Hi. I’m looking at making some boxes and other items down the road. So far I’ve only seen people make thin things like signs, and trays? Has anyone made something deep or tall?

This is a function of:

- part geometry

- tool geometry

- workholding

and one has to plan things out so that dust collection won’t interfere.

If you’ll try drawing something up, and then visualizing it relative to the machine structure you should be able to get a feel for how things will work out, then make a test cut.

I am working with 3.75 thick pine. I think 4.25 is MAX under the ZAxis holder

I haven’t ran anything tall or thick yet, but I have just finished making the blocks that will raise my gantry up 2 inches. I have a clearance of 4.25 inches right now, but as soon as I am able to add these blocks, my gantry will be raised to 6.25 inches. My plan is to also be able to add an opening on the table to install a rotary platform to allow multiple angle jobs, or full form carving. All still in the design stages for the table design, but the gantry blocks have been cut today and drilled, but I am concerned that the holes are not the right size. I didn’t measure the bolts but I will figure it out.

As Eli eludes to, it’s also a function of the gantry clearance & the Z range of motion.

You can move the spindle/router up to accommodate a longer tool, but you have to be mindful of the tool clearance as well.

And making sure your Sweepy doesn’t hit something !

I have found on thick stock and deep features the Sweepy comes into play.

Are you using aluminum square pipes? if so where did you get them?

appreciate it.

Yes. You can double the Z height available to you if you flip the part and machine from both sides. If you said that your available Z height under the gantry and with your spindle installed was say… 75mm (3") you would potentially have 150mm (6") of machining space available when flipping the part.

As stated by @WillAdams, the geometry of the part and the tool plus your work-holding methods would impact your final decisions. Thin tools with large stick out values will not serve you well if machining accuracy and tool deflection are considered. One example is that people carve boxes with just their basic available gantry height. If you made a 150mm (6") deep box in two halves of equal proportions, divided at say 75mm (3") then you have a 150mm (6") deep box without creating difficulties and just using your current machining techniques

I am using aluminum square tubing, but not a conventional tubing for the bed rotary fixture. As for the aluminum that I am using the gantry blocks, it is solid bar aluminum, measuring 1" thick, 2" wide, and I cut them down to fit the Y axis plate where the gantry bolts down. I drilled clearance thru holes, but will have to buy longer bolts to accommodate the added blocks.

As for the rotary table fixture, I am still designing it with the idea of maybe using square tubing. I didn’t buy any of this material. I still do consulting work for the machine shop I used to work for and my old boss has given me the material because it was extra material after they built the display cases for a customer.

The gantry height clearance is 4.25 inches from the bottom of the Z axis plate. The Z axis raises higher, but clearance is determined by the Z axis bottom plate. Plus, if one adds the sweepy, or even the under mount sweepy, then the clearance is reduced further. I am installing aluminum spacer blocks at my gantry mount, which will increase the clearance to 6.25 inches. If I am able to fabricate the table for an area to have a rotary fixture, then I could potentially increase material clearance to 8.25 inches.

I will be dealing with deflection and tool clearance as well, but that is the nature of the beast when one increases height of the gantry. What I am hoping to have designed and built onto my table is an area that will accommodate a 4th axis add-on for my machine when one comes available or can find one that will work with my Shapeoko 5 Pro.

I have a 2.2kW spindle kit and a from PwnCNC, who make parts for many different machines. It arrived truly plug and play after sending an image of the controller board. Mains lead, spindle lead plus the PWM attachment lead.

The V7 dust boot can be attached at any height on the spindle and does not impinge too much. My maximum available Z axis height is measured from the baseboard to the collet nut.

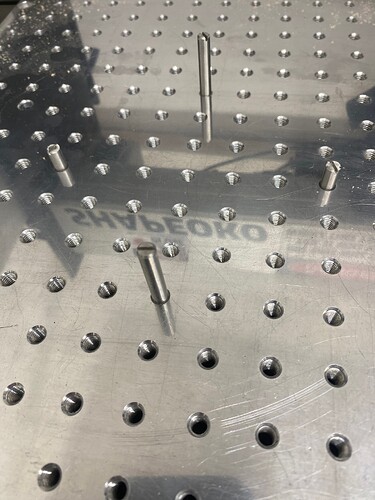

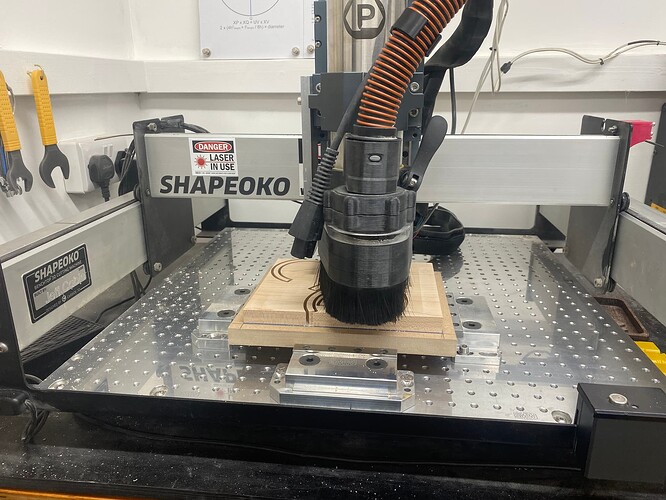

PwnCNC is truly machine agnostic and they create items that are tested to work with several different CNC machine manufacturers. My machine is a belt-driven Shapeoko 3 dating to July 2020. My modifications include the Carbide 3D HDZ heavy Z axis, a belt adjustment system that permits me to tune the belts to a set frequency (C3 ~ 130.813Hz) and a Saunders Machine Works baseboard with 840 x M6 threaded holes plus their stiffener bars and modular vice system. I can reliably machine metal to a tolerance of ±0.001" and on one occasion achieved an unbelievable tolerance for my much-improved machine of ±0.0004".

My machine is a standard size so I only have a work envelope of 400 x 400mm but if I had another sized machine and space to put it, I would also want the Masso controller and the ATC provided by PwnCNC.

pix:

Sounds great. Thanks for the response

I’m just using wood. I’m not brave enough for metal yet.

I’m on wood only so far.

Oblig video to watch by the amazing @DennisVanHoof

The only issue I’ve had is when i tried to cut 3.5 in tall stock. I clamped it from the side (fairly low) so it pulled the material into the bit. Lesson learned, make SURE stock is held down firmly. Probably would have been a good idea to clamp it from the top, but you live and learn. ![]()

If your stock is a little long, or the edges won’t show, you can cut a groove in the side or end with a table saw, I usually go about 1/2 up from the table & use that groove to clamp the block.

I have had good luck with the compact Tiger claw clamps.

Anything pushing at the edges of the machine bounds is going to present some unique problems…ask me how I know…

Many in this discussion will enjoy our next video. The stock begins at 88"x40"x3.25"

Challenges were encountered…

I cut plywood up to 1 inch thick, and also did some pieces of 2inches. The depth of the cut IMHO mostly depends on the cutting length of the tool, and I rarely get a hold a bit that long, usually have them made, and every time get a call from Dinosaw warning me that bit might break. And it does. I am also afraid that thinner bits -if they do not break- bend during the cut and therefore are by far not that precise.