Unfortunately, Carbide Create doesn’t have step-and-repeat or distribute spacing or any features which would make this simple and automatic.

You can use the Align commands, but you need a row and a column of items properly spaced to start — easiest thing is to draw one column, dupe it, rotate it, drag it into alignment, dupe again, drag the duplicate over, then dupe the first column and drag it into alignment, repeating as many times as desired.

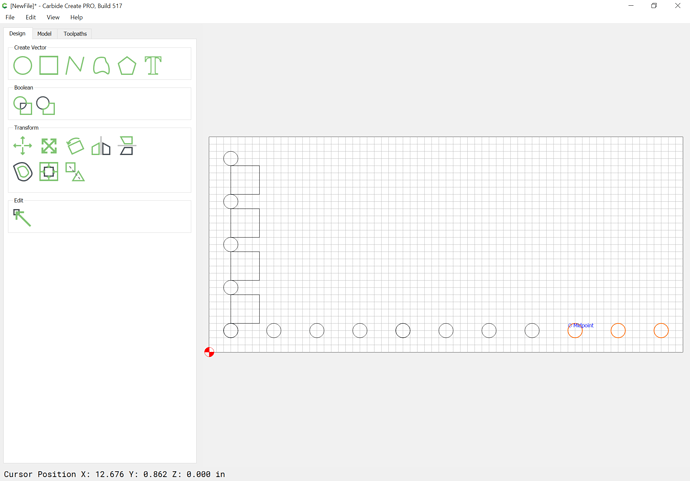

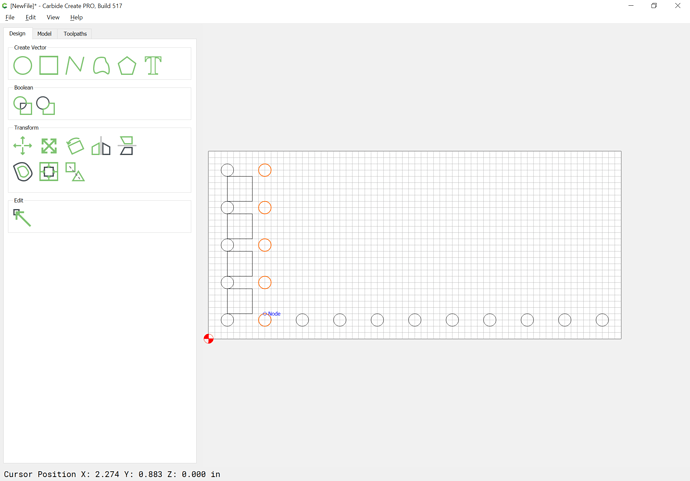

Here, assume one wants 1/2" diameter circles on 1" spacing:

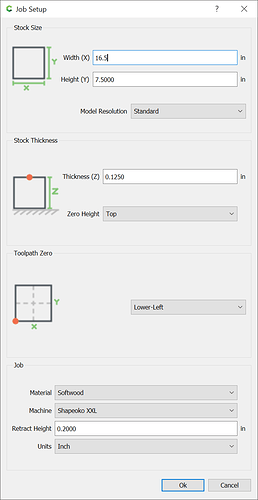

First, set up the document the correct size:

