Hi guys, I could really use some help. I just made a file that on the simulation came out the way I want it and when I cut, it came out completely different in a certain way if anyone would be so kind to look at these pictures and direct me on how to not have this happen again I would very much appreciate it.

OK, so it looks like you have a contour cut to cut the grooves in the middle of each piece, then a profile cut to cut each piece out. The profile cut is too aggressive. Try changing your depth of cut on the tool to a smaller value. Rule of Thumb is less than or equal to half the tool diameter.

It also looks like you are “slotting”, cutting a slot the same width as the cutter. The cutter is engaged 100%, or the whole width of the cutter. And as the cutter moves down to the next depth of cut, it can pinch chips between the cutter & the stock.

Try offsetting the outside vector & using a pocket path between the vector & the offset.

Watch it when it cuts, or verify it using a NC verification/simulation program, to make sure it’s making 2 cuts on the same level before advancing to the next level. Rather than cutting a single slot, then another slot to make it wider. (CC does still do this occasionally.)

I think you may have missed what I was trying to show the second cut completely misses where it supposed to be and it’s not at all the way the simulation shows it it seems that it flipped the contour cut 180° and then registered it off the opposite side of the machine

Are you cutting slots just as narrow as the tool?

I’m sorry I’m not sure exactly what you are asking. I am cutting a contour around the outside of each set of legs for a food serving trey. I did this yesterday no problem but when flipped over and moved the items in cc to lay them out on a different shape piece of wood the problem happend when I next cut the above pic.

Please post the file and we will check it out with you.

You have checked that the machine is electro-mechanically sounds with all wiring in good condition and all connectors secure, and lubricated as appropriate?

I will attempt to post the file I have to go into my house to my other computer. I can’t do it from my phone and my CNC is not hooked up to my Internet at all.

I have checked the connections best I can up until now I’ve had no problems and I’ve got about 200 items made so far

To be clear what I’m most upset about is how can the simulation show one thing and the machine cut something completely different?

The machine only has sensors to determine the home position.

Every movement away from that has the possibility of lost steps, and each lost step compounds the error.

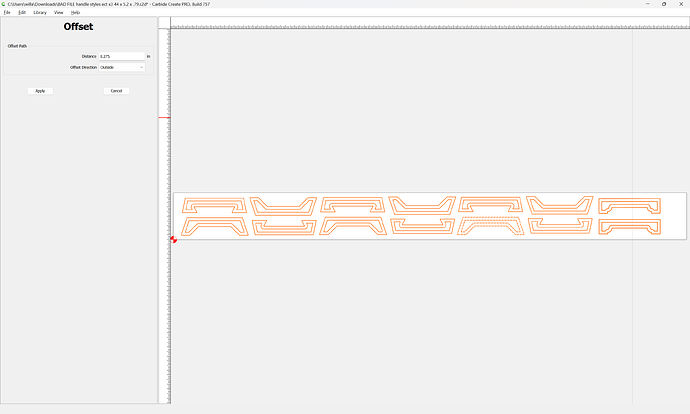

i think this is a file that you can see the issue

BAD FILE handle styles ect x3 44 x 5.2 x .79.c2d (196 KB)

sorry first time posting a file

You are cutting a slot to a depth greater than the length of the cutting flutes:

Offset to the outside by endmill diameter plus 10%:

and cut as a pocket down to tab height or the penultimate pass:

and modify the contour toolpath to start at the bottom:

Note that you need to ensure that workholding will hold the parts in place as they are cut out — if it won’t, add tabs.

I agree it’s a sketchy cut, leaving very little wood.

But I don’t see how that’s relevant to the fact that the machine cut the contours at 180° wrong from the simulation as well as pushing it to one side ? you can see it in the top pictures if you look closely.

Also, I greatly appreciate all that work you just did. Thank you.

I did notice the burn on my endmill now and will have to figure out how to fix that issue. I didn’t notice it till now do they sell and Mills with a longer fluted part?

I don’t think the machine reversed the cuts. I think what happened is the machine got bound up on the first cut on the right, lost steps, then finished that shape in the wrong position. Then it tried to cut the shape 2 to the left of that shape, and was off by the same amount.

OK that sounds about right could you help me to understand how to avoid this in the future?

Less aggressive cuts, and use Will’s solution to cut the outside profiles as a pocket rather than a slot.

Listen to your machine!!! I’m certain that it made some funky noises when it was losing steps.

After what you just taught me I believe this piece is the culprit but I’m not sure why this happened.

Could it be because I did not put tabs the piece let go and crashed into the bit and caused the missed steps?

That is possible causing lost steps when it was bouncing.

The info given previously is also to reduce engagement by cutting a pocket. The deeper the bit goes into the cut the sides of the bit drag causing heat. A pocket will help prevent that.

Rule of thumb is the depth of cut per path should only be half of the diameter of the cutter