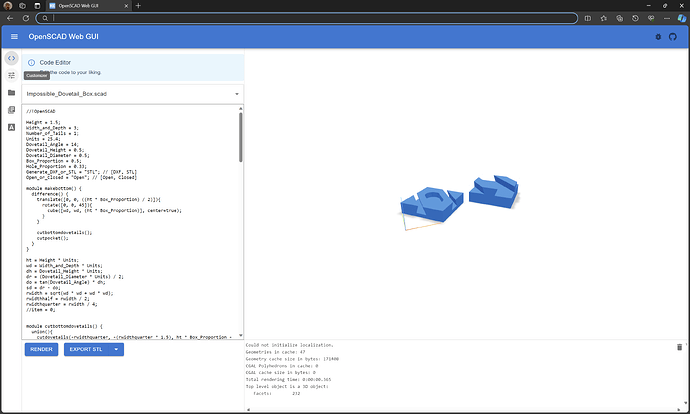

For folks who don’t have OpenSCAD installed it is available at:

Click on the icon for “Customizer”

to adjust things and choose “DXF” rather than STL to be able to export a DXF or SVG:

EDIT: Note that the image below shows an incorrect construction caused by an error (since corrected) in the OpenSCAD code — adjusting for that error (and finding it in a check of the files) is shown below.

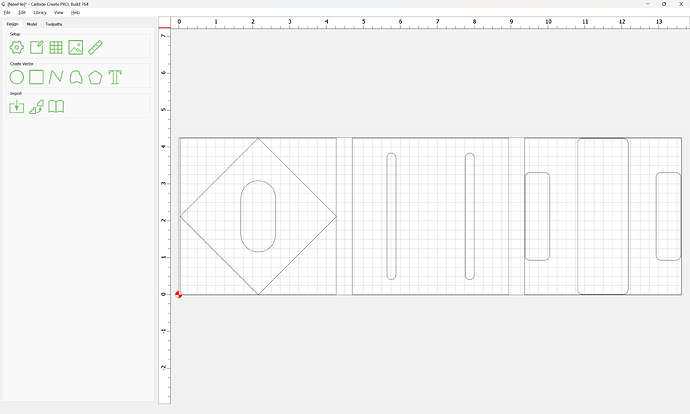

which may then be loaded into Carbide Create:

to have toolpaths created.