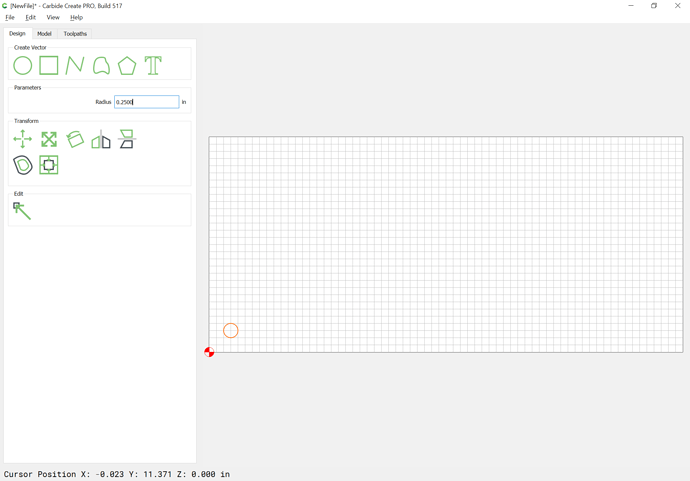

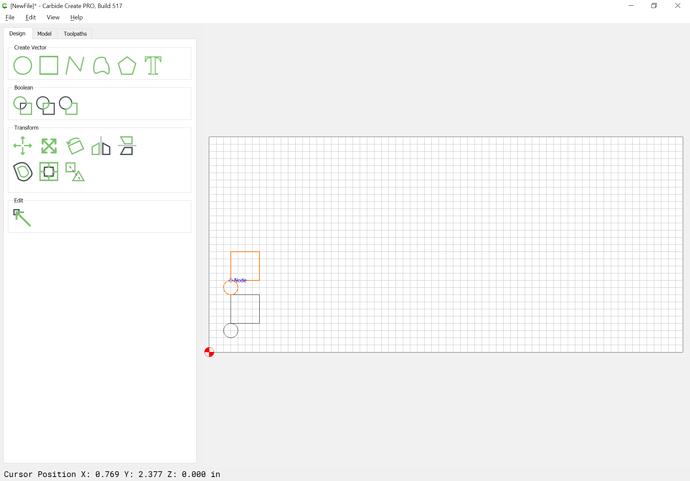

Then draw a circle:

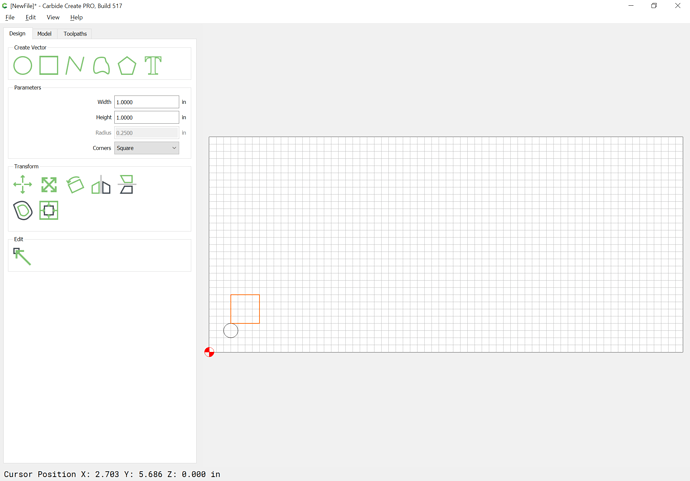

Then draw an object for the spacing:

