Anyone have advice on how to avoid plunge cuts when surfacing? I’m using a roughly 1-1/4" diameter surfacing bit and any time I create a pocketing toolpath to surface a board it goes straight to the middle and plunges. How can I make it enter from the side? Thanks

See:

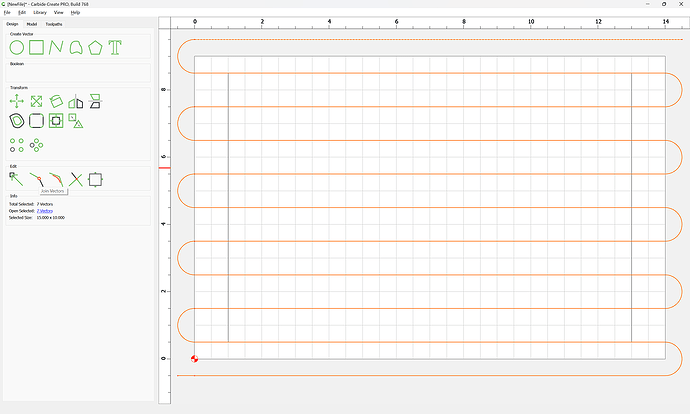

To echo @WillAdams I have had pretty good results setting up a linear array, Contour toolpath, no offset, stepover dependent on endmill and substrate. Here is a quick picture of what that toolpath looks like (from Will’s post). Welcome to the Forum!

This is how I do it as well. A couple things to note, I prefer climb cutting on the outer edges at least to avoid chip out. You can just mirror the vector to change the cut direction.

If you make an even number of passes it will climb cut both the first & last pass.

Absolutely, I forgot to mention climb/conventional milling… especially important on the outer edges. Thanks Tod!

Thanks all. Lots of ways to get it done. Of course it would be easiest if we had a surfacing toolpath type, or just more control over ramping at least. Starting with raw wood I find myself doing a lot of surfacing.

I think a zig-zag/lace/raster path option in pocket would cover it. Along with the climb/conventional option. A “Follow” pocket option would also be cool. The reverse of the current pocket going outside-in, rather than inside-out.

This topic was automatically closed after 30 days. New replies are no longer allowed.