Hi everybody, I am quite new on Carbide Create and I don’t know how I should draw and toolpath my pen holder. Here is an image of my (very simple) project… Many thanks for your help.

J-L

Hi everybody, I am quite new on Carbide Create and I don’t know how I should draw and toolpath my pen holder. Here is an image of my (very simple) project… Many thanks for your help.

J-L

Draw up the geometry from overhead, but first draw the pockets wider than the stock:

Then dupe those and modify the duplicates to show the desired top view:

Model the rectangle:

Select the two long geometries for the channels:

Subtract them:

Then select the geometry for the top profile:

Force it to be 1" thick using Merge Type: Equal:

Apply:

Show 3D:

A big Thank You William… I will try this asap. I will let you know if I correctly manage it.

Question: is there a way to learn these tips or it’s only a try and error process ?

There are many tutorials available on three Carbide website, YouTube, etc., but yes, it’s mostly trial and error.

Modeling in 3D is a learned skill that boils down to thinking about the “primitive” shapes and how to modify them to create your design. Once you see how a similar design works, you’ll be able to apply it to your designs.

The easiest way to make this is with a Bowl Bit.

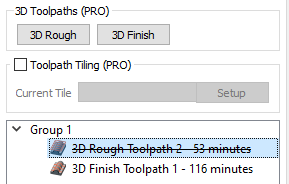

So I successfuly created my design in Carbide Create but, for some reason I do not understand, the 3D finish did not provide the smooth expected result. I am scratching my head ![]()

If some of you could give me a hint… Thank you

It’s most likely the bit choices and their F&S for the roughing and finishing passes. Honestly, it doesn’t appear like a finishing pass was made on the workpiece.

Can you post the bit selections and the F&S that were used?

Post the .c2d file?

What size tooling was used for the final finishing pass?

How does this compare to the 3D preview?

you need to create the finish toolpath as well. for real fine finish you want to set the stepover to <5% of the diameter of the bit.

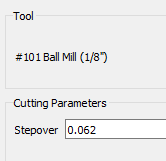

I used the 1/4 ball nose (nomad tools #202 .250) for the rough and the 1/8 ball nose (nomad tool #101 .125) for the finishing… All provided with the starter kit from Carbide 3D when I bought the machine…

The .c2d file is attached…

Test - 3D - Pen Box 2.c2d (128 KB)

ok yeah your stepover is half (50%) the diameter of the bit, which is what’s giving you the scalloped appearance

add a zero in there and it’ll be nice and smooth. but realistically for this I’d do the finishing toolpath with the 1/4" bit as well and a 0.0125 stepover or something, just depends how smooth you want it.

Thank you Dooryard… My mistake is to trust the default values ![]()

So the rule of thumb is 10% or less (until 55) of the bit diameter…

Will try that asap and let you know the results…

Thank you for the help… I’m learning a lot…

I had to reference this post the other day from @wmoy to remind myself for what I’m working on, he’s a smart cookie

Dooryard, it worked perfectly and the result is better than expected… Thank you again guys, you are amazing…

Here is the finished product with one coat of Basin Oil…

I can’t believe I got this result at the first attempt…

Chears !

This topic was automatically closed after 30 days. New replies are no longer allowed.