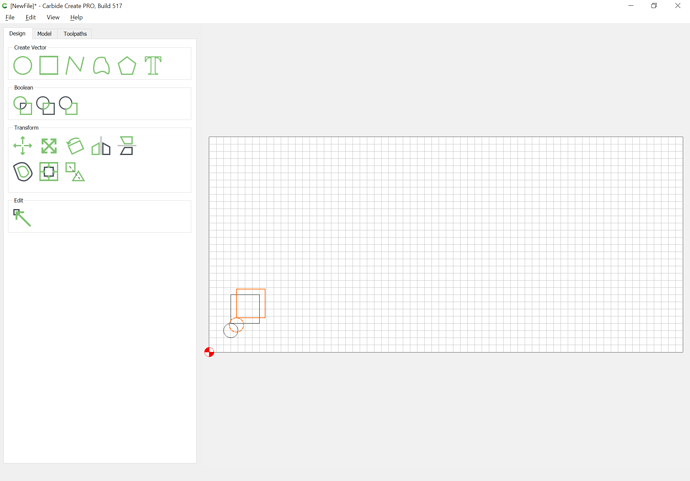

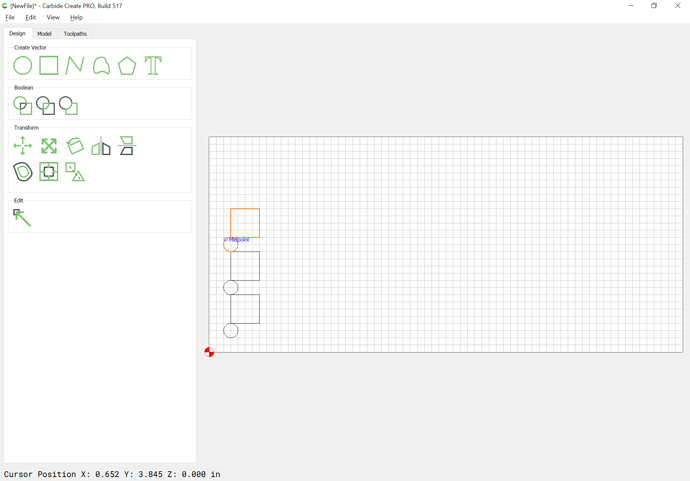

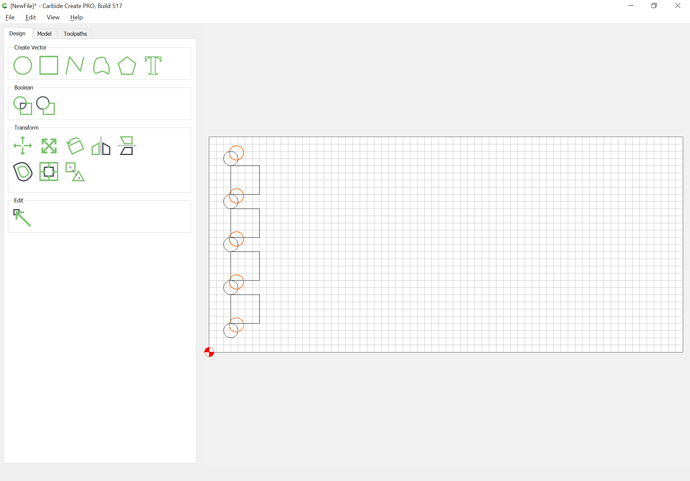

Then duplicate and drag and duplicate until one has a complete column:

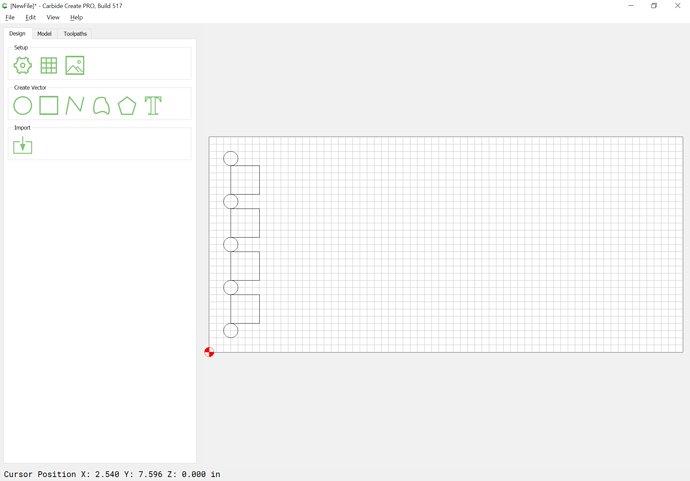

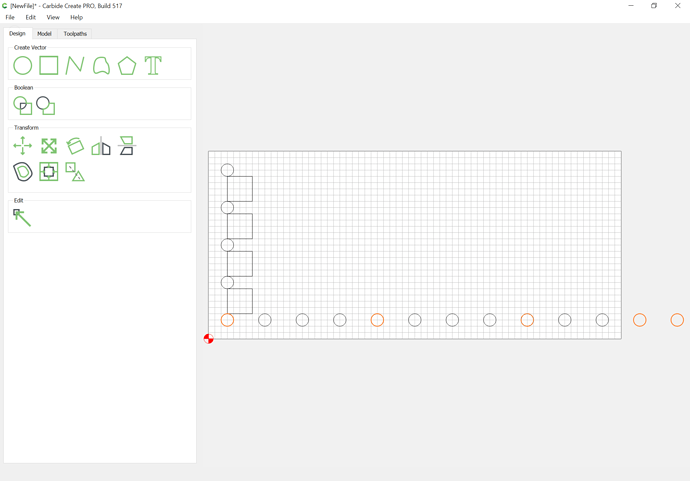

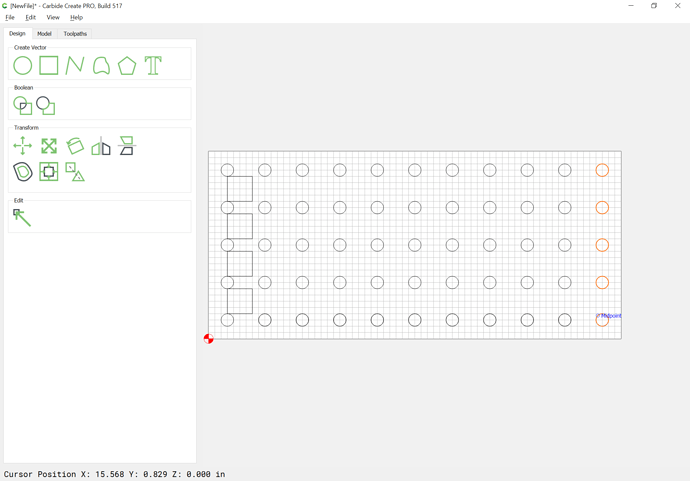

Then select the column of circles:

