I’m building a table for the CNC that is on lifts so I can raise it up to the garage ceiling when not in use. The lift has a 400lb limit, which sounds like a lot, but goes quick when building a bench out of 2x4 and plywood.

It would help if I knew how much the fully assembled 5 pro weighed so I can design it appropriately and as light as possible.

Here are the shipping weights, which should be just a bit more (packaging) than the machine weight.

4x4: 210#

4x2: 170#

2x2: 120#

What do you think? Subtract 20lbs of shipping weight for the 4x4?

I think it’s just some pretty heavy boxes. Not sure if there are wood spacers or internal packing material that would weight that much. Just guessing 10# of heavy cardboard. ??

I’d just go with the shipping weight to be safe.

I agree with @Tod1d, you might be asking for a disaster if you are trying to get an exact weight. Probably best to error on the safe side and leave in the weight of the packaging.

If I remember right my empty packaging boxes for the SO5Pro 4X4 weren’t all that heavy.

Don’t forget to add in your spindle/router and tools to the weight ;). Cool idea for storage. I am much less creative. Just got back from restore with two metal legs to screw into MDF ![]()

May i ask what the lift looks like?

Here’s the lift in action:

The platform is 6’x6’. The lifts can lift 100lbs each and combine to lift up to 400lbs.

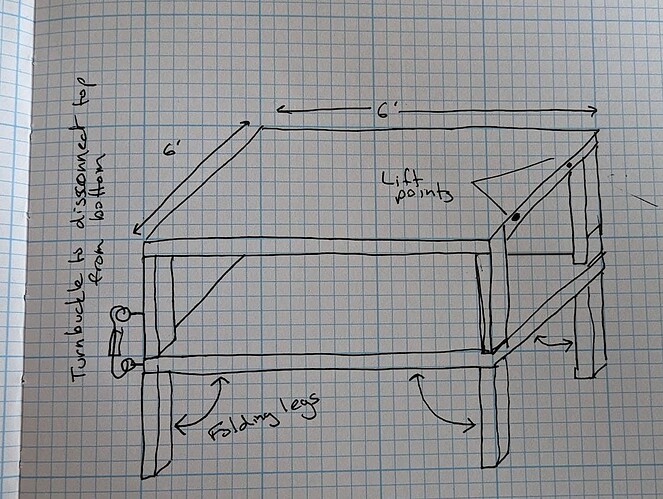

The original idea was to have that “top” platform with my 3d printer and soldering station. That would attach to a “lower” platform with turnbuckles. The lower platform would have the CNC. There will be folding legs underneath.

When I want to use the 3d printer or soldering station, just drop the lift, unfold the legs, and it’s ready. When I want to use the CNC, drop the lift, unfold the legs, disconnect the top platform from the lower platform and lift the top platform out of the way.

Pretty easy, except the weight!

You can see I experimented with 1/4" birch, which isn’t going to work.

I also tried aluminum square tubing, which isn’t going to work either.

Next experiment:

Steel 2"x1" to replace the aluminum tubes. And 1/2" plywood, but cut out the middle 4’x4’ section (which will just be under the CNC machine anyway and isn’t needed. Removing that 4’x4’ section of plywood will shave off 12lbs of weight and shouldn’t impact the benefit of the plywood holding the frame square.

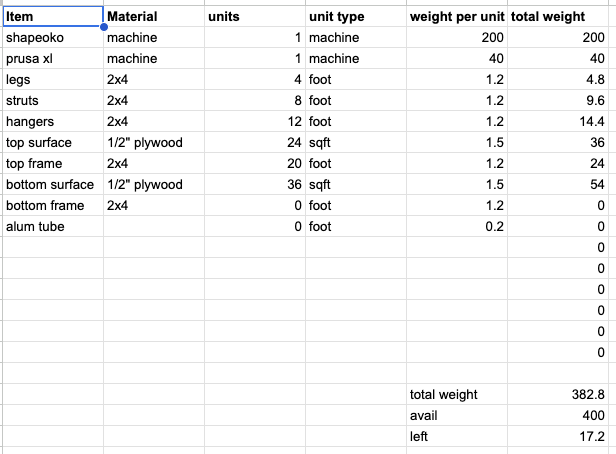

Here’s some estimates:

That is briliant.

What happen if tou find a beautiful piece of wood that weights 100lbs. Is there a support system while in its lowered state?

Yah - I’ll have foldout legs for stability once it’s down. The lift is only to get it up out of the way when not in use.

Again, brilliant idea. I often have thought about a gantry lift with an automated chain fall type setup.

Here’s a crude picture.

One thing not shown is that the folding legs actually unfold twice. Once so the table is at 37" when using the 3d printer or soldering. Then when I disconnect the top and lift it out of the way, the legs fold out again so that the CNC is at 37" off the floor.

I am confused…. How does someone have a cnc that is not in use?

Wait, this is about cnc’s?

![]()

This topic was automatically closed after 30 days. New replies are no longer allowed.