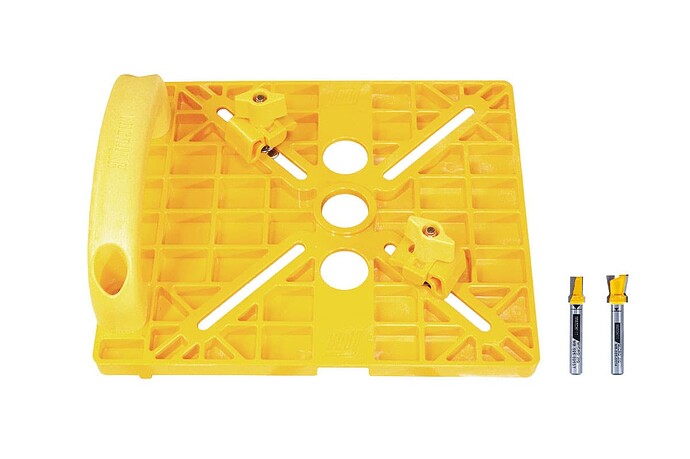

I just purchased the micro jig cnc match fit kit, I need to make a grid Spoilboard 4” horizontal and vertical- I was going to make the Spoilboard 23.5x 47.5 in , but am not having any luck designing the Spoilboard and tool paths

Can anybody help

What are you having trouble with specifically and what software are you using?

Note that Carbide Create does not preview tooling which does undercuts, so you will need to just set up a No Offset Contour for the dovetail tool and take where it cuts on faith/wireframe preview.

indicates that there are “free spoilboard plans” — what do they show?

It seems you just need a series of lines which make the cut and begin/end somewhere the tool can plunge…

I have the MatchFit system in my shop. I bought the jig they sell to manually router the clearance slots and follow up with the dovetail bit.

The jig requires you have a router that can use Porter Cable style bushings. I think you could use a router without the PC bushings but if your router moves it messes up the whole operation. I use a Dewalt palm router. You first hog out the grooves and then follow up with the dovetail bit. You could just use the dovetail but but you are removing a lot of material at once for a palm router. Plus you get a cleaner result if you plow out the grooves first and then the dovetail bit.

I know this is not a Shapeoko solution but you can use the system for other things round the shop. I made a piece of mdf up to cut straight edges on irregular stock. It can also be used as a tapering jig.

I did use my Shapeoko to make the tapering jigs.

I also have a Jessem Pocket Mill Pro and Master Doweling jig that has its own workstation for the Jessem that uses the MatchFit clamps.

If you dont have a jointer it cuts a very nice straight edge. You are limited in length but for making small table top glue ups it works great.

I made a new assembly bench that has the MatchFit system and it works great.

i have created a toolpath for a spoil board match fit cnc grid .

the first tool path is a 1/4" end mill 5/16 deep

the 2nd toolpath cut the outer perimeter 1/4 " wide and 5/16" deep

the 3rd toolpath i made a duplicate tool path and set it for one pass of 3/8" deep and it would not let me have a tool bit change to install a micro jig dovetail bit, and it did not work,

there is no dovetail tool in the carbide create pro library,

is there a way to have this work ? does anyone know ,please see file

16.25 x 16.25 test grid.c2d (96 KB)

Tool geometries which undercut are not supported in Carbide Create.

The usual approach is to make a placeholder tool, work up reasonable feeds and speeds, cut the central channel clear w/ a square tool, then use a No Offset Contour to make the cut where one wants, but note that it will be necessary to double back.

Alternately, if it’s a short distance a Keyhold toolpath may be used.