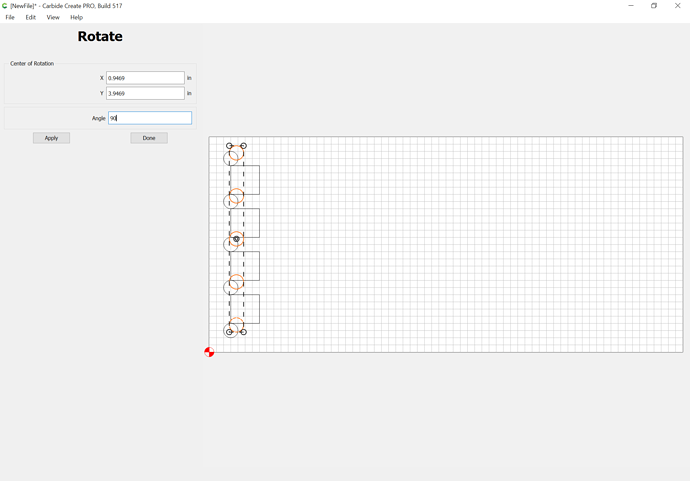

Duplicate it:

Rotate 90 degrees:

Apply | Done:

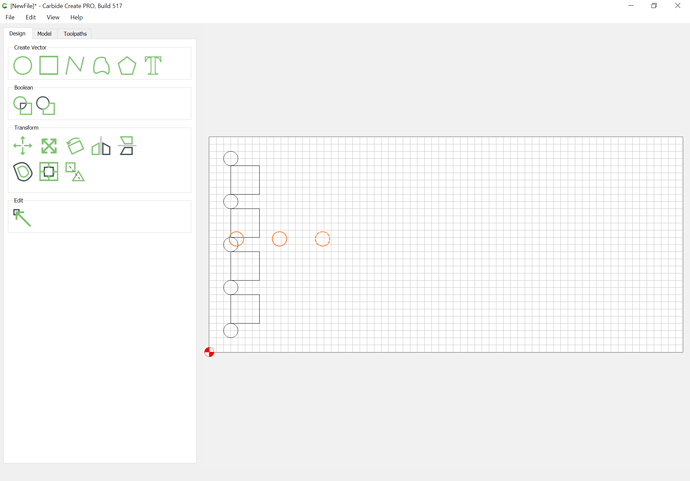

Drag into position:

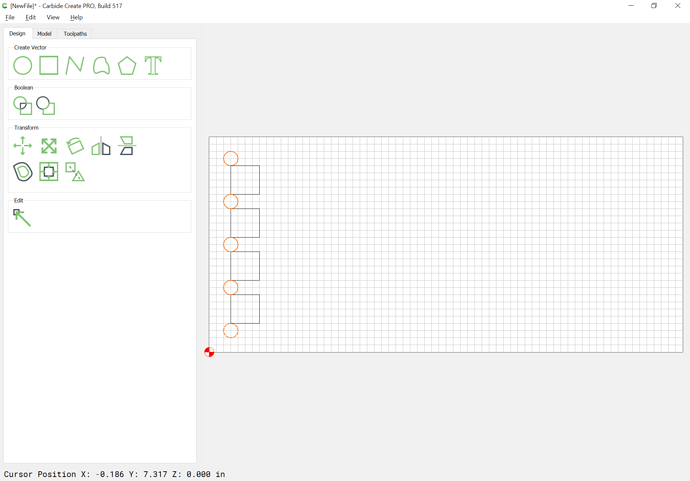

Duplicate, drag duplicate into position and repeat until one has enough:

