WillAdams

August 19, 2023, 11:51pm

2

Box joints are one approach:

They require a vertical fixture though, and require a minimum of 3 setups:

cut parts to size and machine any internal features

clamp all four boards and machine joints into two corners

rotate the four boards 180 degrees and machine joints into the opposite two corners

They can turn out well though:

A traditional way to make boxes is to make them all of a piece, and then cut them apart — this can be made easier by cutting a slot, and cutting through at the corners, but this results in losing the width of the slot (or more when a saw is used to finish) in height.

Couldn’t resist picking up a JointMaker Pro when they were recently on sale at Bridge City Tool Works:

so have to try it for cutting apart a box:

[20230803_2121241]

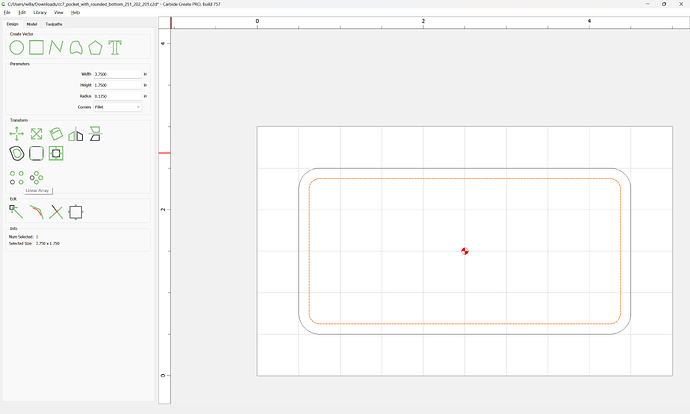

The big feature which makes laying these out easier is the Linear Array feature:

e.g., :

Arrange an overview of the parts:

[image]

Then draw in the geometry to cut out the front/back for the lid:

[image]

and Boolean subtract:

[image]

[image]

The bottom will be in a rabbet half the thickness of the board which is inset by half the thickness of the board:

[image]

and if need be, mirror them vertically to get the needed arrangement:

[image]

The space in-between those elements will be taken up by the joinery:

[image]

Divide its height by the number of joinery part pa…

I’ve been working on a full-blind miter box joint for a while — if you’d give me an example box size and stock thickness, and let me know what features you would like (rebate for lid/bottom? hinged lid?) we can walk through this with you here.