Clamp as close to the cut as you can, and try to have the entire length clamped. For example, if you clamp to the edge of a bench, put a strip of wood on top and use clamps at both ends. That helps a lot with noise and getting a clean cut.

Do you know, is it possible to get similar levels of noise out of a bandsaw? The hacksaw does work but if I could save my arms, that’d be great

My Laguna 14Twelve Bandsaw measures 55 dBA at operator ear level when not cutting, so maybe, depending on what and how you cut.

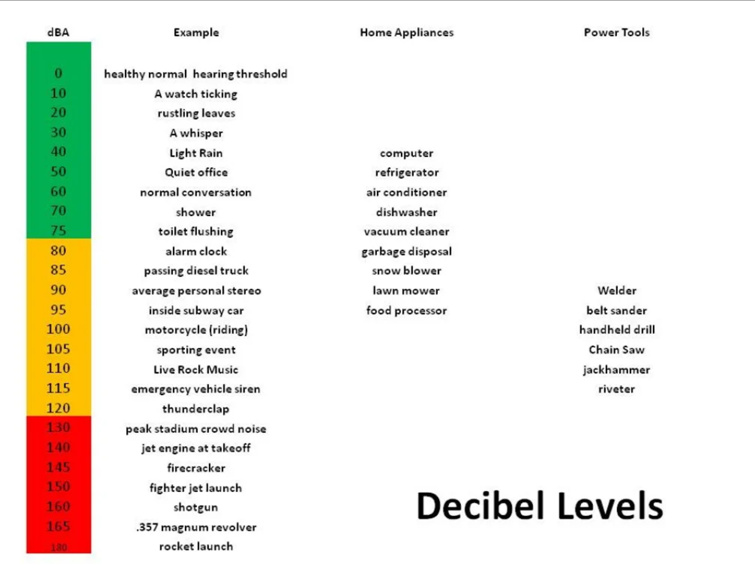

Our noisy world!

Sawing by hand can be a workout, but practice makes it pretty efficient.

Some bandsaws are very quiet when not cutting, as @gmack said. Handhelds are often noisier than standard (cabinet?) units, because there is less mass to damp out noise from the motor and gears, they usually need fans, with the associated openings in the case, making the motors more exposed, but they are better than they used to be. The transition to BLDC rather than universal (brushed) motors has done a fair bit to quiet the motor itself.

Unfortunately, in my experience, much of the noise is during the cut. Same principal applies to reduce noise as with a hand saw. The better the restraint of the material and the better the damping, the lower the noise level. Especially when cutting sheet and plate. It acts like a soundboard for a piano.

A less rigid machine makes it worse, and adjusting the blade speed and cutting force also have a pretty big effect.

Conjecture: a thin layer of wood between the piece being cut and the table (or foot of a handheld) of the bandsaw- 3mm door skin, for example- will control noise pretty well, at least for thin flat stock (<10mm thick).

are you using the rage blade as an alternative on a regular abrasive wheel chop saw or a slower high torque dry cut saw?

I know the carbide blades don’t last long at high RPMs and are only meant to be used on dry cut saws but I would buy a rage blade for my abrasive wheel chop saw if it would hold up. I don’t want to drop $500.00 on a dry cut chop saw.

If anyone is interested I have a Milwaukee pitta bandsaw used little and can ship in US.

Phil

Actually, using it in a compound power miter saw. Use the same blade in a table saw. Used to have an abrasive wheel chop saw, but it never made a straight cut and got sick of trying to make it work well. Works great in both, I’ve cut aluminum and steel (with a nonferrous blade for aluminum, ferrous for the steel) and it works great. Cuts are clean.

Which ferrous blade?

The orange TCT steel, aluminum and plastic blade for aluminum: https://www.amazon.com/Evolution-Power-Tools-RAGE255Blade-Multi-Purpose/dp/B00249JDY4/ref=sr_1_3?dchild=1&keywords=rage+saw+blade&qid=1597615868&sr=8-3

The blue “STEEL” blade for mild steel: https://www.amazon.com/Evolution-Power-Tools-10BLADEST-52-Tooth/dp/B001QF9VQ2/ref=sr_1_2?dchild=1&keywords=rage+saw+blade&qid=1597615810&sr=8-2

Your saws have 1 inch arbors?! What speeds do they run at?

Dewalt probably has a 5/8" arbor, as do most/all woodworking/non-ferrous metal saws with 10" blades. They also run at 3450 RPM, at least in the 60Hz parts of the world. That speed would not be good and would likely be quite unsafe with those blades.

That’s what’s stopped me picking up one of the Evolution blades for my bosch circular.

OTOH, learning how to cut efficiently cleanly and straight with a handsaw is a basic skill all apprentices should master…

Someday I’ll slow down my miter saw with a Variac and see how/if it can cut anything.

Or go full Julien and just use a really high speed camera?

Jeremy Fielding gave that a shot and it didn’t go well (as he expected, to be fair): https://www.youtube.com/watch?v=gMVIdDKgG5A

Thanks! I suspect that the output current limits of his Variac and DC speed control limited their performance. ![]()

He should have used a BLDC motor

Maybe a Modwaukee?

Lots of good advice here.

My number one suggestion is order from xometry supplies and have it cut to size. They are one of the cheapest around, ship fast, regularly have deals. You only pay for what you need and I don’t think you’ll ever make up the cost of your tools and time trying to cut down larger stock.

That said, sometimes you have something that needs to be cut so you can make a small part out of it

I have used the harbor freight horizontal band saw, it works well for cutting bar stock.

I currently use my Ryobi 7 1/4" miter saw with a blade that I picked up from Lowe’s. It works decently well. I drilled some holes in the base so I can clamp the pieces down. I’ve cut some pretty small blocks out that way. My blade is missing a tooth, but I think it was 1/2" polycarbonate that did that.