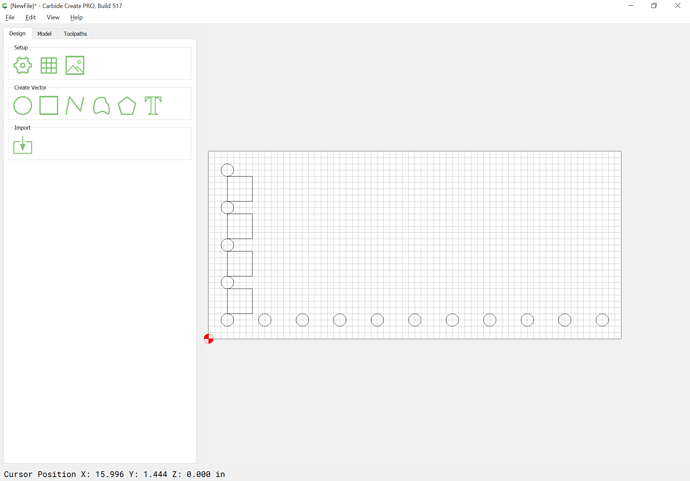

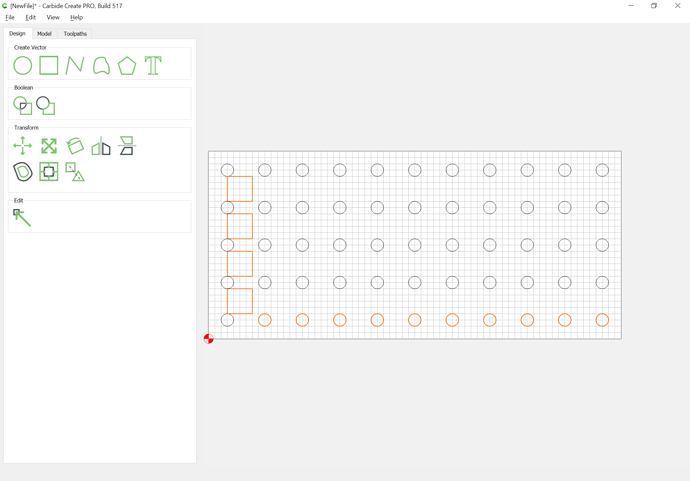

Delete the duplicate and unnecessary circles:

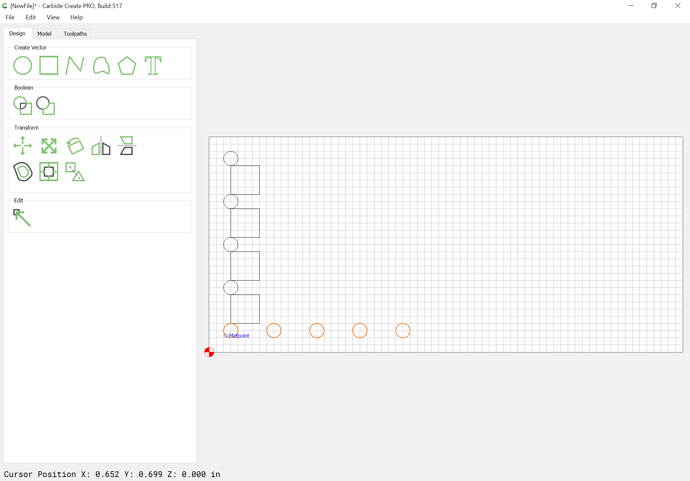

Select the column and duplicate:

Drag into position:

Repeat until all are done:

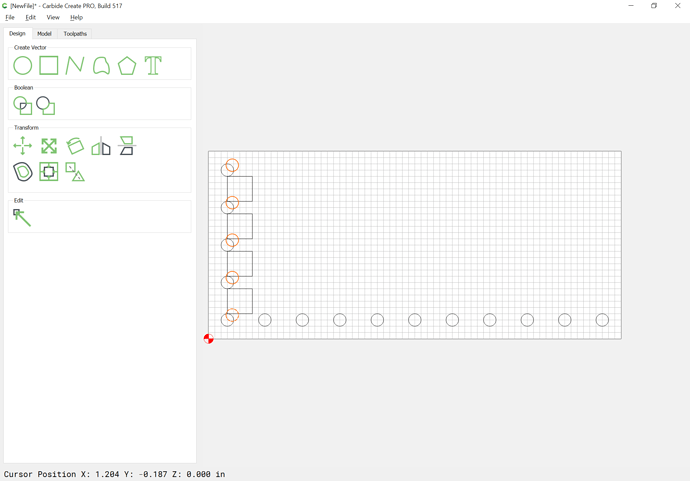

Delete the spacing geometry and the duplicate circles in the lowest row:

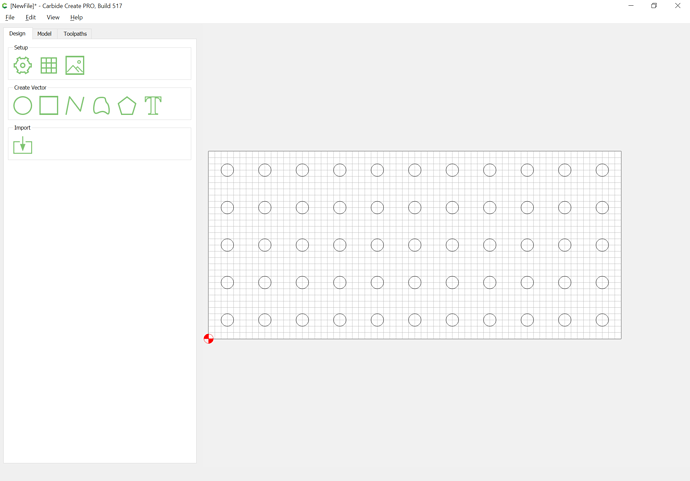

Arriving at:

Or, just draw and position things based on their matching up with the grid.