I am in Southern AZ. It’s hot and dry. I have a basic workbench w/ inset router and my CNC cabinet next to it (same level). I have a little Rigid and Dust deputy going to 4 gates.

Lately I’ve been doing a lot of plastics like acrylic and at times had EMI disconnects. This week I started to try my first tray. It was some remnant at the local woodworkers source that was about 1.75” thick. My machine wouldn’t run more than 20 seconds before disconnecting. So I spent a couple hours searching and finding a few different posts. Here is what has worked for me (so far ![]() ).

).

I have a wire connected to the closest outlet’s ground using this device. (This is where lights and router are controlled with a light switch.)

https://www.amazon.com/gp/aw/d/B071J61CSV?psc=1&ref=ppx_pop_mob_b_asin_title

That is connected to the wire in my flexible air hose. Then at my Sweepy I ran aluminum tape and tapped the wire of the air hose to Sweey with some of it tapped on the inside to provide grounding to the router casing.

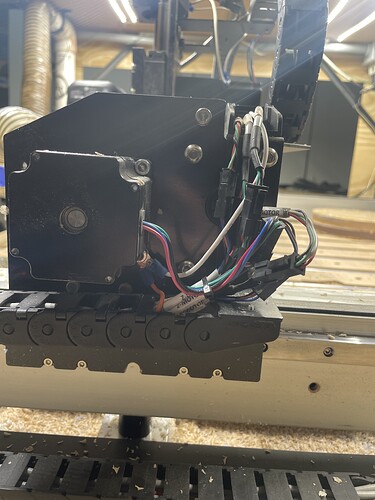

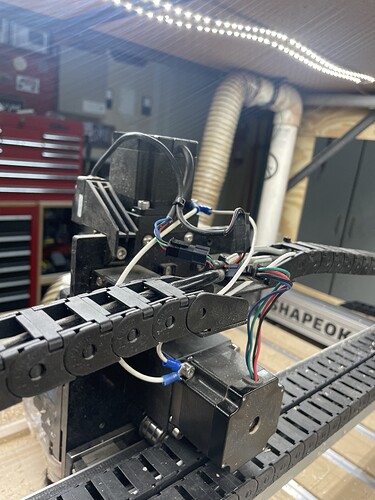

Prior to that one, I had connected ground to all three rails at the stepper motors and the ground near the controller.

I even ordered some kind of USB thing that I was going to connect before the tablet. But I don’t think I need that now.

The only question I have is, will I run the risk of frying my controller having the same chassis ground as the controller & stepper motors as the dust and router case?