to use a V bit in pocket because I see no reason it shouldn’t allow me to carve it because it obviously fits in the space while telling me it won’t fit in the space for pockets. Any ideas on that?

When a V tool is used for toolpaths other than V carving, the dimension used for testing fit is the largest (at the top of the V).

So a tiny little pockets would you say that advanced V carve is the proper way to go about that?

Yes, fine details are best cut with a V carving toolpath (if sloping sides are acceptable).

You have your McFly cutter set for the Advanced V-Carve clearance bit. This is not going to fit in any of the pockets. I grouped all the Advanced V-Carve object so they could be one tool path and substituted the #102 0.125" endmill for clearance. even with the 0.125" end mill there are only a few feature where it will fit.

Using the 0.0625 #112 for clearance gets more of the features. This is when you could optimize cutting time with more tool changes using the 0.125" for the larger features and the 0.0625" for the smaller ones.

OK, so your Advanced V-Carve path uses tool #20 named “20 DEGREE”. Your Contour path uses tool #10 named “v 20 degree”. 2 different tools with different numbers.

Select the contour path & change the tool to the same (#20) tool. Or just edit the #10 tool & change the tool number to 20.

When you’re selecting the tool from the library, the tool number (along with the vendor & model) are at the very top of the listing.

As for the many toolpaths, you can combine all the Advanced V-Carves into 1 path, and the contours into a single path. Then you just have Drill, Pocket & final contour around the outside. 5 paths total. And only 2 toolchanges.

You also have a bunch of duplicate vectors, and a few really tiny vectors. I would clean those up so you don’t accidentally select them for machining.

Are these vectors supposed to look that ‘jaggety’??

They are the same tools chosen from the same place in the same menu and then they show up differently every other time I use them