Recently got a CNC (Shapeoko 5 )… Trying to make a .750 in pocket which i was successful (by digital calipers. Trying to make a .750in plug using the contour path and keep making .731 in plugs, not the .750 that I am trying to make. i am using a 1.7in thick piece of maple but only going down .6in into the wood The plug is very uniform in size just smaller than expected (using the recommended to path which was ~9 or so passes for the depth. Using a Shapeoko #201 bit (also used the same for the pocket)

What toolpath are you using? Are you leaving a roughing clearance and taking a finishing pass?

Post your .c2d file and a photo of how the cut is working out?

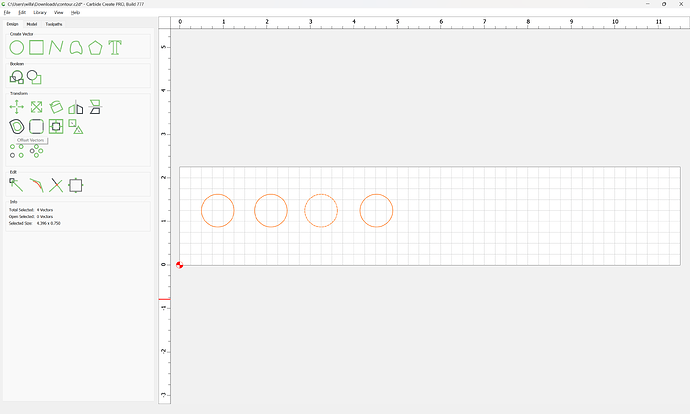

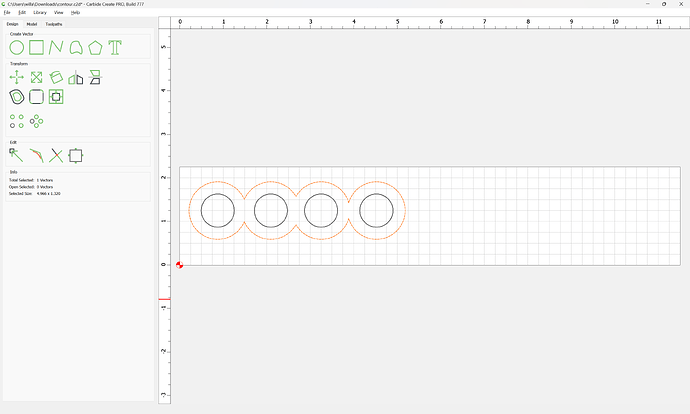

Thank you for offering to take a look . I was not roughing than finishing ( to my knowledge at least). Just straight cut

contour.c2d (48 KB)

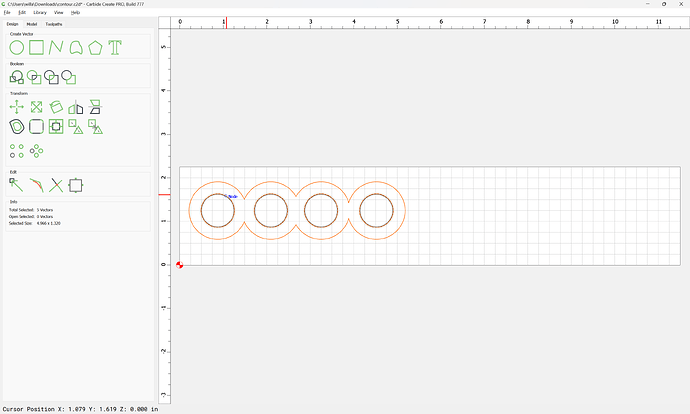

A contour toolpath cutting a slot almost equal to 3 times the diameter of the tool has very high tooling engagement and is likely to deflect/pull the machine into the cut.

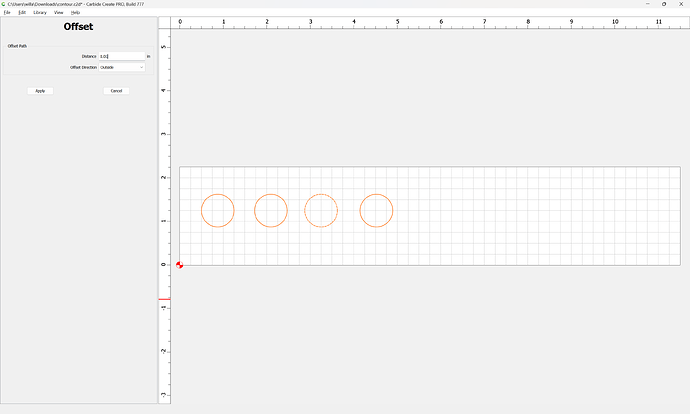

Instead, offset to the outside at least by the defect which you are seeing:

