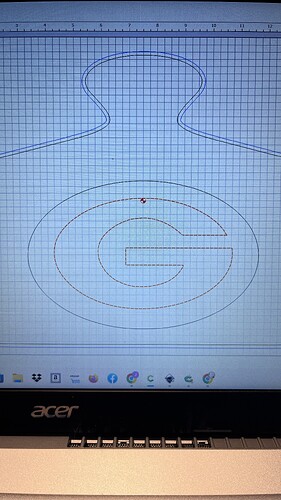

Here I am again. Basic question about toolpaths. I am attaching a pic but my goal is to pocket out the space around the G within the outer circle. So the G stays the height of the board and there is a pocket area to fill with epoxy around the G. I may be choosing the wrong tool path but whatever I choose makes a pocket of either the entire board or the G. How do I get the area around the G cut out?

Solved!! This community is wonderful! Thank you.

I do have one more question. Do you have a suggestions on the max depth for me to use if I am pouring epoxy? And when I say I am new. I am new new. My first toolpath is to cut out the board. I did that in a contour toolpath and thought i would use 1/4” end mill. Do I need do switch bits for the pocketing?

Could you give bit suggestions?

It is taking a lot of time. My stock is walnut .931” thick. It is saying cutting out board is 302 min and G pocket is 509 min. Is this normal or a long time?

Hello,

For the epoxy inlay, I typically go 1/8" to 1/4" depth. I would suggest doing the outside contour as your last step in case the tabs break and the piece shifts on you. The minutes for cutting sounds extremely high! A 1/4" end mill should be fine depending on the size of the G pocket. If you have a v-bit, you can also use the advanced V-Carve and select the pocketing check box. This way will give you nice clean lines to work with. What feeds and speeds have you selected with your 1/4" end mill? Those values will dictate the length of time for the cutouts which I am sure we can reduce drastically.

Are you going to color the epoxy? If so, and the color is dense, you dont need to make the pocket that deep - like 1/4" or less.

Your times do sound a bit long, if you can post the CC file you are working with perhaps there’s something we can point out that will speed things up.

If you have experience with this, I want to go with whatever you suggest. The advanced vcarve sounds good. Hope I can do that toolpath setup.

I’m sorry but where do I go to find my feeds and speeds?

And I wanted to ask about tabs? I thought I would only use them if I was cutting letters out?

I am attaching my file here. I changed a few things. I changed to advanced vcarve at .25 max depth to put epoxy in. The contour of cutting the entire board out is what I need help with…it takes way too long. Please give advice.

The vcarve is much less time.

Contour:

Step over : .118

Depth per pass: .006

Plunge: 10

Feed : 24

Rpm: 18000

G cutting board.c2d (676 KB)

I am NEW NEW too so I appreciate your questions!

I’m not on my computer but I’m assuming you helped so thank you so much! I am leaning. Now if I could figure out my name cutouts. But I’m getting there thanks to people like you!!

I’m sure I will keep asking new new questions to help you out. Ha.

Me too! I’ve asked a bunch of questions and everyone here is sooo helpful! I hope one day to be able to contribute too!

You might also consider using a bandsaw to cut out the board. As much as it’s pretty cool to use your machine for everything, sometimes it’s easier and faster to use other tools.

On top of that, a bandsaw allows one the option of resawing stock (you can use the machine as a router sled to smooth and joint stock) which can afford one the option of using less expensive rough cut stock, and of doing book matching and so forth.

A wonderfully talented cabinetmaker I knew when I was younger (my great aunt’s bridge partner’s husband) had a bandsaw as the only powered tool in his shop.

Wow! Yes, I am thankful for you. I am going to look at what you changed so I will learn from it! I hope I am the one giving advice one day. Thank you so much!

Has anyone mentioned to you that you might want to use a clear coat around the area you are filling with epoxy to deter bleeding into the wood? Try a couple of light coats before the fill and any over-spray onto the surface can easily be sanded off.

Good point ! Do not forget to protect your wood with a thin coat of clear epoxy. If not, the color in your epoxy will penetrate the wood grain and it will look bad…

I have used shellac for that and had good luck at least on walnut. It dries fast so no long wait.