I looked at the grease nipples supplied with my Hiwin rails, the Hiwin manual and the HDZ and there’s a few things to note.

Putting grease on the rails won’t do much, the wipers on the blocks will clean this off fairly quickly, we need to get the grease inside the rail block grease reservoir where it can lubricate the bearings.

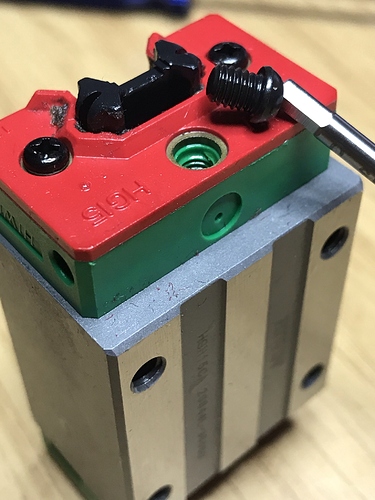

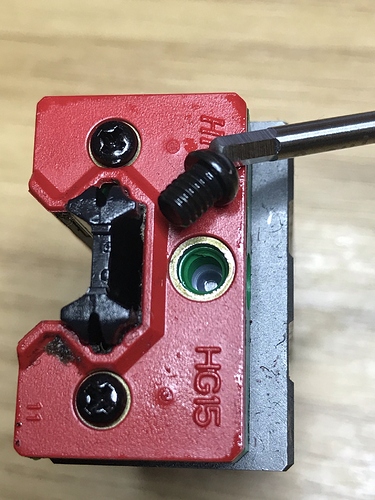

Most linear rail blocks have a range of grease port locations scattered around their surfaces that provide access to the grease reservoir built into the block, on the Hiwin and on the HDZ rail blocks there are pre-drilled ports on both ends;

These are M4 threaded on most HGR15 clones so US users beware, her majesty’s imperial pipe threads are unlikely to fit. There are also marked locations where you can drill through a ‘non-standard’ hole but we don’t need to do that.

Hiwin supplies some grease nipples with their blocks but I am not sure what sort of gun (other than the expensive Hiwin linear rail block 70g grease gun) you would use them with as they are hexagonal and not round.

The other issue, and presumably the one which stops Carbide from shipping the HDZ with grease nipples installed (there’s no excuse for the lack of maintenance instructions though) is that these would stick out of the bottom of the HDZ and likely catch on the workpiece or clamps and get torn out of the rail blocks if you left them installed. If you do want to use grease nipples search eBay for “M4 zerk nipple”.

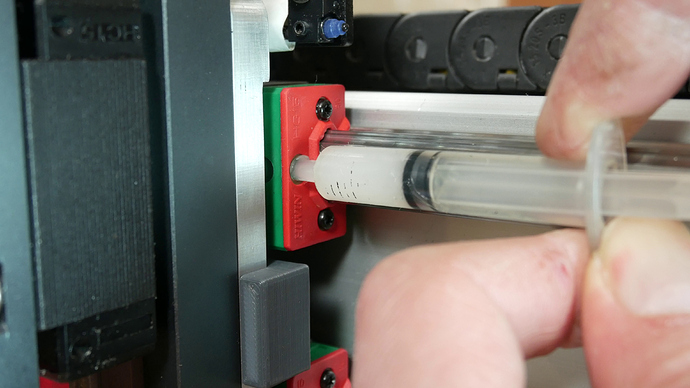

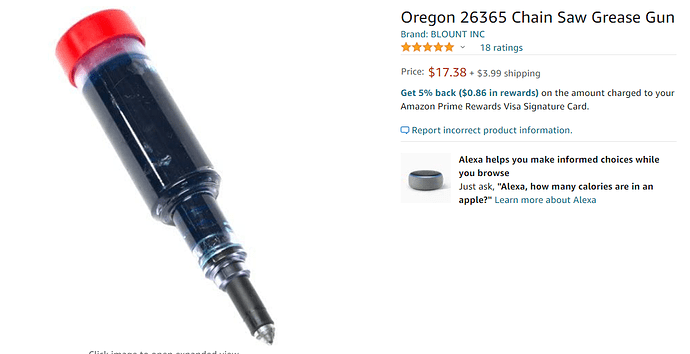

I have successfully used a small syringe (just the plastic bit no needle attached) to suck superlube out of the tube and squirt it into the blocks, a small O ring can help get a seal there so you can get a bit of pressure on the grease. Or use something like this

https://www.amazon.co.uk/Sealey-AK55-Push-Type-Grease/dp/B07WZTP4YC

Unscrew the grease port screw, syringe or otherwise squirt grease into the port, don’t over-pressure or overdo this, you’re just trying to get grease into the chamber, not jet it out the other end. Then stick the screw back in and run the block up and down the rail a few times. It’s easier to do all this with the machine powered up as it holds the blocks stationary for you and makes jogging easier to work the grease around. Remove the screw and squirt grease in again, jog around. Hiwin suggest three rounds of this.

Again, the Hiwin instructions say that you should regularly clean and inspect the rails, so occasionally wipe them clean before using the machine, don’t use solvents or other cleaning agents. You should then be able to spot when the grease needs topping up as after wiping clean you won’t get a film of grease on the rails after the machine moves.