Yes it’s shareable. I also use it at work for a wire EDM and was able to make a small change years ago. That post was quite different from a milling post so I was able to make the changes. Now anytime I make any changes it gives an error. I’m sure there is a manual somewhere, but I wouldn’t know where to find it. Here is the text in the post

************************** SYSTEM VARIABLES ****************************

POSTNAME : YCM XV MXP200I 01/12/06

XSTART : 0

YSTART : 0

ZSTART : 0

UPPERCASECOMMENTS : 1

TOOLCHANGE_HIGHZ : 999.9999

MACHINETOLERANCE : 0.0001

**************************** MACHINE MODES *******************************

COORDINATEMODE : ABSOLUTE

MEASUREMENTMODE : INCH

CIRCLEMODE : FULLCIRCLE

CENTERMODE : INCREMENTFROMSTART

RAPIDMODE : PLUNGE

WORKPLANEMODE : XYPLANE

RETURNPLANEMODE : RRETURN

MILLRETRACTMODE : MILLPLUNGE

LENGTHCOMPOUTMODE : TOOLCHANGEONLY

************************* FORMATABLE CODES *******************************

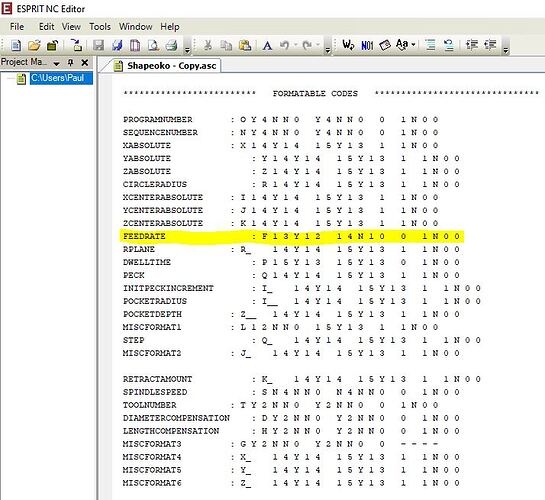

PROGRAMNUMBER : O Y 4 N N 0 Y 4 N N 0 0 1 N 0 0

SEQUENCENUMBER : N Y 4 N N 0 Y 4 N N 0 0 1 N 0 0

XABSOLUTE : X 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

YABSOLUTE : Y 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

ZABSOLUTE : Z 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

CIRCLERADIUS : R 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

XCENTERABSOLUTE : I 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

YCENTERABSOLUTE : J 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

ZCENTERABSOLUTE : K 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

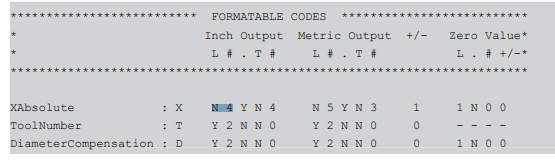

FEEDRATE : F 1 3 Y 1 2 1 4 N 1 0 0 1 N 0 0

RPLANE : R_ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

DWELLTIME : P 1 5 Y 1 3 1 5 Y 1 3 0 1 N 0 0

PECK : Q 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

INITPECKINCREMENT : I_ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

POCKETRADIUS : I__ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

POCKETDEPTH : Z__ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

MISCFORMAT1 : L 1 2 N N 0 1 5 Y 1 3 1 1 N 0 0

STEP : Q_ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

MISCFORMAT2 : J_ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

RETRACTAMOUNT : K_ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

SPINDLESPEED : S N 4 N N 0 N 4 N N 0 0 1 N 0 0

TOOLNUMBER : T Y 2 N N 0 Y 2 N N 0 0 1 N 0 0

DIAMETERCOMPENSATION : D Y 2 N N 0 Y 2 N N 0 0 1 N 0 0

LENGTHCOMPENSATION : H Y 2 N N 0 Y 2 N N 0 0 1 N 0 0

MISCFORMAT3 : G Y 2 N N 0 Y 2 N N 0 0 - - - -

MISCFORMAT4 : X_ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

MISCFORMAT5 : Y_ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

MISCFORMAT6 : Z_ 1 4 Y 1 4 1 5 Y 1 3 1 1 N 0 0

************************* SYMBOLIC CODES ***************************

MOTIONRAPID : G00

MOTIONLINEAR : G01

MOTIONCW : G02

MOTIONCCW : G03

DWELL : G04

SPIRALCW : G12

SPIRALCCW : G13

XYPLANE : G17

ZXPLANE : G18

YZPLANE : G19

INCH : G20

METRIC : G21

ZERORETURN : G28

COMPENSATIONOFF : G40

COMPENSATIONLEFT : G41

COMPENSATIONRIGHT : G42

COMPENSATIONPLUS : G43

COMPENSATIONMINUS : G44

LENGTHCANCEL : G49

WORKSYSTEM1 : G54

WORKSYSTEM2 : G55

WORKSYSTEM3 : G56

WORKSYSTEM4 : G57

WORKSYSTEM5 : G58

WORKSYSTEM6 : G59

INZONEPOSITIONING : G64

CANCEL : G80

DRILL1 : G81

DRILL2 : G82

PECK1 : G83

PECK2 : G73

TAP1 : G84

TAP2 : G74

BORE1 : G85

BORE2 : G86

BORE3 : G76

BORE4 : G89

ABSOLUTE : G90

INCREMENTAL : G91

SETORIGIN : G92

IRETURN : G98

RRETURN : G99

PERCENTSIGN : %

PROGRAMSTOP : M00

OPTIONALSTOP : M01

REWINDSTOP : M02

SPINDLECW : M03

SPINDLECCW : M04

SPINDLEOFF : M05

TOOLCHANGE : M06

COOLANTON : M08

COOLANTOFF : M09

ENDPROGRAM : M30

MISCSYMBOLICCODE1 : Y0_Z0

**************************** EXAMPLES ********************************

VARIABLE : StartPointFlag Test Tap

EX_STARTPOINT : IF (StartPointFlag)

