How critical is dust collection? Well I’d say critical enough that you need a new controller. Also, wood chips and particles can be statically charged. If it lands on your controller: ZAP. Regarding the dust and chips, they can clog lead screws in the Z axis, get between belts, jam V wheels. While all of that is critical, nothing as critical as your health. There is no more dangerous dust particle than the one you don’t see that ends up in your lungs. All of this can be avoided with a cheap $60 Rigid shop vac, or one that is portable enough to place conveniently near the machine.

A couple of rope/wire placed along the hose works. I just played with it until the hose would fold up and move out of the way without entangling. Two hangers points seemed to be the trick.

I found the stiff arm caused constraint issues ( at least for me ).

I know this example does not have height limits but the concept may still work.

Post some pics when you’ve built it along with some comments on how well it works please.

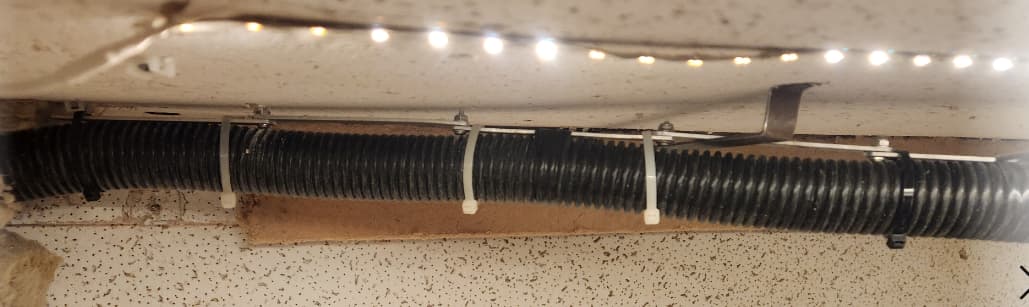

I have my dust hose run along my Z axis drag chain and for a while it ran along the X drag chain as well, I put much larger drag chain on the X for the spindle power and hoses, air line etc. and that’s chunky enough to strap the antistatic hose to.

I’m working on it. I just bought some Johns Manville SAFB insulation to sound proof it a little more. When I get it working I’ll start a new thread so It’ll be easier to find later on.

Something I have not seen mention in this topic is the fire risk of improper dust collection. Sawdust is super flammable especially if airborne. Airborne sawdust can actually explode. If something happens and your endmill starts rubbing instead of cutting it can build up enough heat to cause a fire which can quickly get out of control if there is a large amount of sawdust nearby.

My late brother was a full time wood worker from age 18 till his death at 63 years old. He passed because of liver disease but I always felt he had undiagnosed COPD. He had a permanent cough starting in his late twenties. I worked in his shops on and off my whole life. We were in a redwood phase for several years mfg’ing greenhouses. Developed staph infections in my nose. I’m back to making redwood furniture now and the minute it hits my nose I’m a train wreck. I’m constantly improving my dust collection. Can’t get enough of it.

The cabinet pic you posted is cool. Maybe?, you could cut a narrow slot in the back the width of the bed, and who’s height is couple inches above the bed. Cut an inlet grill same position on the door, put a vacuum plenum on the back. Your fine particulates would get picked up in the crossfire. I built a cardboard structure on my 3XL and it work well. I use a WEN 660cfm extractor that connects to a Oneida cyclone. In fact, your cabinet has inspired me to build a permanent cabinet with a door.

I’ve made progress. Haven’t tried it out with an actual cut, but it looks promising. I made a ‘chain’ out of 1" x 1/8" by 5 links and used #6 hardware as the pivot. There is a lsider to keep the hose up also:

I have a rockler dust mate expandable vacuum hose, that I cut about 5" off and used it’s swivel adapter which fit in the dust pickup. I made a 1/8" aluminum plate that mounts under the Z stepper and it has a 1-1/2" emt adapter. I cobbled together an elbow with a nipple that goes down in that adapter.

It still has to get prettied up, but this is my test.

BTW I also added 1-1/2" Johns Manville SAFB sound insulation to the sides and on top of the enclosure. I think it will be down in th 60 DB range - sweet.

One more photo:

You can also see my expensive plastic organizer, they cost $15 to $20 each, but come filled with great Chinese food lol

Holy Moses, a 300 lb fitting. Turned a few of them through the years

Yeah, but it was free, came out of the junk box.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.