I have an answer, but let me qualify my answer first. Carbide Create does not (currently) support doing anything related to the “taper” part of that bit. Therefore it does not “need” to know the angle, but isn’t it interesting that Carbide 3D has a place to display the angle. I’m assuming (just my guess) that they are leaving the door open to venture down that path, and this allows them to do so without having to worry about data conversion of tool libraries in the future.

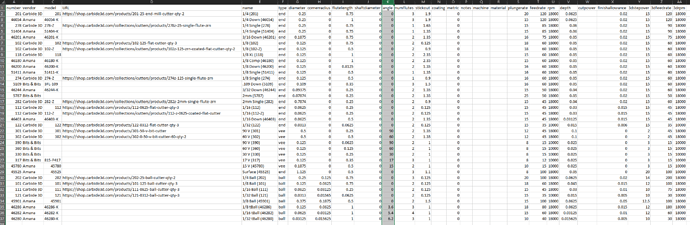

Now for the real answer, so they left a place in their tool library for the angle, but the actual software interface does not allow you to enter it. Behind the software, the tool library is actually a comma delimited file. Once you find the file there are a couple interesting things you can do.

- You can edit everything, using Microsoft Excel or really anything that can edit the text (ASCII) comma delimited file (see picture below). So I added the angle values, which (currently) have no use but it calms my OCD monster.

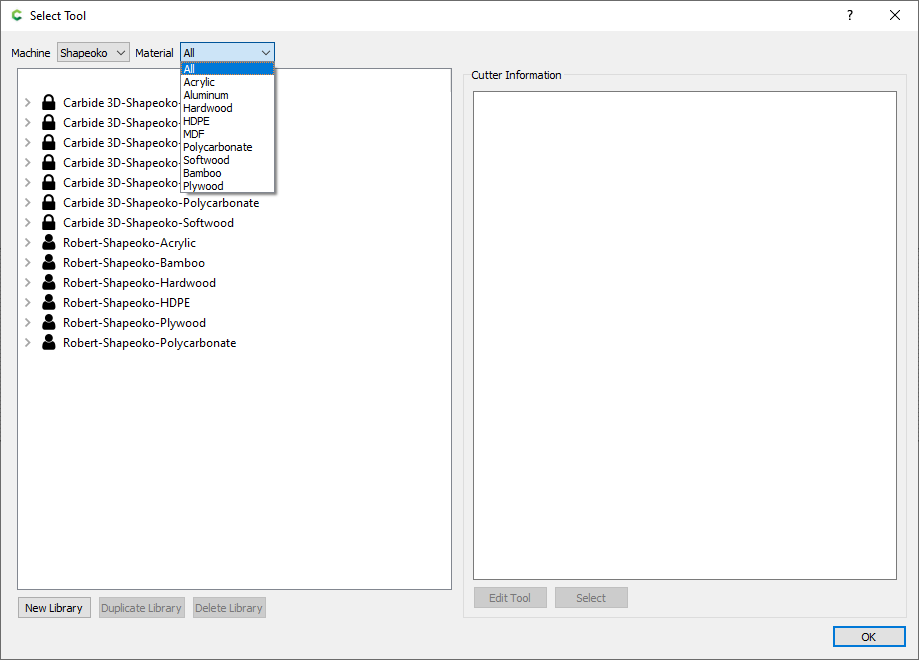

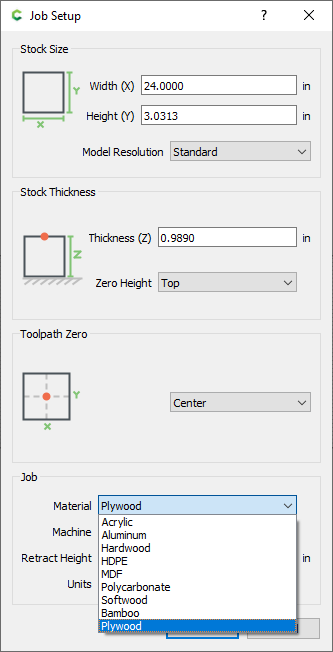

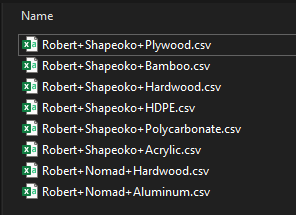

- If you look at the file names of these CSV files, the names themselves drive the software. So if you have a material that you work with a lot, for me Bamboo and Plywood. I made files with those names and look at what happens… I now have that material listed as an option, which lets me dial in speeds for those specific types of wood.

Probably more info than you were wanting, but I thought might be useful.

(Additional Thought) Don’t be too concerned about the taper and Carbide Create not supporting that geometry. You will be able to push those tapered bits faster (than straight ball nose), which is a lesson I just learned while working on my second topographic map. You will be able to carve VERY fine details with that Amana 1/32 tapered ball nose, the only downside that my rookie-brain can think of is if you wanted to make deep 1/32 slots, the resulting walls won’t be a perfect 90, but (a) I think that kind of cut would be rather rare (and strange) and (b) visually I don’t think anyone would be able to tell.