0.019 / 2 == 0.0095

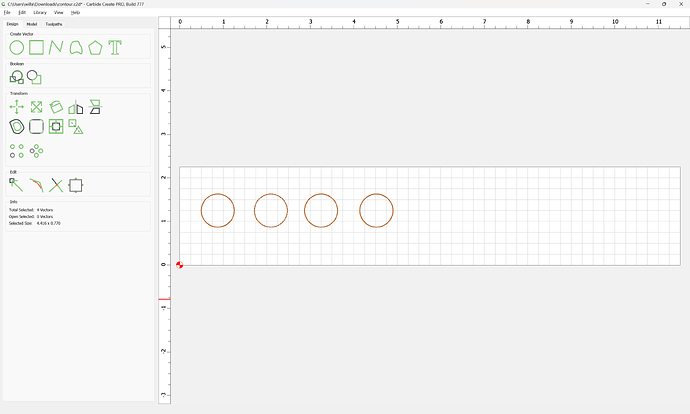

and then offset by tool diameter plus 10%:

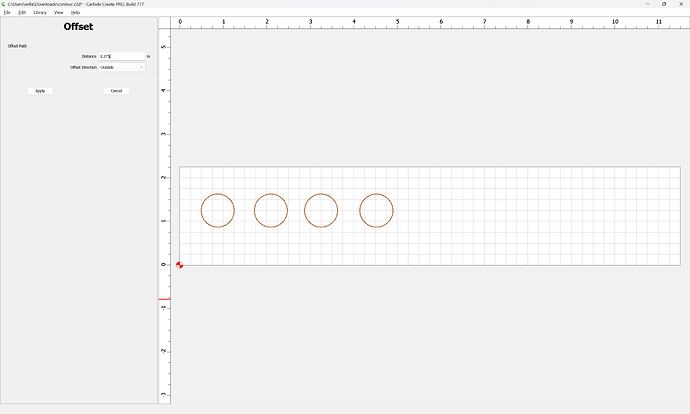

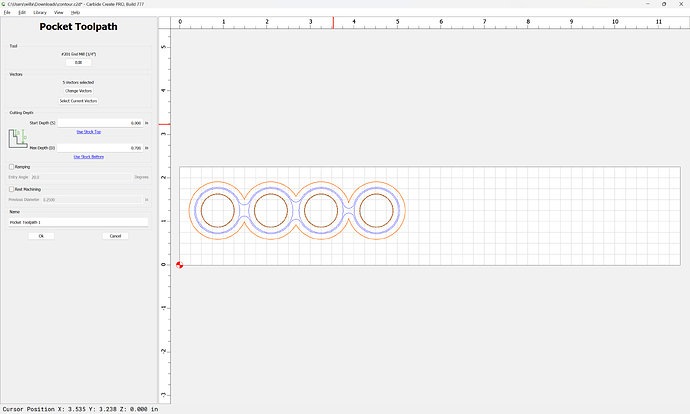

and cut as a pocket with the offset geometries:

and cut that, then measure the plugs — if they are oversize you can then disable the pocket toolpath and enable the contour and cut it — based on how that turns out you can then adjust the diameter of the geometry to get the desired fit.

Thank you. I thought that the ~9 passes would help with the tool engagement, but maybe not i do appreciate you explication and recommended steps as it seems like a better overall strategy for the future in most settings anyway. I will give it a shot and report back

again, really apricate your time on this

thank you again for your help. it took far more trial and error than i would have guessed. i would guess that the 5pro frame would be stiff enough so i would assume that the bit is where i am getting the less than desirable accuracy. I have not tried to cut a very thin version of the plug to see if that would increase accuracy or use a thicker bit. 2 things that i will try in the future. I think the part that surprised me the most was cutting the .7in in 8 steps and cutting .1, 0.05 then 0.02 at the end still needed some fudge factor to be accurate

anyway, more to learn for sure

Thank you

Try changing the direction to Climb. Now the cutter is trying to pull away from the part rather than into it. ![]()

If it’s bit oversize run the path again.

Thank you for the tip. Actually my last .1,0.05, 0.02 were all set as climb cuts

Tool deflection is something that many newbies don’t think about. The smaller the bit diameter, the more deflection a person can get in a cut, depending on the type of cut. Its always better to make the geometry bigger, and then adjusting as needed to bring into size when making cuts on the outside. Better yet it would be better to go with a bigger diameter tool to have more rigidity, thus producing more accurate cuts.

You will get it. You are doing the right thing by asking questions here and trial and error.

Used a 1/2 bit and indeed got better results. I offset 0.1 in for the first pass down to 0.6in then just a finishing pass to baseline. The diameter was .748in. Much closer for sure, but lots of waste.

Thanks to all that responded. Think I have solutions and a better understanding of accuracy

This topic was automatically closed after 30 days. New replies are no longer allowed.