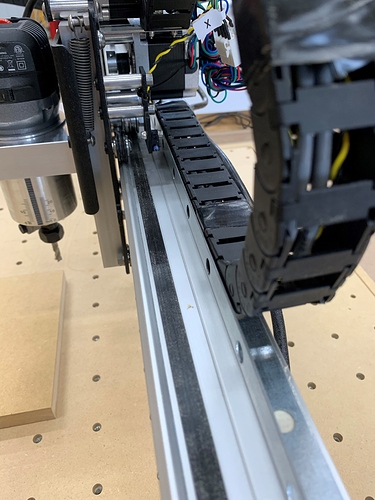

I used electric tape for the router power cord and a metal angle to keep the drag chain away from the screws. I also used heavy duty double sided tape to secure the chain end near the control box.

I tried to square my XL for about a week taking it apart and reassembling it, the only thing that i was able to do to fix it was to add .020 of shims to the ends of the Gantry rail on each end. i found this from the tutorial that Julien had taken time to provide. i think it is called Introduction to Shapeoko CNC A-Z. this shows where to place the shim materials and i no longer have any gap in either the front or the rear on the Y axis. the tutorial is worth a good look.

(FYI, this is what @Tail-wagging-the-dog is referring to)

That does 2 things - (1) gets rid of the gap & (2) can cause the machine to create ellipses instead of circles since X and Y are not perpendicular. Better to shim the X extrusion after the frame is squares. Truly better is to cut the extrusions square; how much more could it really cost build a fixture to make accurate cuts.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.