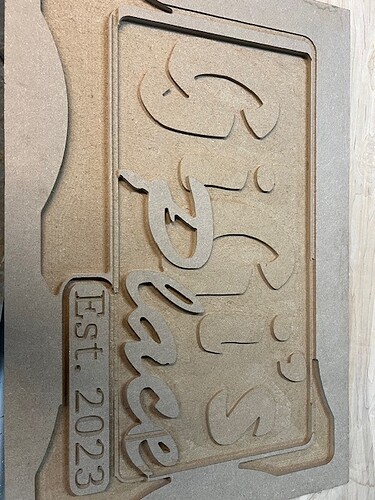

I sat and watched this thing run for 9 hours today, which is another discussion in itself. And 30 minutes from being finished, on my “cleanout” toolpath, it decides to plow through the middle of the “E” in “Place”. This certainly didn’t show up in the simulation. And while we’re at it, can somebody look at my files and tell me how to reduce the run time on this thing? Pics and files are attached. Thanks.

GiGis Place final TP.c2d (2.0 MB)

What was the retract height?

What was the last toolpath?

Is it possible the tool pulled out of the collet?

Post the .c2d file and details on how you secured the stock?

First off, I see you are using 1/8 end mill for the first two toolpaths. Step up to 1/4 and time will shorten by at least half. Neat design.

I think the retract height was .300. Whatever it was, it worked perfectly for 8+ hours. The bit didn’t slip. It was cutting the correct depth. It just shouldn’t have cut across the text like that. The text was finished. The toolpath that screwed up was using a 1/4" bit. I couldn’t use a 1/4 on the text tool path. Too many sharp corners in the text. The LAST toolpath would have been the contour to cut out the shape. The one that went bad was the one I drew to use a 1/4" bit cut out some of the pocket around the text to save time. Stock was secured with the 4 green clamps that came with the machine and did not move. This is some kind of software deal guys. It’s like the whole toolpath was cutting too far to the left. I let it make an extra round since the job was ruined anyway and it cut through the E again, but a 1/2" further left.

GiGis Place 4.c2d (2.0 MB)

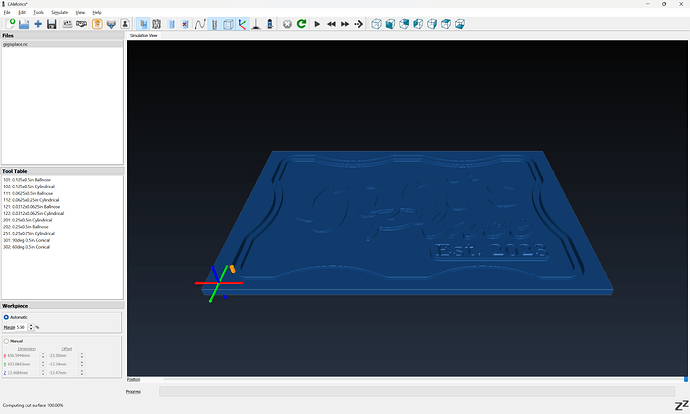

A 3D preview of the G-code doesn’t show any problems:

My suspicion is that the Z-axis got pulled into the cut causing lost steps, or the machine lost steps while trying to retract.

The Z never moved. The bit was moving left to right in a straight line and just made an abrupt 90 degree turn north an inch or so before it should have.

In that case, steps were lost along another axis.

If you haven’t reset XY or re initialized the machine have it go to current XY and see if that matches where it started.

I will check that. In the meantime I have completely redrawn the whole sign. Got the run time down. Will give it a go today. If the X-Y did move, what caused it? I must say, so far, that both Carbide Create and Carbide Motion have been a bit of a disappointment.

I had this happen recently while working with MDF, too, but I never figured out why.

Could this be caused by static build up?

Or should I set the retract height much higher? Just trying to figure out how to make the machine work better so I don’t lose work and material.

First of all, nice sign design, and sorry this happened.

This sure feels like a mechanical (not software) issue. If you haven’t checked this yet, my money is on a loose grub screw on the X stepper pulley, causing the shaft to slip inside the pulley, unfortunately right at the end of your long job. Loose pulley grub screws are a common issue reported in these forums, causing issues similar to yours. I don’t have a Pro, so I don’t know if there are “flats” on the motor shafts. If there are, one of the grub screws should be aligned and tight on the flat.

Did you export the NC file and check that independently ? Just to confirm the Tool path outside of CC.

I don’t have CCPro and my machine is running so I can’t export it.

It turns out you were close. This morning I went to initialize the machine and the X wouldn’t move. Just made an ugly noise. After a few minutes I found the the X belt had lost most of its tension and the pulley was slipping. I did check the set screws while I has the motor off. They were tight. Ran the job again today on actual wood (yesterday was a test run on MDF) and it did well up until the last toolpath when the machine “lost connection” 30 minutes from being finished. I will try to rerun that tool path in the morning. Thanks for all of the advice !

I’m happy you worked it out! At the end of the day, issues like this (endmill plowing a crazy path) are always mechanical-related (not software related). “Lost Connection” is another matter entirely, and there are lots of threads and advice on solving ESD-related issues.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.