I really like it so far, more so than I expected, wish I’d bought a heavier vice earlier. Having square & flat face, top and sides on the fixed jaw to line things up on makes life so much easier. Cutting sounds completely different too as the clamping force is pretty good and the vice is 10kg on it’s own (22lbs). I’ve also already started zeroing on the fixed jaw face and side before even loading the workpiece.

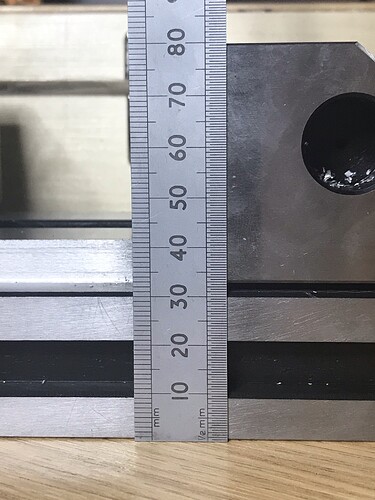

As I’m sure many others have before me, I spent ages looking for something that would fit under the Z carriage (HDZ for me) but give me a proper set of square and flat surfaces to clamp with. The only vices short enough I found were toolmakers vices, this one is only 80mm (3.15") high total with 40mm (1.57") jaw depth

It clears the bottom of the HDZ by about 10mm on my current spoilboard, Jaws are 90mm (3.5") wide with a 120mm (4.7") opening and it’s a pin vice which pulls the moving jaw down as it clamps. No big handle sticking out is nice although I’m still getting used to the pin mechanism.

There’s enough Z travel on the HDZ that I’ve not been limited so far, I bored holes through that 4040 extrusion in the pic above with it clamped in the vice without problems, I am careful to set small retract heights in the Fusion CAM though. I am also being careful to think before using the rapid positions and send the Z axis up to be safe.

I realised just before buying that most of the Chinese imports seem to have a row of holes down the side but this one I found at a local supplier

https://www.arceurotrade.co.uk/Catalogue/Workholding/Machine-Vices/Precision-Tool-Vices-Type-2

has slots down the side instead which I preferred. The fixed jaw face, sides top and back are as flat and square as I can usefully measure which surprised me for the very fair price. This supplier actually seems to do some QA on their stuff, it’s not the first surprisingly decent item I’ve had from them.

I plan to mill a slot in a section of spoilboard to recess the vice to get a bit more height clearance but I’ve not yet run out of travel on the HDZ and my spindle is low enough to put the standard Carbide3D 1/8" cutter straight through the spoilboard.

Does that help at all?