In order to deal with deflection from tooling running harder is the incorporate a finishing pass at the end so you can remove tool deflection and hold tighter tolerances when finishing cuts. I use endmills as small as .0325 inches. I have to be considerate of the tool pressure on this smaller tool so I don’t break them. The smallest tool I had ever used was .015" drill and that was very tough to keep from breaking if fed too fast or even touched off too hard.

Are you cutting the entire 3.75?

Yes but no. I can not cut straight down 3.5" I use the Cadence Extended Jenny to get 2" down.

This is actually my next challenge. Contour down 2", flip and repeat the other side.

And be repeatable.

I do step down to 3.5" so long as the collision detection allows in Fusion. It will start stepping away from the part.

I’m also afraid of cutting metal… jk

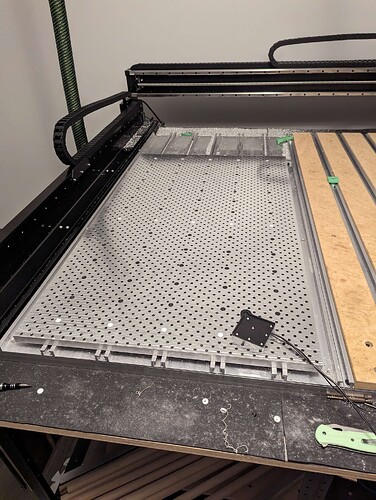

Saunders plates are cute but how about a 50lb slab of 6061 21andsome x 36 all machined using CC. (DONT DO THIS SERIOUSLY JUST LEARN FUSION AND BUY SMW)

Some things I learned

Your time is infinitely more valuable than hand finishing a large project and essentially paying yourself 2$ an hour.

1/8 Tools can do about 50x spiral entry holes to 3xDia before breaking without pre-through-drills which you cant do without center drills. This creates exponential time increase.

Cutting fluid is nice but if you can’t get enough you’re basically spitting on it and if you have air blast you cant just spray it you will need to set up a misting system.

Tapping 2315 holes will turn you crazy. Buy a tapping arm because even a threadmill will need a de-galling in Lye every 200ish holes.

The effort it takes to trick CC is better spent learning to read Gcode and then a CAD program finding a post processor, setting that up, setting up your machine, making some ghost files to make sure you understand your post is good, then learning feeds and speeds, then testing those feeds and speeds gradually getting more and more ballsy.

Or you can do something like this and your programs will take forever and be inefficient, wear your tools prematurely, battle CC’s bullsh where it sees a line and refuses to contour it because geometry bad. (hence the 6th side of this program being done separate)

mitee bite .31.c2d (72 KB)

And finally: 2315 of anything is a bad time. Because 2 seconds per op is an hour let alone minutes per op

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.