Some notes on this at:

— may need to sandwich it in-between two sacrificial layers of a more rigid and more easily cut material.

EDIT: These were:

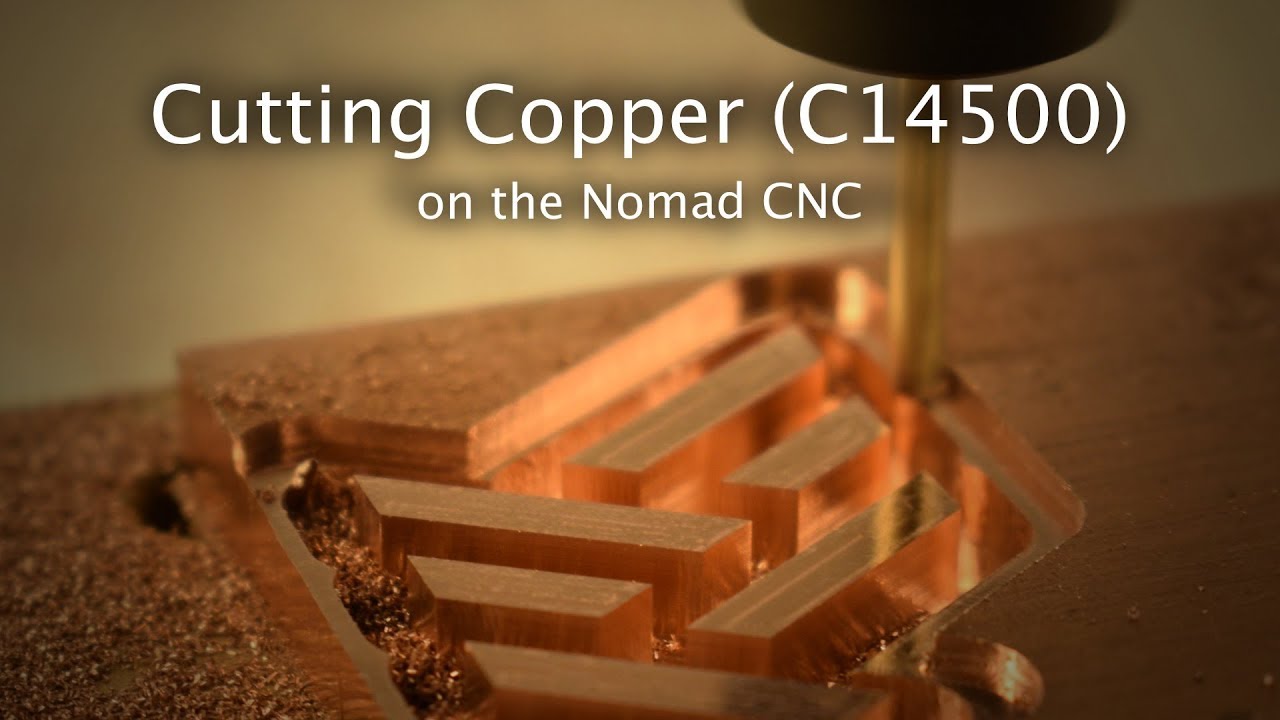

Use very sharp cutters with copper. Many alloys (and the element itself) are “gummy” and difficult to machine.

3-4 IPM 0.015 cut depth at the low end of the DW611’s speed range with lubricant — Copper sign

- Speed: 10

- Depth Increment: 0.015"

Ascertain that if a copper alloy, it does not contain beryllium.[142] (Note that such alloys are normally only used for non-sparking tools for certain industries.[143])

Nomad: “For brass and copper I use Plunge rate 170 m/m , Feedrate 400 m/m or more 10% / 20% and depth 0.07 mm. whit 0.063” cutter . And I use Alcohol for coolant to and the cuts are better ."[144]

1/16" carbide flat with DOC 0.07mm. Feed 400 mm/min Plunge 170 mm/min RPM 19000 and coolant Trichloroethane whit good ventilation. [145]

Horsepower Unit Factor (Copper)

0.50