: G00 G90 WORKSYSTEMCODE* X Y IF(Tap<>(4))S SPINDLEDIRECTION ENDIf

: G43* H* Z_(initialclearance) M08 IF(nexttool>0) T(nexttool) ELSE T(firsttool) ENDIF

: IF (nextdim(3)<>initialclearance) Z ELSE NCOUTPUTOFF Z NCOUTPUTON ENDIF

: StartPointFlag=(0)

: ENDIF

EX_RAPID : IF (StartPointFlag) EXITEXAMPLE ENDIF

: G00 X Y Z

EX_LINEAR : Test=(nextclfile(631))

: G01 X Y Z F

EX_CIRCLE : IF (xpresent = xlast && ypresent = ylast)

: G17 CIRCLEDIRECTION X Y Z I* J* F

: ELSE

: G17 CIRCLEDIRECTION X Y Z R* F

: ENDIF

EX_CIRCLEZX : IF (xpresent = xlast && ypresent = ylast)

: G18 CIRCLEDIRECTION X* Z* I* K*

: ELSE

: G18 CIRCLEDIRECTION X* Z* R*

: ENDIF

EX_CIRCLEYZ : IF (xpresent = xlast && ypresent = ylast)

: G19 CIRCLEDIRECTION Y* Z* J* K*

: ELSE

: G19 CIRCLEDIRECTION Y* Z* R*

: ENDIF

EX_COMPENSATION : G01* COMPENSATIONSIDE X Y Z D F M08

EX_COMPENSATIONOFF : G01* G40 X Y Z F

EX_CYCLESTART : COMMENT(1)

EX_TOOLCANCEL : “Z5.0” M09*

: “G91” G28* “Z0” M05*

: M01*

EX_PARK : IF (PARKRETURNCODE = PARKRETURNYZ)

: “G00 G53 Y0 Z0”

: PARKRETURNCODE*

: BLANKLINE

: COMMENT

: BLANKLINE

: G43* H* Z_(initialclearance) M08

: ENDIF

VARIABLE : opnum

EX_STARTCODE : opnum=(0)

: %

: O* PROGRAMNAME

: “(YCM XV.ASC 11/10/06)”

: BLANKLINE

: “( ******* PART SETUP INFO ******* )”

: BLANKLINE

: SETORIGINCOMMENT

: BLANKLINE

: “( ******* TOOL SETUP DATA ******* )”

: BLANKLINE

EX_TOOLDEFINITION : TOOLCHANGECOMMENT

EX_MAINSTART : BLANKLINE

: “( ******** PART PROGRAM ********* )”

EX_FIRSTTOOLCHANGE : BLANKLINE

: N(presenttool) G00* G17* G28* G40* G80* “G91 Z0”

: T* M06* TOOLCHANGECOMMENT(1)

: StartPointFlag=(1)

: Tap=(nextclfile(110))

EX_OTHERTOOLCHANGE : BLANKLINE

: N(presenttool) G00* G17* G28* G40* G80* “G91 Z0”

: T* M06* TOOLCHANGECOMMENT(1)

: StartPointFlag=(1)

: Tap=(nextclfile(110))

EX_LASTTOOLCHANGE : BLANKLINE

: N(presenttool) G00* G17* G28* G40* G80* “G91 Z0”

: T* M06* TOOLCHANGECOMMENT(1)

: StartPointFlag=(1)

: Tap=(nextclfile(110))

EX_ENDCODE : G28* “Y0”

: T*(firsttool) M06*

: G90* M30*

: %

EX_DRILLSTART : COMMENT

: RETURNPLANECODE* DRILLCYCLECODE* X Y Z* R_* F* M08

EX_DRILLBODY : RETURNPLANECODE DRILLCYCLECODE X Y Z R_ M08

EX_DRILLCANCEL : G80*

EX_DRILL2START : COMMENT

: RETURNPLANECODE* DRILLCYCLECODE* X Y Z* R_* F* P* M08

EX_DRILL2BODY : RETURNPLANECODE DRILLCYCLECODE X Y Z R_ F P M08

EX_DRILL2CANCEL : G80*

EX_PECKSTART : COMMENT

: RETURNPLANECODE* PECKCYCLECODE* X Y Z* R_* Q* F* M08

EX_PECKBODY : RETURNPLANECODE PECKCYCLECODE X Y Z R_ Q F M08

EX_PECKCANCEL : G80*

EX_TAPSTART : COMMENT

: “M29” S*

: RETURNPLANECODE* TAPCYCLECODE* X Y Z* R_* F* M08

EX_TAPBODY : RETURNPLANECODE TAPCYCLECODE X Y Z R_ F M08

EX_TAPCANCEL : G80*

EX_BORESTART : COMMENT

: RETURNPLANECODE* BORECYCLECODE* X* Y* Z* R_* P* F* M08

EX_BOREBODY : RETURNPLANECODE BORECYCLECODE X Y Z R_ P F M08

EX_BORECANCEL : G80*

**************************** END EXAMPLES *********************************

I know I have to make the changes in the first tool change area, but every time I change anything I get an error.